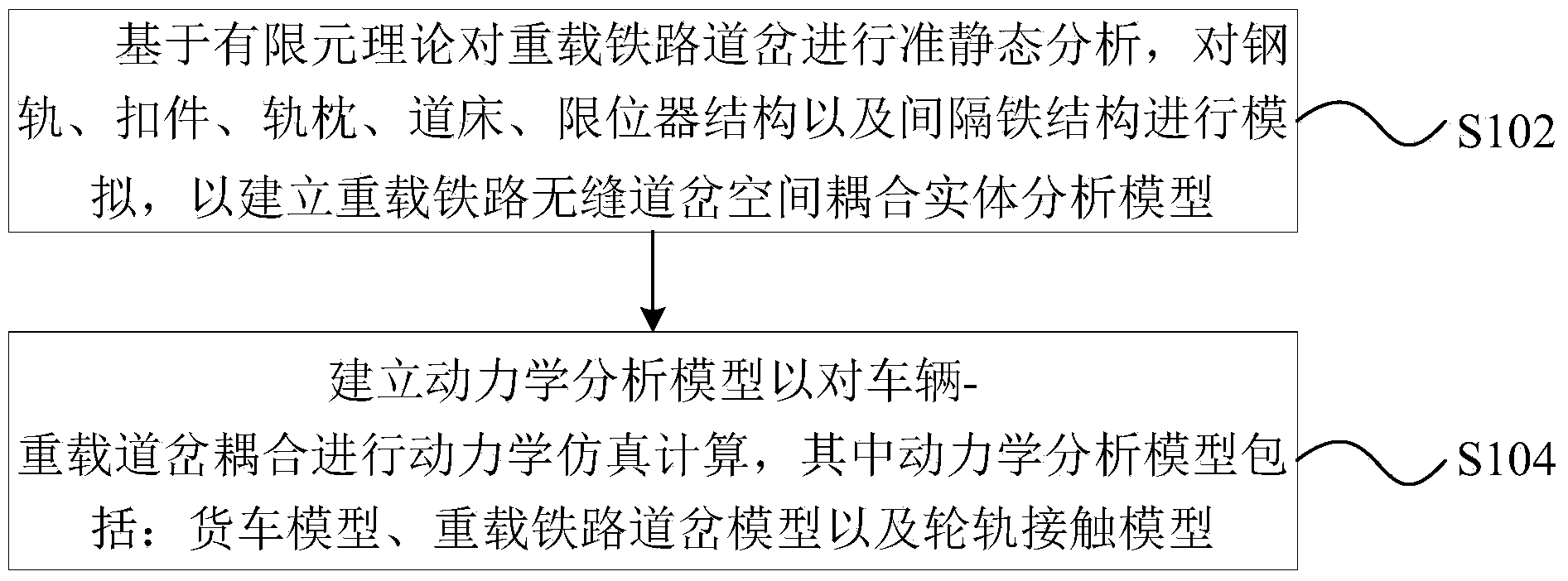

Heavy haul railway turnout static and dynamic design model construction method

A technology for designing models and constructing methods, which is applied in calculation, instrumentation, electrical digital data processing, etc., and can solve problems such as design and maintenance of heavy-duty railway turnouts that are difficult to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] In this embodiment, the No. 12 turnout of the heavy-duty railway alloy steel assembled frog is taken as an example, and the weak parts are analyzed and calculated. The maximum operating axle load of the line is 30t, and the corresponding static wheel load is 150kN. According to the "Railway Track Design Code", the dynamic load coefficient is 1.4 when the vehicle speed is 100km / h. Considering the most unfavorable situation, 2 times the static wheel load is selected as the quasi-static load, and the vertical force of 300kN and the lateral force of 85kN are used as the ultimate strength load. The calculation conditions are shown in Table 1.

[0081] Table 1 Ultimate Load Cases

[0082]

[0083] Note: The vertical force is based on the 30t axle load, taking into account 2 times the dynamic load factor.

[0084]The stress deformation analysis results at the top width of the core rail at 20 mm are as follows: Figure 10 to Figure 12 shown.

[0085] Taking the load appl...

Embodiment 2

[0095] Using the No. 12 assembled frog turnout on the heavy-haul railway, the dynamic characteristics of the system under different crossing modes and different speeds under the condition of axle load 30t are calculated. The extracted calculation indicators include: derailment coefficient, wheel load reduction rate, wheel Rail lateral force, wheel-rail vertical force, rail vertical displacement and vibration acceleration.

[0096] The vehicle speed is 70km / h, 90km / h, 100km / h, 110km / h, and the calculation results are as follows when crossing straight ahead:

[0097] Table 2 Comparison of calculation results of straight crossings under different speed conditions

[0098]

[0099] It can be seen from the calculation results that all indicators increase to varying degrees with the increase of driving speed. The specific situation is as follows: Figure 23 to Figure 30 shown.

[0100] For the safety index: with the increase of driving speed, when the heavy-duty truck goes stra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com