Method for analyzing limit pretension force of angular contact ball bearing under fixed-position pretension of high-speed electric spindle

A technology of angular contact ball bearings and high-speed electric spindles, which is applied in the field of bearing preloading, and can solve problems such as the actual situation error of limit preloading force and inaccurate models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

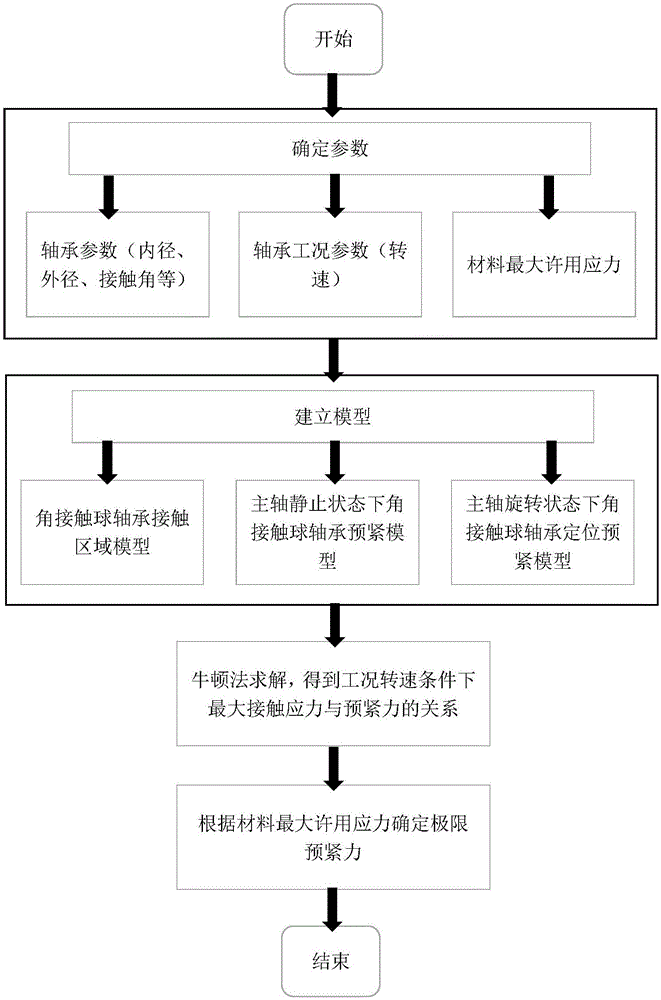

[0132] First of all, determine the bearing parameters such as the model of the bearing, the working conditions and the maximum allowable stress of the material.

[0133] In this paper, Si 3 N 4 Ceramic ball bearings as an example, Si 3 N 4 The parameters of ceramic ball bearings are shown in the table below. 3 N 4 The maximum allowable stress [σ] of ceramic materials is 2000MPa.

[0134]

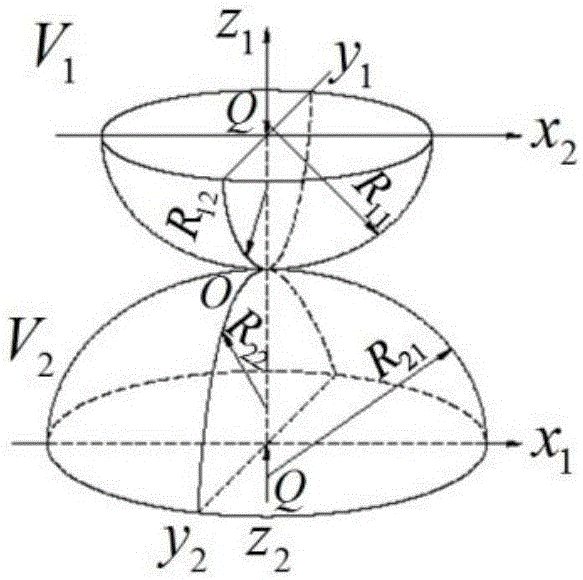

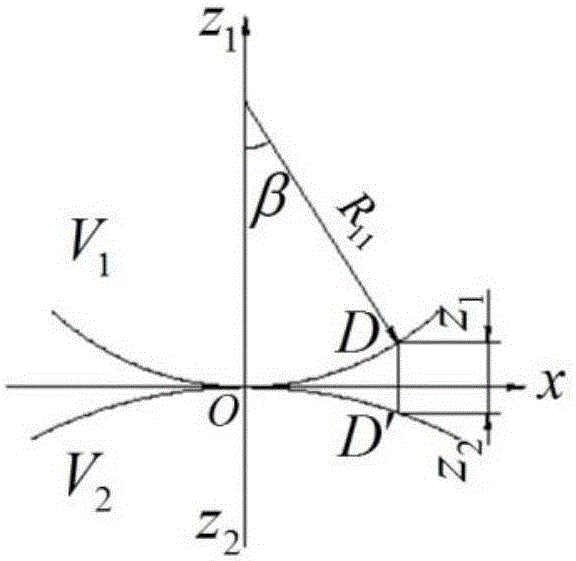

[0135] Secondly, according to the above theory, the dynamic model of angular contact ball bearing under positioning preload is established, including: angular contact ball bearing contact area model, angular contact ball bearing preload model under spindle static state, angular contact ball bearing positioning preload under spindle rotating state Model.

[0136] Get the ellipticity parametric equation f 1 ,f 2 :

[0137] f 1 = 2 ( 1 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com