Building method of carbon fiber composite material cutting model

A technology for composite materials and establishment methods, which is applied in the research field of cutting and processing of carbon fiber composite materials, and can solve problems such as establishment methods that do not consider interface cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

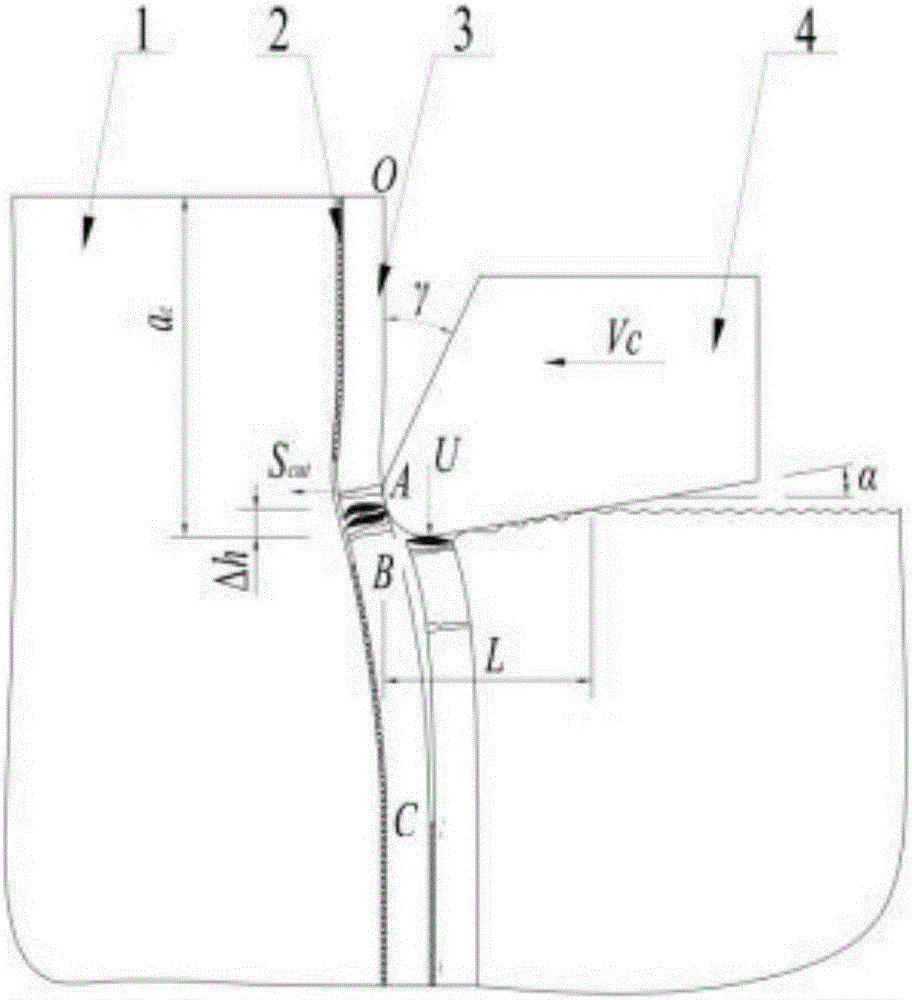

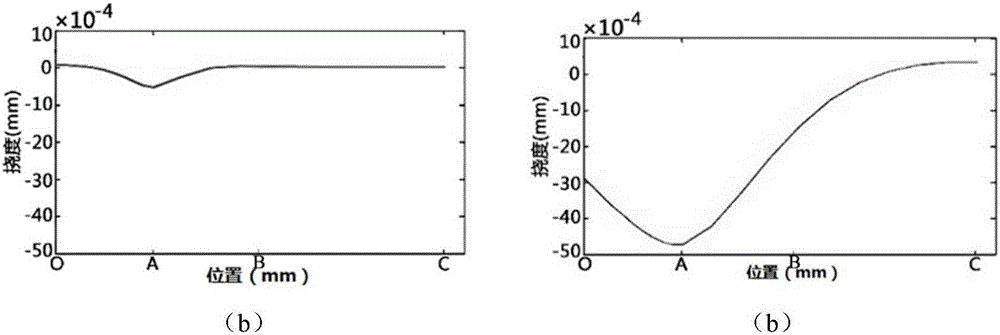

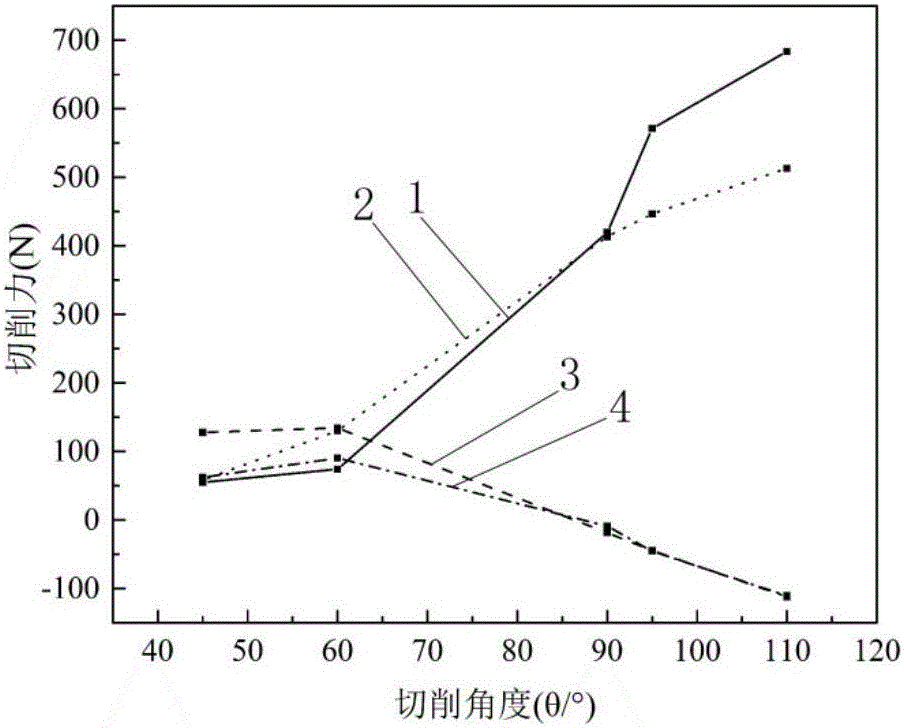

[0099] Calculate the depth of cut a from the conclusion of the first step c 20μm and 50μm fiber deformation and interface cracking respectively. The material parameters of the carbon fiber composite material 1 used and the matrix 2 and fiber 3 are shown in Table 1. The cutting speed is V c =500mm / min, cutting angle θ=90°. The result is as figure 2 shown. When the minimum depth of cut is 20 μm, the fiber 3 only undergoes small local deformation under the action of the cutting force, and the fiber 3 shears and breaks, but the interface does not crack, as shown in figure 2 As shown in (a), when the maximum depth of cut is 50 μm, the fiber 3 bends and deforms greatly under the action of cutting force, the interface cracks first and then the fiber 3 bends and breaks, as shown in Fig. figure 2 (b) shown. Through comparison, it is found that when the arc radius of the blade is much smaller than the fiber radius, the local contact stress is greater than the bending stress, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com