Combined surface modeling method considering rough surface waviness and micro-bulge interaction

A rough surface, modeling method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of ignoring the interaction of asperities, increasing theoretical model and experimental data errors, etc., to achieve a good contact mechanism and the effect of closed nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] see Figure 1 to Figure 4 Shown, the present invention is a kind of joint surface modeling method that considers rough surface waviness and asperity interaction, comprises the following steps:

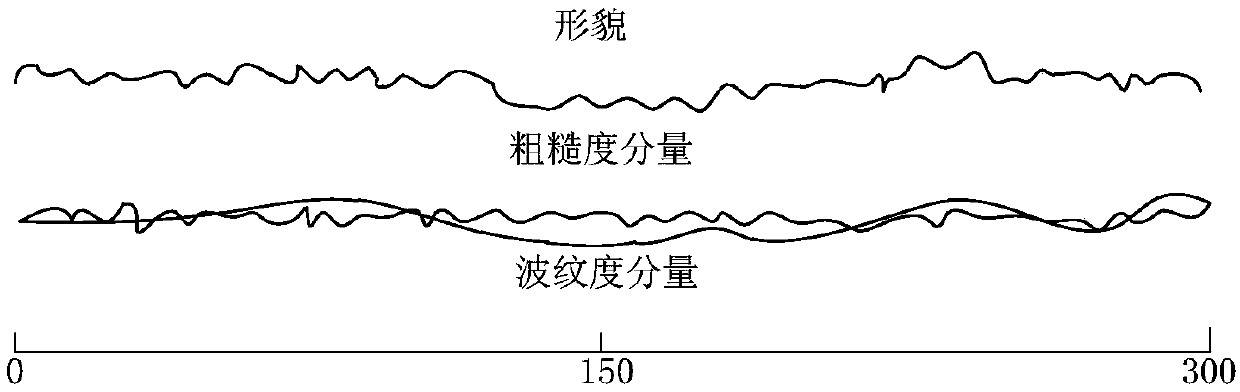

[0063] Step 1: Select multiple groups of processed mechanical parts surfaces, obtain the microscopic profile data of the measured surface through a three-dimensional shape measuring instrument, and simulate the microscopic shape of the rough surface.

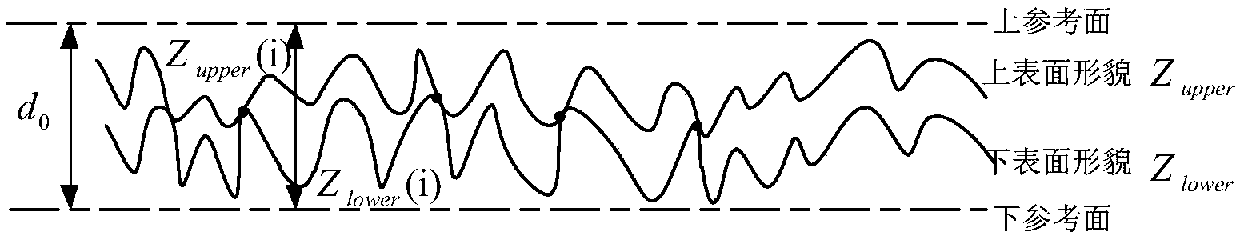

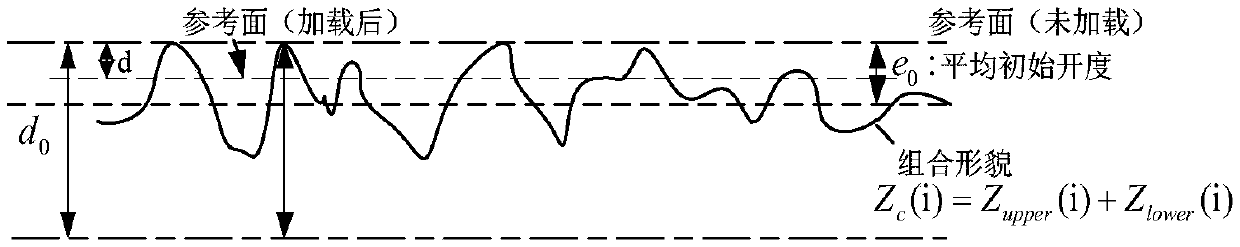

[0064] Step 2: The measured microscopic profile data of the upper and lower surfaces are regarded as independent random variables, and the top and bottom surface corresponding point topography measurement data are added to obtain the combined topography data of the joint surface:

[0065] z c (i)=z 上 (i)+z 下 (i) (1)

[0066] In the formula, z c (i) represents the combined surface morphology data, z 上 (i) represents the topographic data of the upper surface, z 下 (i) represents the topography data of the lower surface.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com