Contact characteristic analysis method based on three-dimensional microscopic surface morphology

A technology of surface topography and analysis methods, applied in special data processing applications, measuring devices, instruments, etc., can solve problems such as failure to consider the influence of contact characteristics, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, and embodiment the concrete method of the present invention is described

[0031] 1. Acquisition of microscopic surface topography

[0032] The specific steps to obtain the surface topography by using the three-dimensional surface topography measuring instrument are as follows:

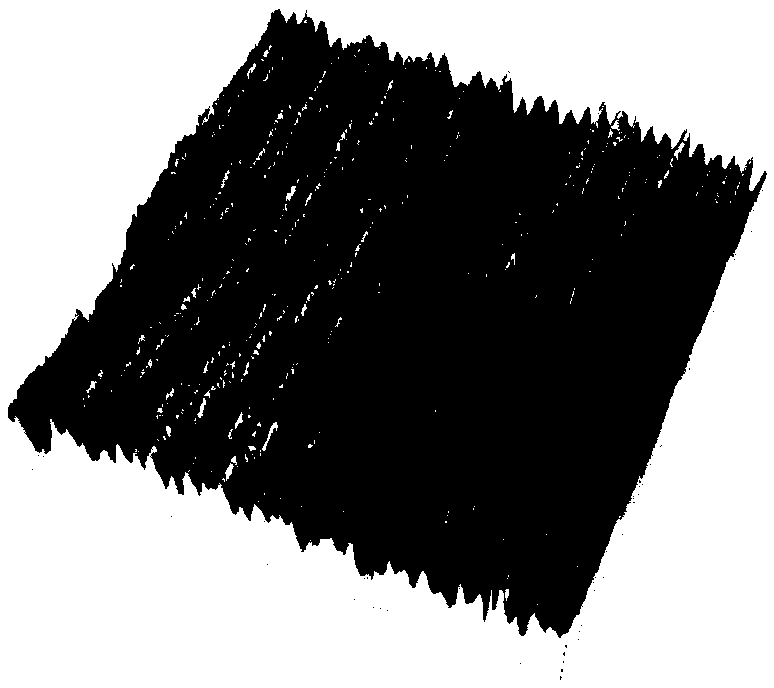

[0033] According to the desired resolution, select an optical measurement probe with a suitable range; set the size of the sampling area and the sampling step. First, put the workpiece in an alcohol solution for ultrasonic cleaning for 15 minutes. After cleaning, dry the workpiece with compressed air and clean the surface of the specimen before measurement to ensure that the surface is free of impurities. Secondly, set the sampling area and sampling step in the acquisition software. In this example, the size of the sampling area is 3mm×3mm, and the sampling step is 0.004mm. The obtained surface is as figure 1 shown.

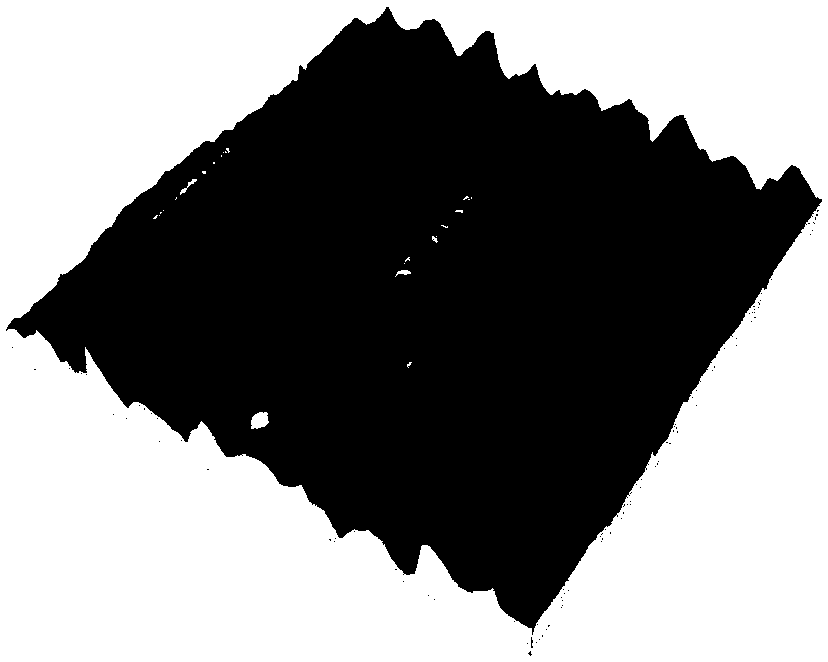

[0034] 2. Multi-scale de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com