A machining error prediction and control method for mesoscale parts

A technology for mesoscale parts and machining errors, which is applied in the field of modeling and prediction of multi-station manufacturing errors of mesoscale parts based on scale effects, can solve the problems of small rigidity of tools and workpieces, affecting machining accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

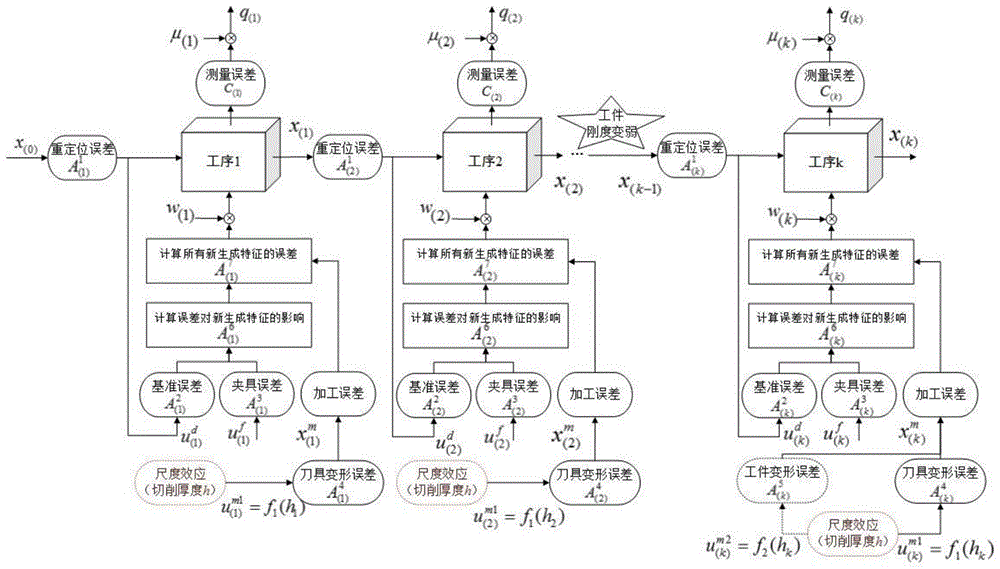

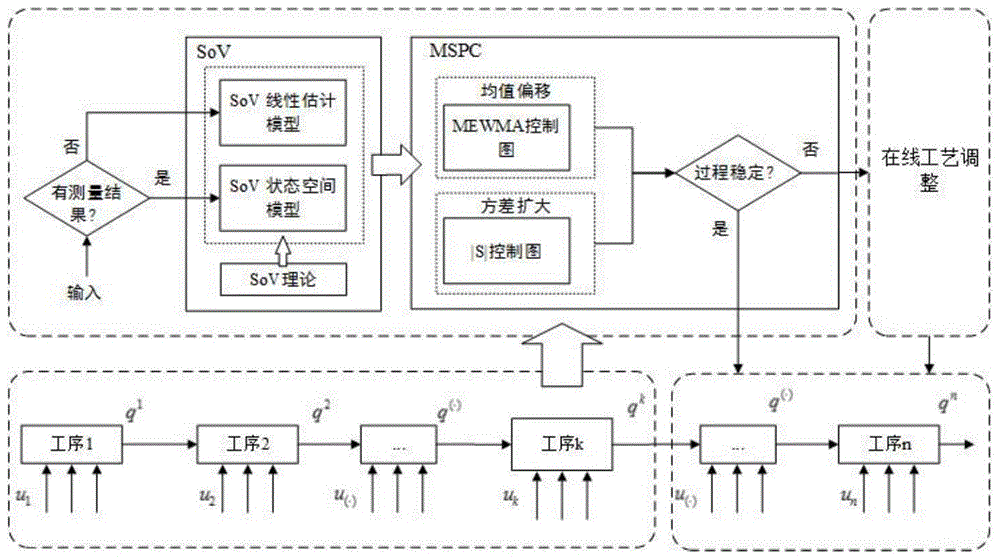

[0034] A method for predicting errors in multi-station manufacturing of mesoscopic scale parts based on the scale effect proposed in this embodiment, specifically includes the following steps:

[0035] Step 1. Carry out feature analysis for the mesoscale parts to be predicted, extract the processing accuracy requirements of the processing features, and determine the key part feature KPC according to the processing accuracy requirements.

[0036] Mainly carry out the storage, processing and analysis of historical data including mesoscopic cutting characteristics, equipment status information and workpiece quality information. The cutting data is obtained through basic experiments, and the relevant data of equipment and workpieces are obtained through historical databases and sensor networks during processing. , through this module, the key part characteristics (Key PartCharacteristics, KPC) and key control characteristics (Key Control Characteristics, KCC) can be analyzed to pro...

Embodiment 2

[0092] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0093] The material of a certain block part is 310S stainless steel, and the workpiece is processed in two steps: first, surface C is used as the main positioning reference, and surface A is milled; then, surface A is used as the main positioning reference, and groove 1 and groove 2 are milled. Use a carbide end mill with a diameter of 2mm for milling of groove 1 and groove 2, the spindle speed n=8000r / min, the feed per tooth f z = 0.004 mm / z. See Table 1 for specific procedures and requirements.

[0094] Table 1 Workpiece processing procedures

[0095]

[0096] The analysis of the manufacturing system and process shows that the main factors affecting the manufacturing accuracy of parts in process 1 are fixture manufacturing error, reference error and tool deformation error, and the surface S1 and S2 in the processing characteristics of process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com