Machine tool assembly error prediction and control method

An assembly error and control method technology, applied in computer-aided design, special data processing applications, instruments, etc., can solve the failure to consider the transmission of guide rail errors, lack of scientific theoretical analysis and guidance specifications, and the amount of anti-deformation control is not very good Accurate and other issues, to achieve the effect of reducing repeated scraping work, accurate and efficient guidance of machine tool assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

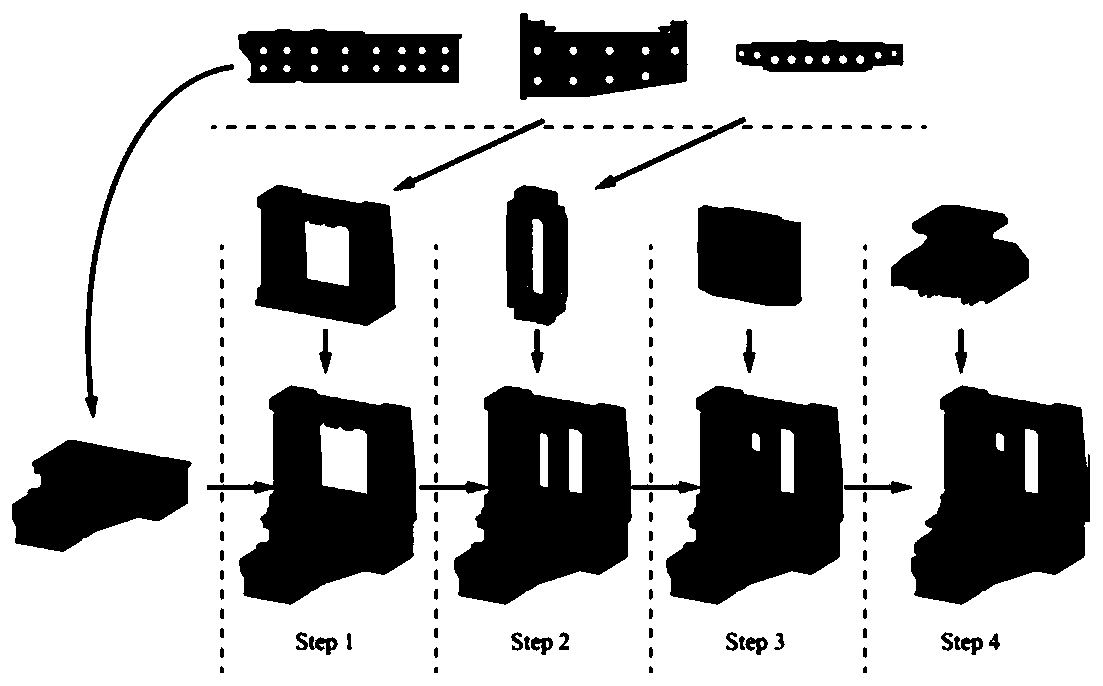

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

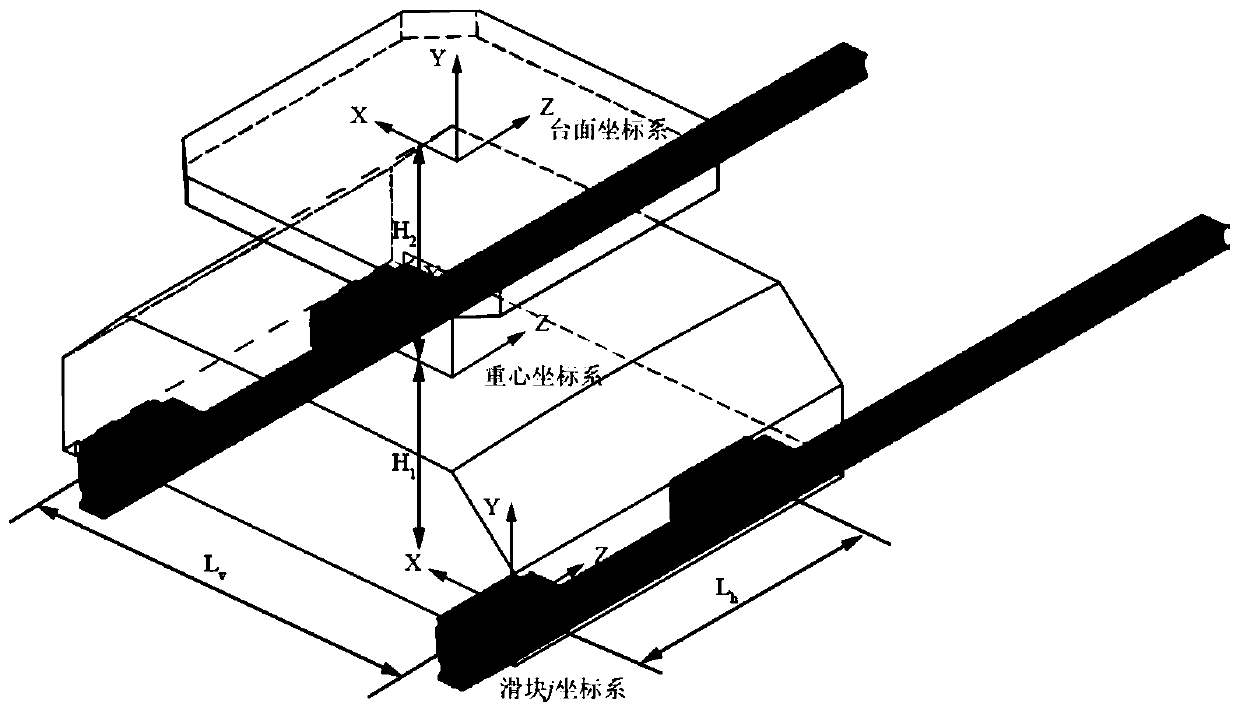

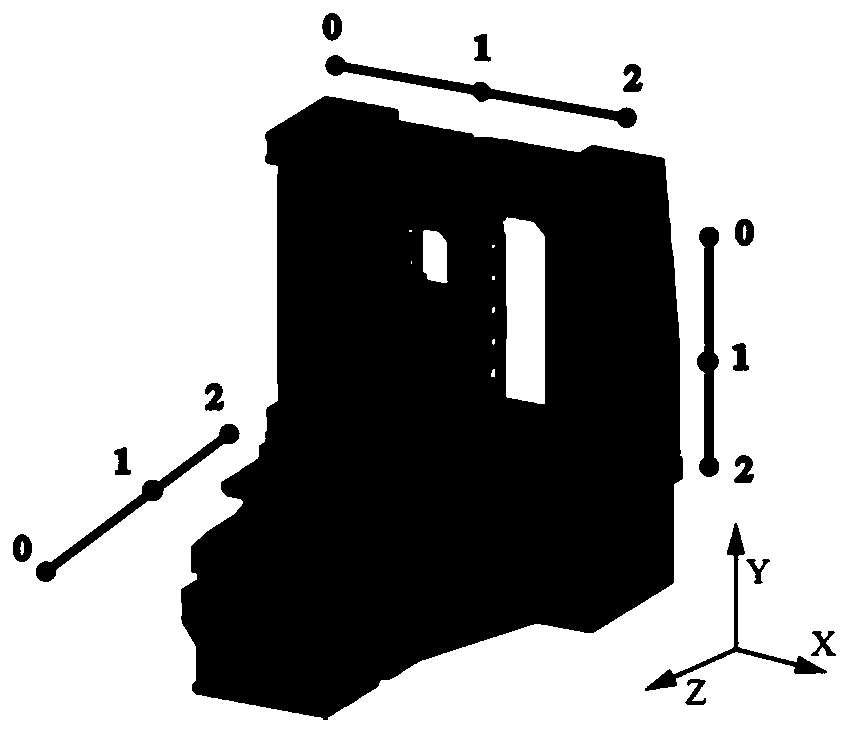

[0050] 1 Rolling guide error-worktable error transfer model establishment

[0051] 1.1 Hertz Contact Theory

[0052] According to the Hertz contact theory, the relationship between contact deformation and contact pressure is:

[0053]

[0054] In engineering applications, because the force of the roller is very complicated, its empirical formula is mainly used (reference: Zhupanska O I. Contact problem for elastic spheres: Applicability of the Hertz theory to non-small contact areas[J].International Journal of Engineering Science, 2011, 49(7):576-588.):

[0055]

[0056] Among them, E 1 ,E 2is the modulus of elasticity of the roller and the raceway surface; υ 1 , υ 2 Is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com