Mesh characteristic analysis method of spalled helical gear pair considering matrix stiffness correction

A helical gear pair and characteristic analysis technology, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve problems such as low calculation efficiency, inability to accurately consider the elastic deformation of gear teeth, and inability to truly reflect the gear meshing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

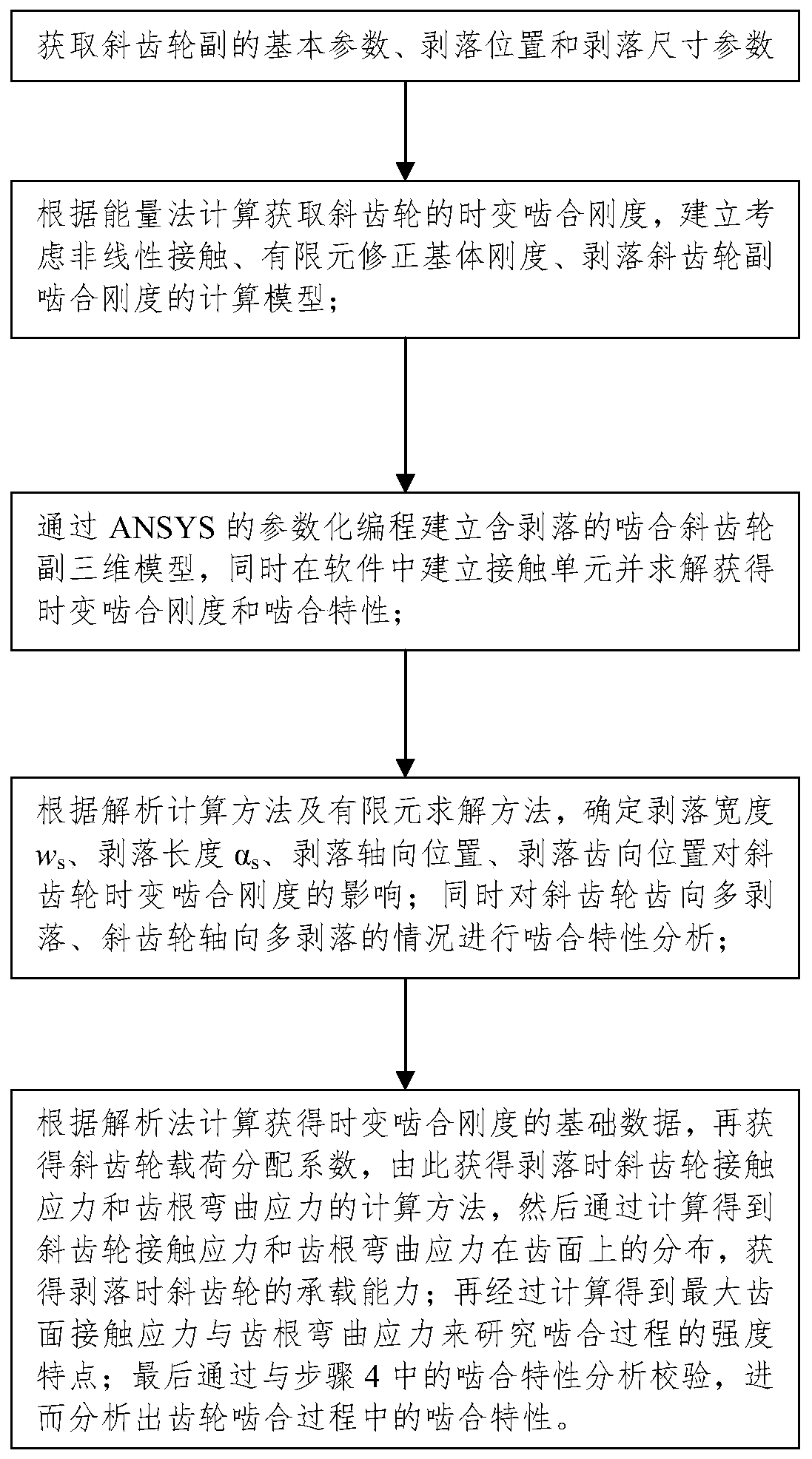

[0083] Such as figure 1 Shown: This embodiment discloses a method for analyzing the meshing characteristics of a spalled helical gear pair considering the correction of substrate stiffness, including the following steps:

[0084] Step 1: Obtain the basic parameters, peeling position and peeling size parameters of the helical gear pair;

[0085] In this embodiment, the basic parameters of the helical gear pair are obtained as shown in Table 1 (see the description in the text for details on the peeling position and size):

[0086] Table 1 Helical gear pinion parameters

[0087]

[0088] Step 2: Calculate the time-varying meshing stiffness of the helical gear according to the energy method, and establish a calculation model that considers nonlinear contact, finite element correction of the matrix stiffness, and the meshing stiffness of the spalled helical gear pair;

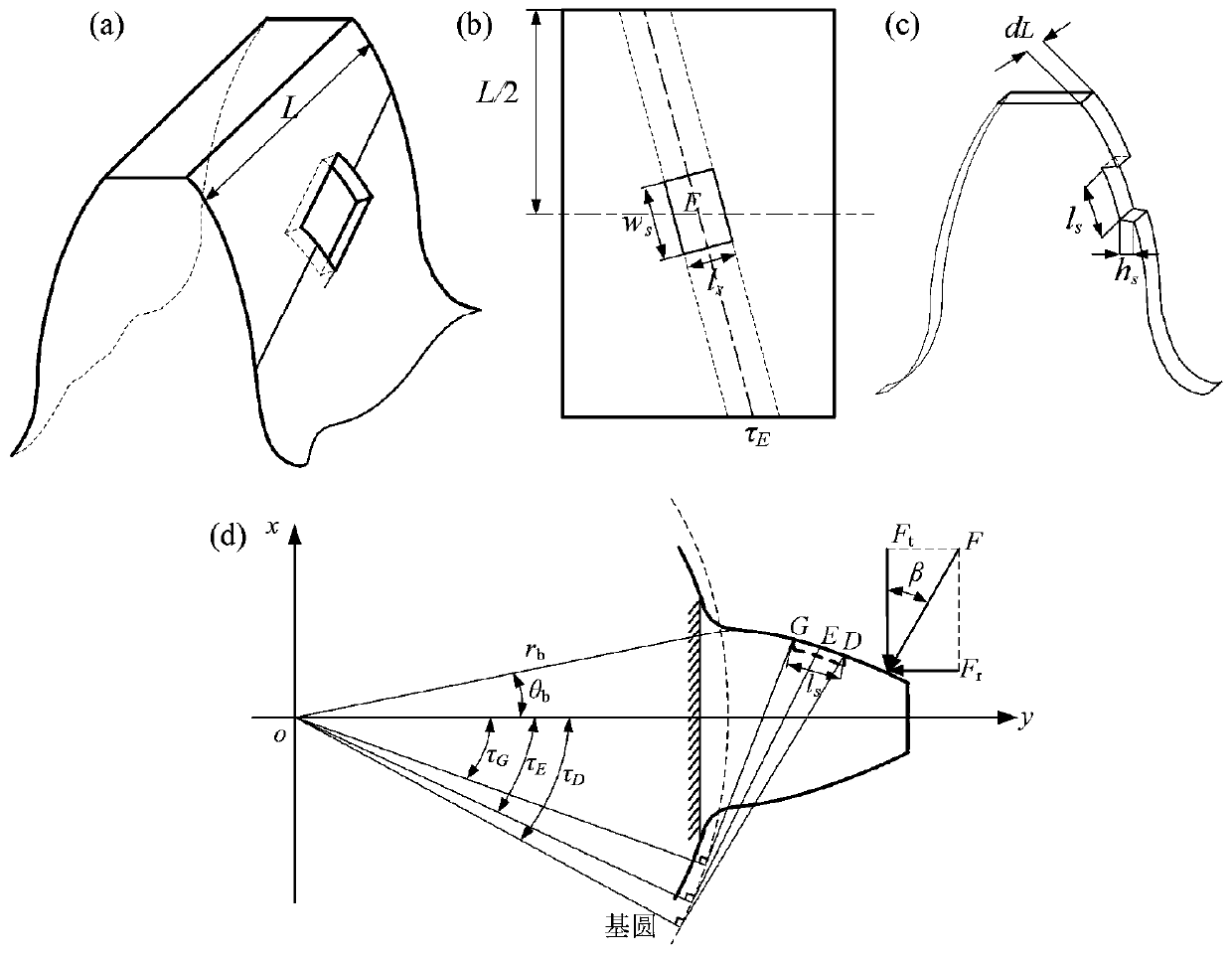

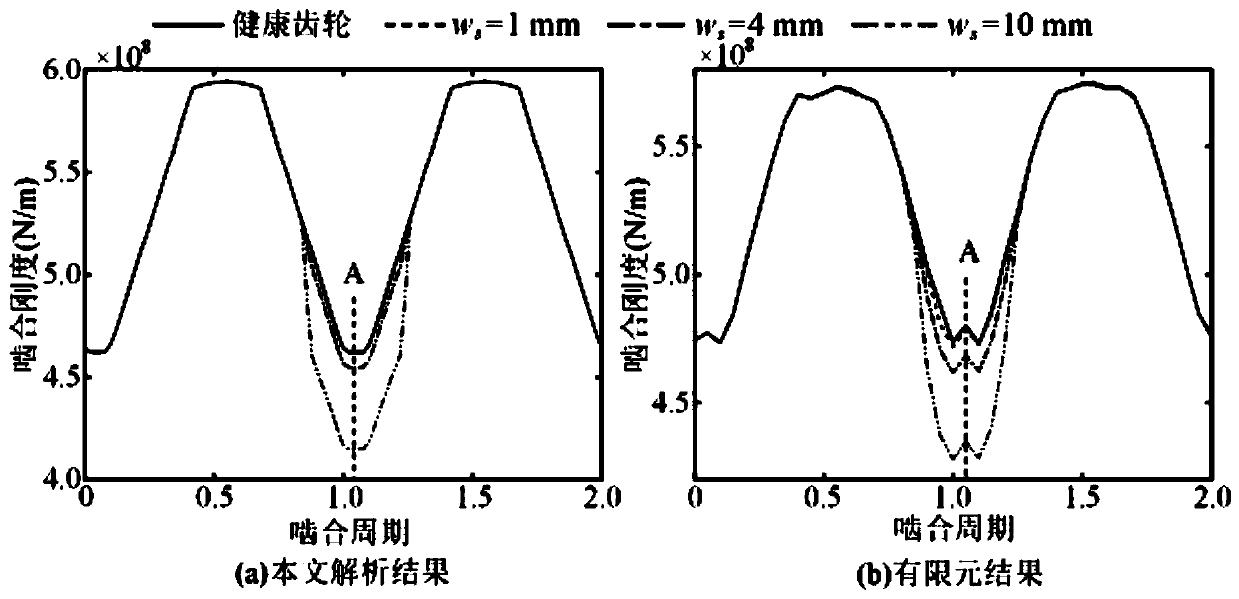

[0089] Step 2.1: Decompose the helical gear pair into N independent and uniform small spur gears along the t...

Embodiment 2

[0122] Such as figure 2 Shown: This embodiment discloses a method for analyzing the meshing characteristics of a spalled helical gear pair considering the correction of the substrate stiffness, including the following steps:

[0123] Step 1: Obtain the basic parameters, peeling position and peeling size parameters of the helical gear pair;

[0124] Step 2: Calculate the time-varying meshing stiffness of the helical gear according to the energy method, and establish a calculation model that considers nonlinear contact, finite element correction of the matrix stiffness, and the meshing stiffness of the spalled helical gear pair;

[0125] Step 2.1: Decompose the helical gear pair into N independent and uniform small spur gears along the tooth width direction, and calculate the parameters of each small spur gear;

[0126] In detail, the teeth of the helical gear pair are decomposed into N independent and uniform thin plate gears along the tooth width direction, L represents the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com