Method for predicting milling surface errors based on dynamic workpiece clamping system

A technology of milling processing and prediction method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as difficult processing of weak rigidity parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

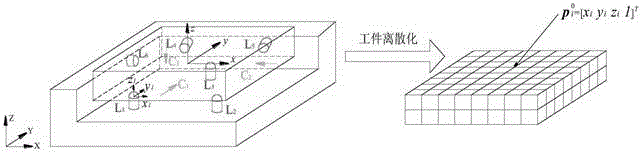

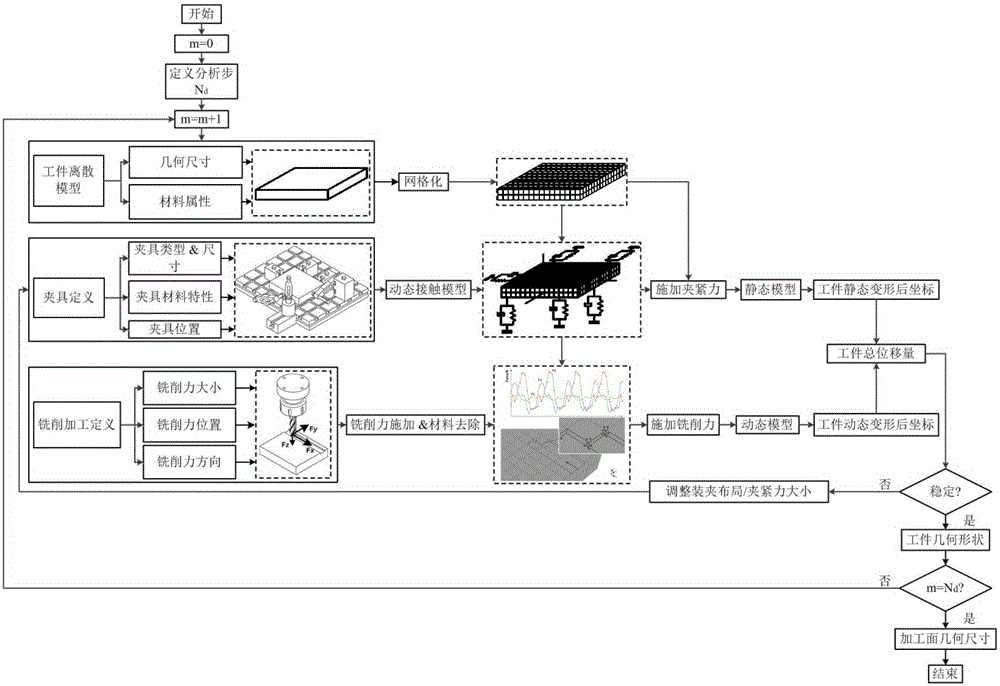

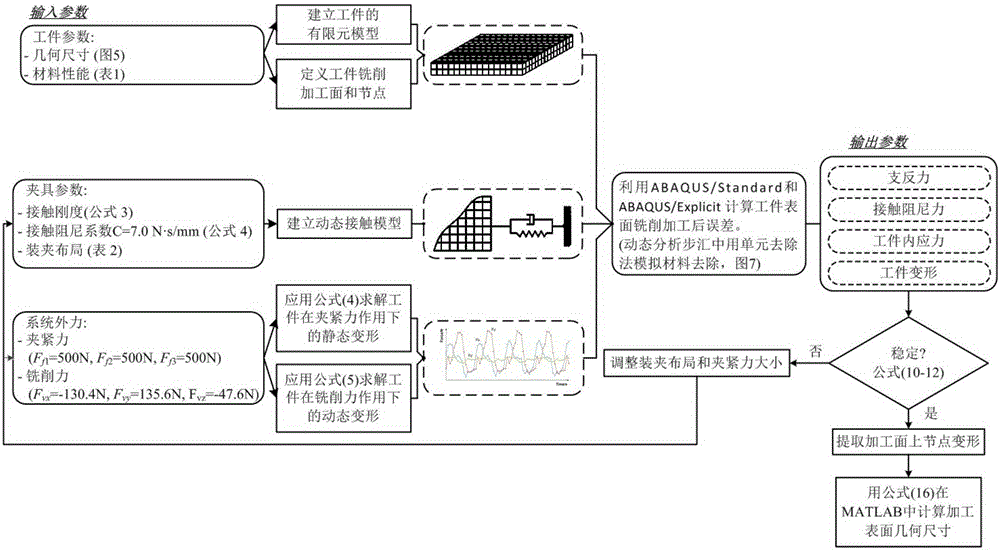

[0042] The following is a specific simulation example based on the established workpiece dynamic milling error prediction method.

[0043] Firstly, the workpiece is a hexahedral flat plate with a size (length×width×height) of 100mm×100mm×14mm. Through milling, an open slot with a size of 100mm×10mm×1mm is processed on the workpiece. The 3-2-1 positioning criterion is adopted when the workpiece is processed. The material properties of the workpiece and the positioning / clamping components are shown in Table 1, and the layout of the positioning / clamping components is shown in Table 2. The clamping forces at C1, C2, and C3 are all 500N .

[0044] Table 1 Material Properties of Workpiece and Positioning / Clamping Components

[0045]

[0046] Table 2 Positioning / Clamping Component Coordinates

[0047]

[0048] ABAQUS6.11 software is used for finite element calculation, and the finite element analysis example model is established. The finite element model adopts the 8-node hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com