Bearing inner ring assembly cylindrical roller deflection detection method and device

A technology of cylindrical roller and detection device, which is applied in the direction of measurement device, mechanical measurement device, and mechanical device, etc., achieves the effect of reducing detection cost and labor, simple overall structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail in conjunction with accompanying drawing and specific embodiment:

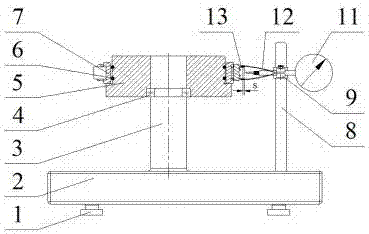

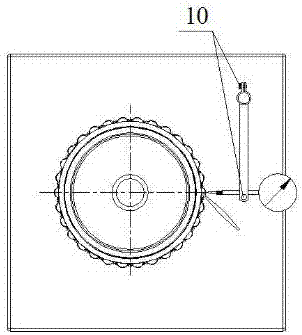

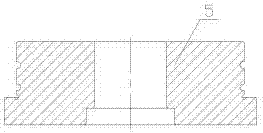

[0023] Such as figure 1 , figure 2 As shown, a detection device for the sinking amount of the cylindrical roller of the bearing inner ring assembly, the detection device has a mandrel 5 for supporting the inner ring assembly 7; combined with image 3 , Figure 4 , the mandrel 5 is a stepped shaft with an annular boss on the lower part of the outer wall surface, and the annular step forms a supporting step for supporting the inner ring assembly 7; the inner ring assembly 7 is sleeved on on the mandrel 5, and its lower end surface fits with the annular step; the outer diameter of the annular step is not larger than the rib outer diameter of the inner ring assembly; the inner ring assembly 7 and the The mandrel 5 mentioned above is loosely fitted; the rubber ring 6 is arranged between the inner ring assembly 7 and the mandrel 5; the rubber ring 6 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com