Meshing characteristic analysis method of stripping bevel gear pair which is corrected by considering substrate rigidity

A helical gear pair and characteristic analysis technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems that the elastic deformation of gear teeth cannot be accurately considered, the gear meshing process cannot be truly reflected, and the calculation efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

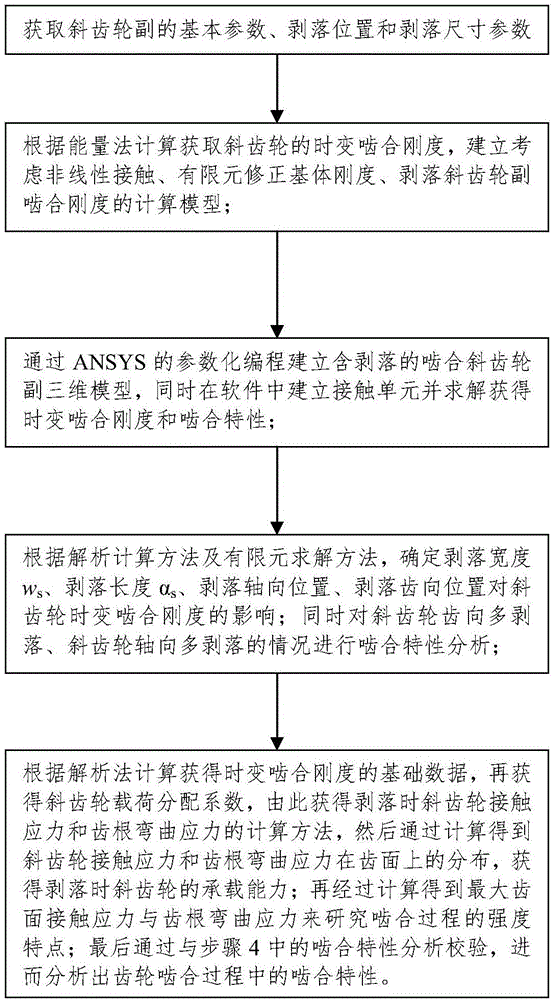

[0083] Such as figure 1 Shown: This embodiment discloses a method for analyzing the meshing characteristics of a spalled helical gear pair considering the correction of substrate stiffness, including the following steps:

[0084] Step 1: Obtain the basic parameters, peeling position and peeling size parameters of the helical gear pair;

[0085] In this embodiment, the basic parameters of the helical gear pair are obtained as shown in Table 1 (see the description in the text for details on the peeling position and size):

[0086] Table 1 Helical gear pinion parameters

[0087]

[0088] Step 2: Calculate the time-varying meshing stiffness of the helical gear according to the energy method, and establish a calculation model that considers nonlinear contact, finite element correction of the matrix stiffness, and the meshing stiffness of the spalled helical gear pair;

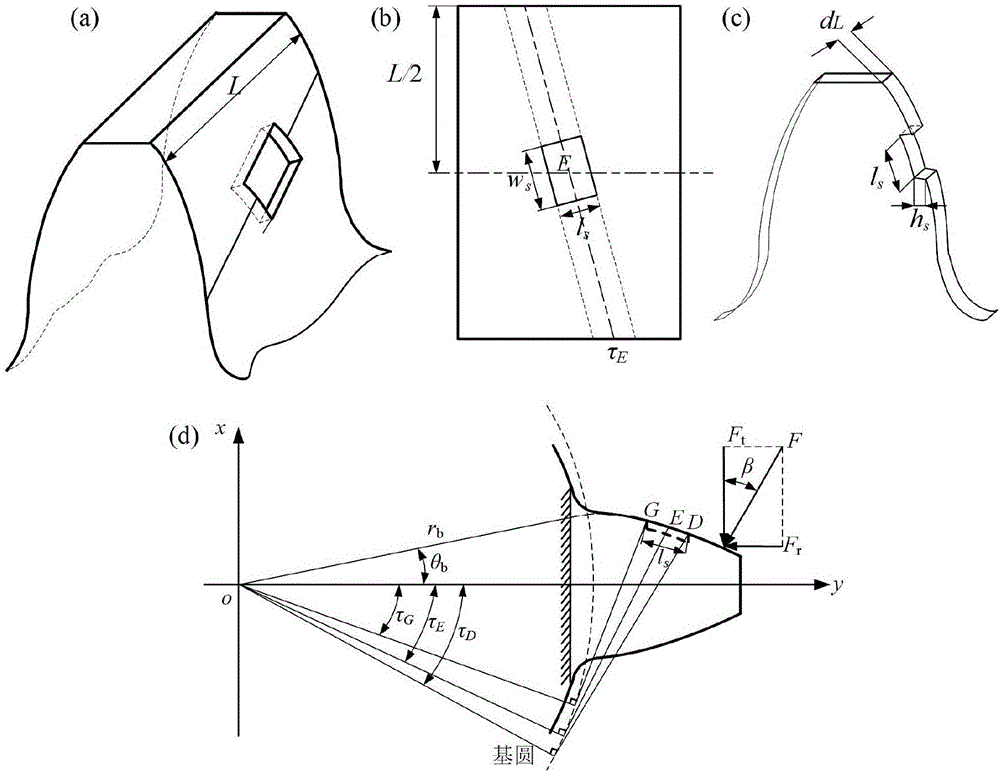

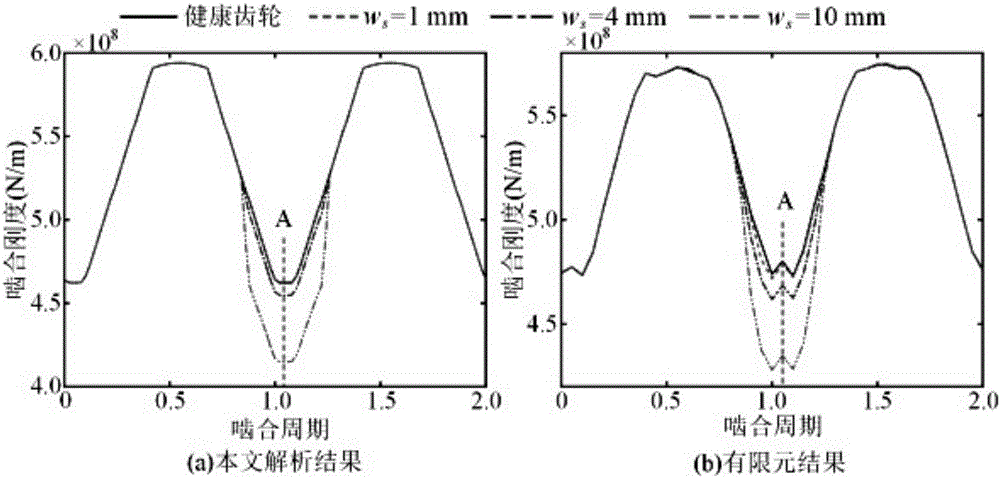

[0089] Step 2.1: Decompose the helical gear pair into N independent and uniform small spur gears along the t...

Embodiment 2

[0122] Such as figure 2 Shown: This embodiment discloses a method for analyzing the meshing characteristics of a spalled helical gear pair considering the correction of the substrate stiffness, including the following steps:

[0123] Step 1: Obtain the basic parameters, peeling position and peeling size parameters of the helical gear pair;

[0124] Step 2: Calculate the time-varying meshing stiffness of the helical gear according to the energy method, and establish a calculation model that considers nonlinear contact, finite element correction of the matrix stiffness, and the meshing stiffness of the spalled helical gear pair;

[0125] Step 2.1: Decompose the helical gear pair into N independent and uniform small spur gears along the tooth width direction, and calculate the parameters of each small spur gear;

[0126] In detail, the teeth of the helical gear pair are decomposed into N independent and uniform thin plate gears along the tooth width direction, L represents the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com