Digital controlled small hole machine electrode rotating control device and method

A technology of a rotary control device and a small hole machine, which is applied in the direction of accessory devices, manufacturing tools, electric processing equipment, etc., can solve problems such as large electrode shaking, gap discharge out of control, affecting the shape of the processing hole, dimensional accuracy and processing efficiency, etc. Achieve the effects of improving processing quality and efficiency, reducing gap discharge control, and improving system processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

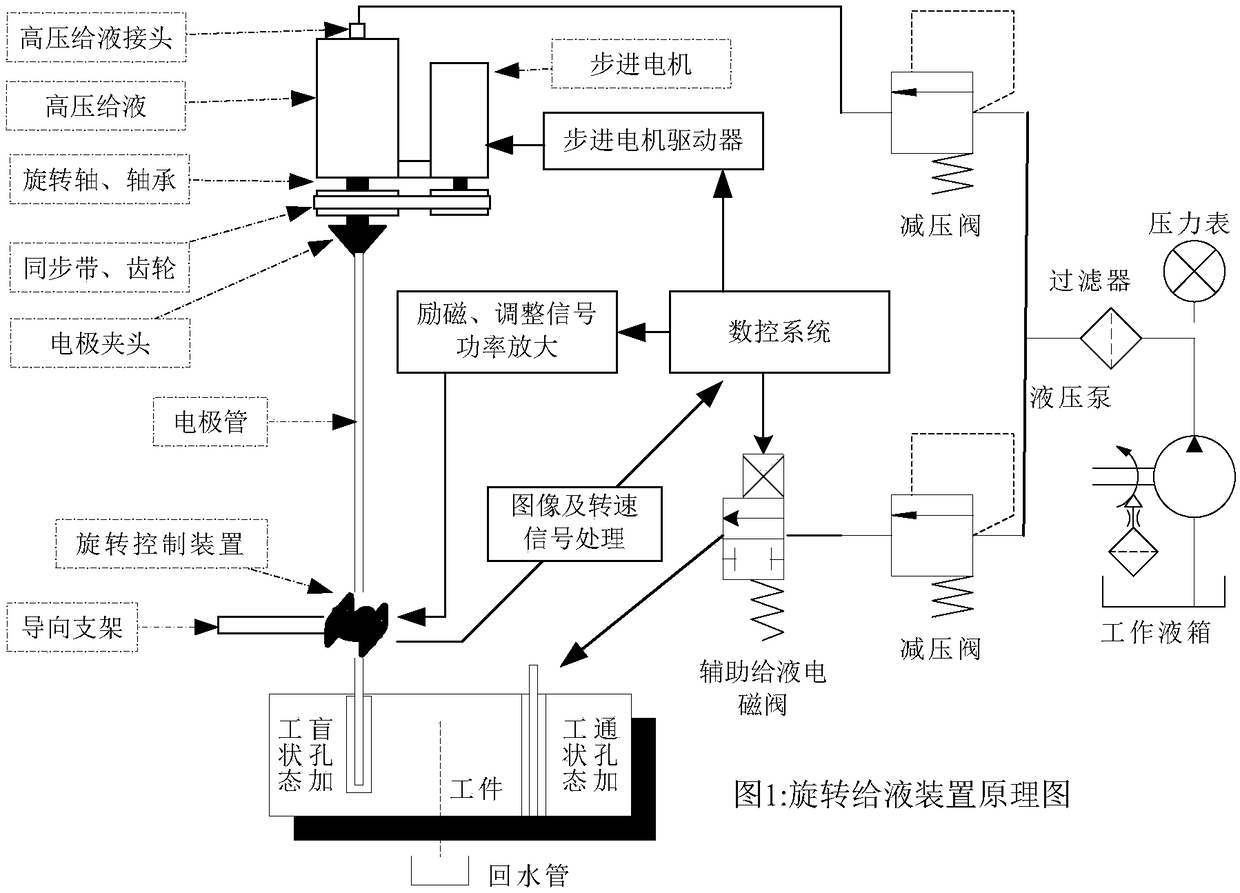

[0048] figure 1 It shows a specific embodiment of the numerical control small hole machine of this application, which is the same as the traditional numerical control small hole machine, it also includes: electrode tube 3, stepping motor, numerical control system, high pressure liquid feeder and other components. Wherein the stepper motor is connected with the electrode tube 3 through a rotating head (or electrode chuck) to drive the electrode tube 3 to rotate. The electrode tube 3 is vertically arranged, the rotating head is located at the upper end of the electrode tube 3, and the stepping motor drives the rotating head by means of a synchronous belt and a synchronous wheel.

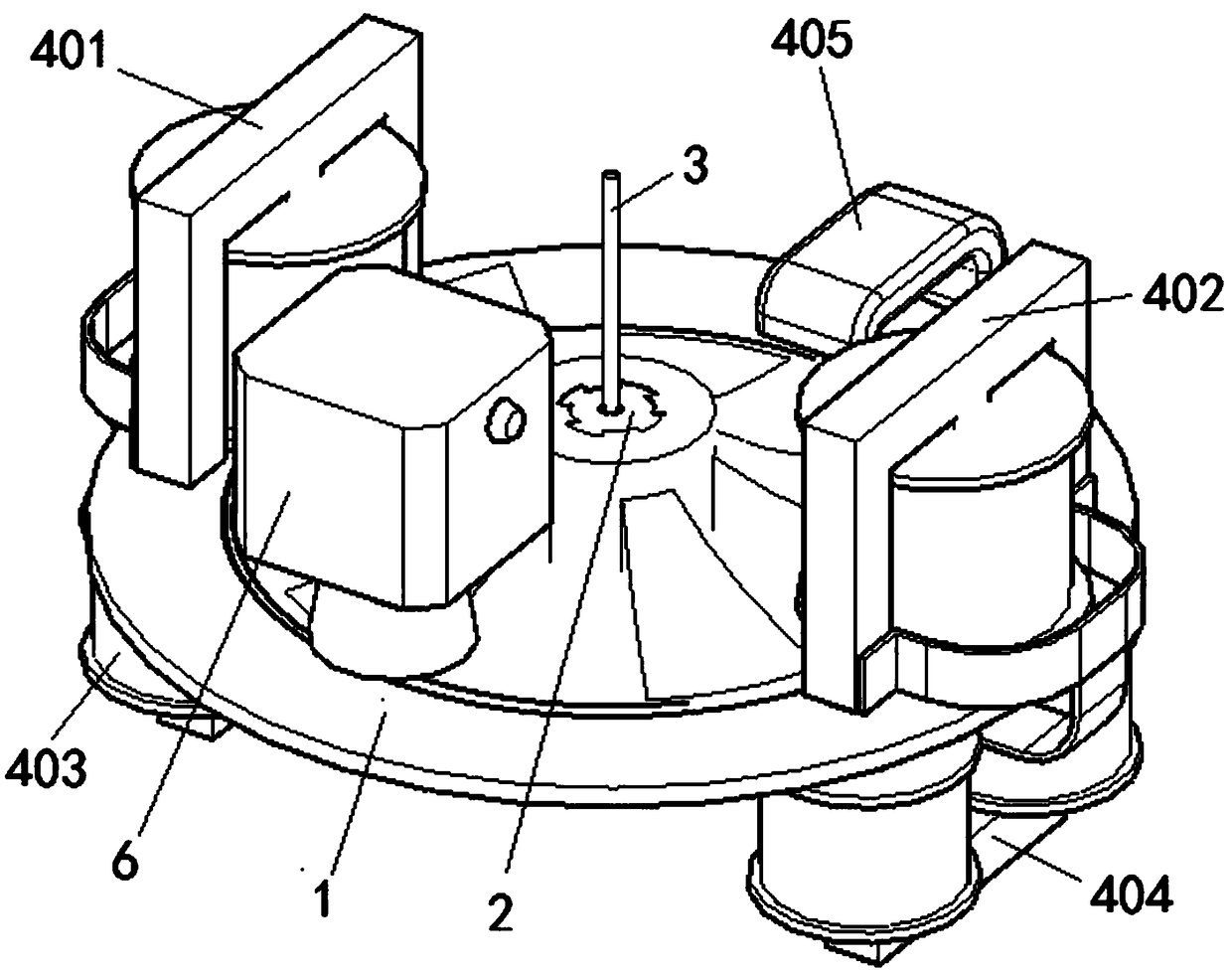

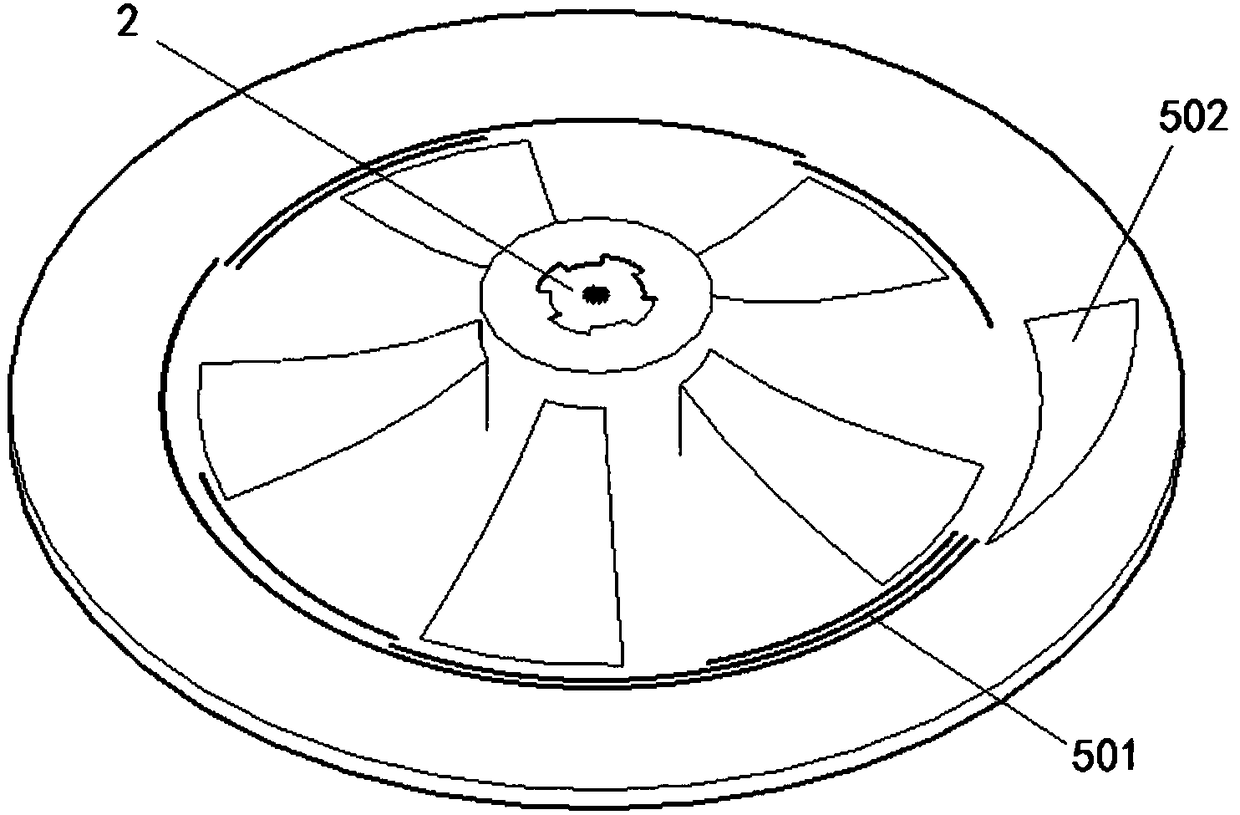

[0049] The key improvement of this embodiment is that it is also equipped with a CNC small hole machine electrode rotation control device, refer to figure 2 As shown, the device includes a rotor 1 , a stator, a rubber ring 2 and a line scan camera 6 . Among them: the rotor 1 has a central hole with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com