Blasting lumpiness measuring method based on photogrammetry and particle contact theory

A technology of photogrammetry and measurement method, applied in measurement devices, instruments, scientific instruments, etc., can solve the problem of not being able to well reflect the distribution law of the size of the blast pile, a single evaluation index for the size of the blast pile, and the limited application scope of the site. To ensure accuracy and on-site measurement efficiency, fast measurement operation, and reduce cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the blasting lumpiness measurement method based on photogrammetry and particle contact theory involved in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030]

[0031] In this embodiment, the excavation of a stockyard is taken as an example for illustration. This blasting has a total length of about 100m 2 The ore is mined by blasting, and the ore has poor water absorption.

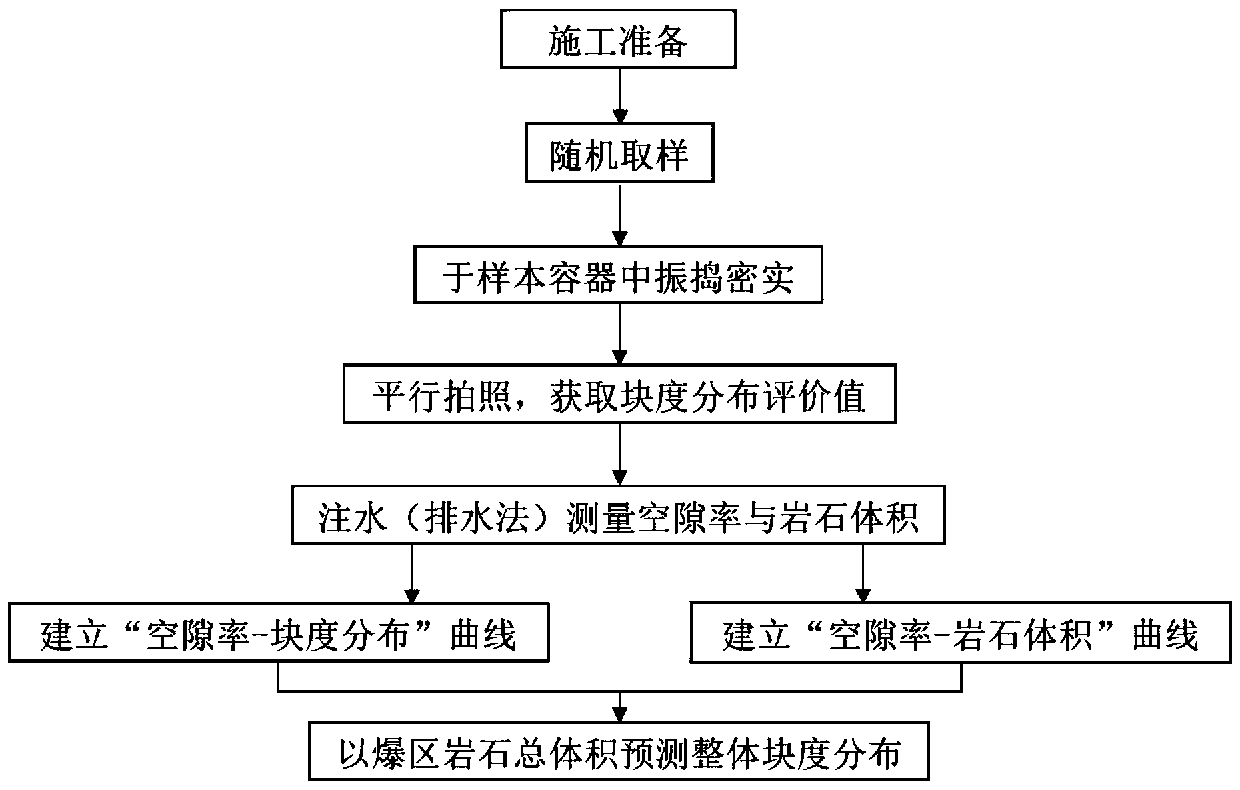

[0032] Such as figure 1 As shown, the method of blasting block size measurement based on photogrammetry and particle contact theory is used to predict the distribution of blast block size, which specifically includes the following steps:

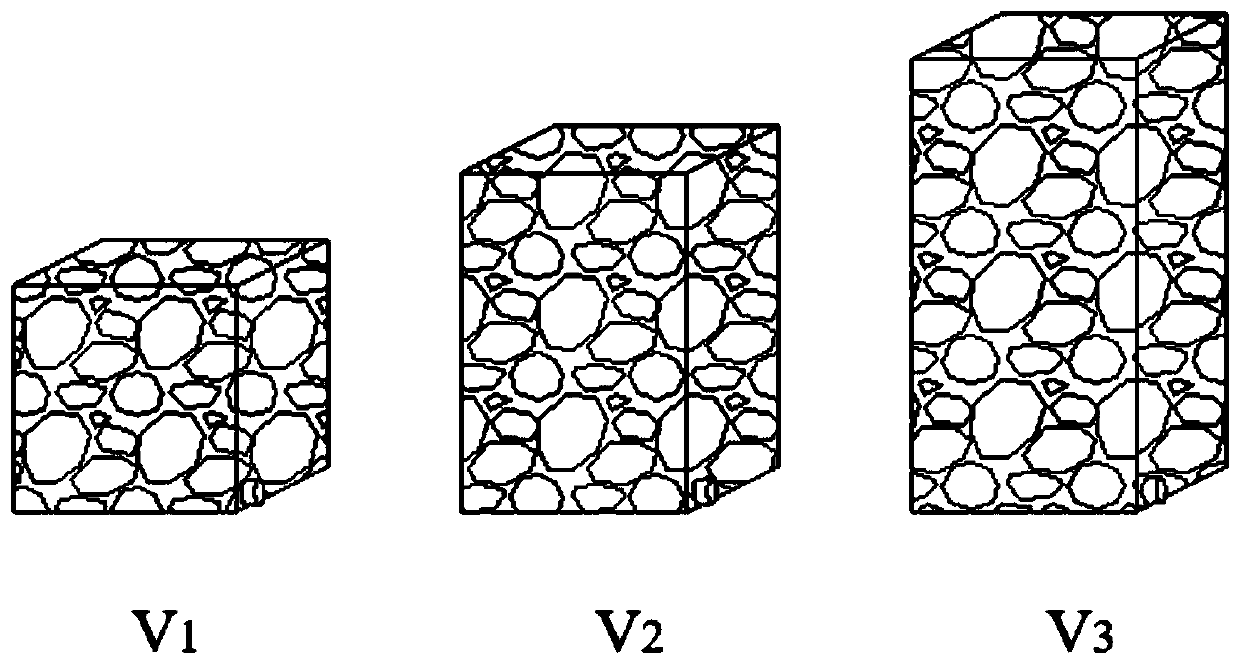

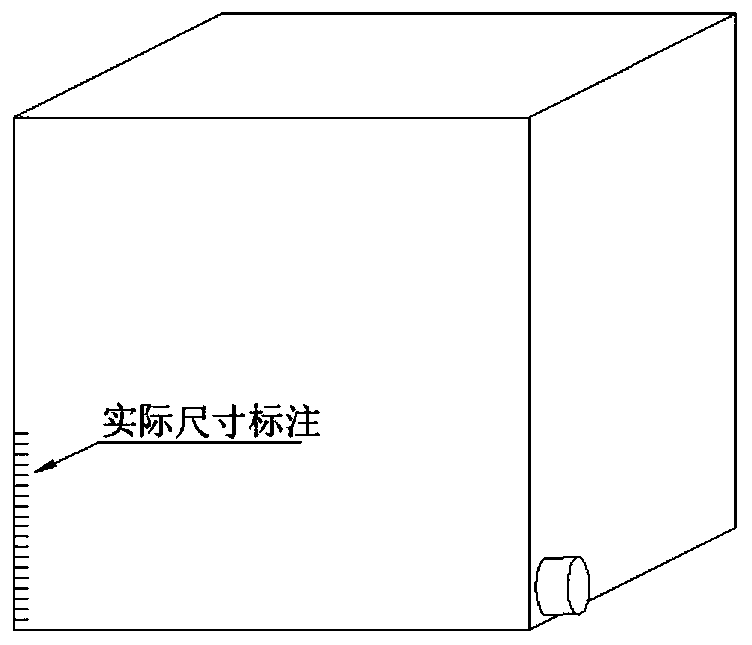

[0033] Step 1. Randomly select rock samples from the explosive pile rocks. Since at least three data points are required to draw up the curve, at least three transparent containers with different volumes but the same shape are filled. The more samples, the more accurate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com