Method of utilizing finite element modeling to judge whether turntable bearing meets requirements

A slewing bearing, a technology that meets the requirements, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of high computer configuration requirements, calculation failure, long calculation time, etc., meet the reduced requirements and shorten the calculation time , the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples.

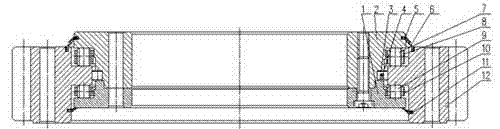

[0027] For example, the structural form of the slewing bearing used by a certain main engine is a three-row roller slewing bearing, as attached figure 1 As shown, it mainly consists of inner rings (1, 2), rolling elements (3, 7, 9), cages (8, 10), spacer blocks (4), sealing rings (5, 6, 11), outer rings ( 12) Composition, wherein the upper row of rolling elements are the main thrust rollers, the lower row of rolling elements are auxiliary thrust rollers, and the middle row of rolling elements are radial rollers. The main structural parameters of the bearing are as follows: the diameter of the center circle of the main thrust roller is 5796 mm, the diameter of the main thrust roller is 50 mm, the length of the main thrust roller is 50 mm, and the number of the main thrust ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com