Super hard material nanometer hardness measuring method considering press head elastic deformation

A technology of elastic deformation and nano-hardness, which is applied in the direction of testing material hardness, etc., can solve the problem of not considering the hardness measurement error of the indenter, and achieve the effect of accurate hardness and simple data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

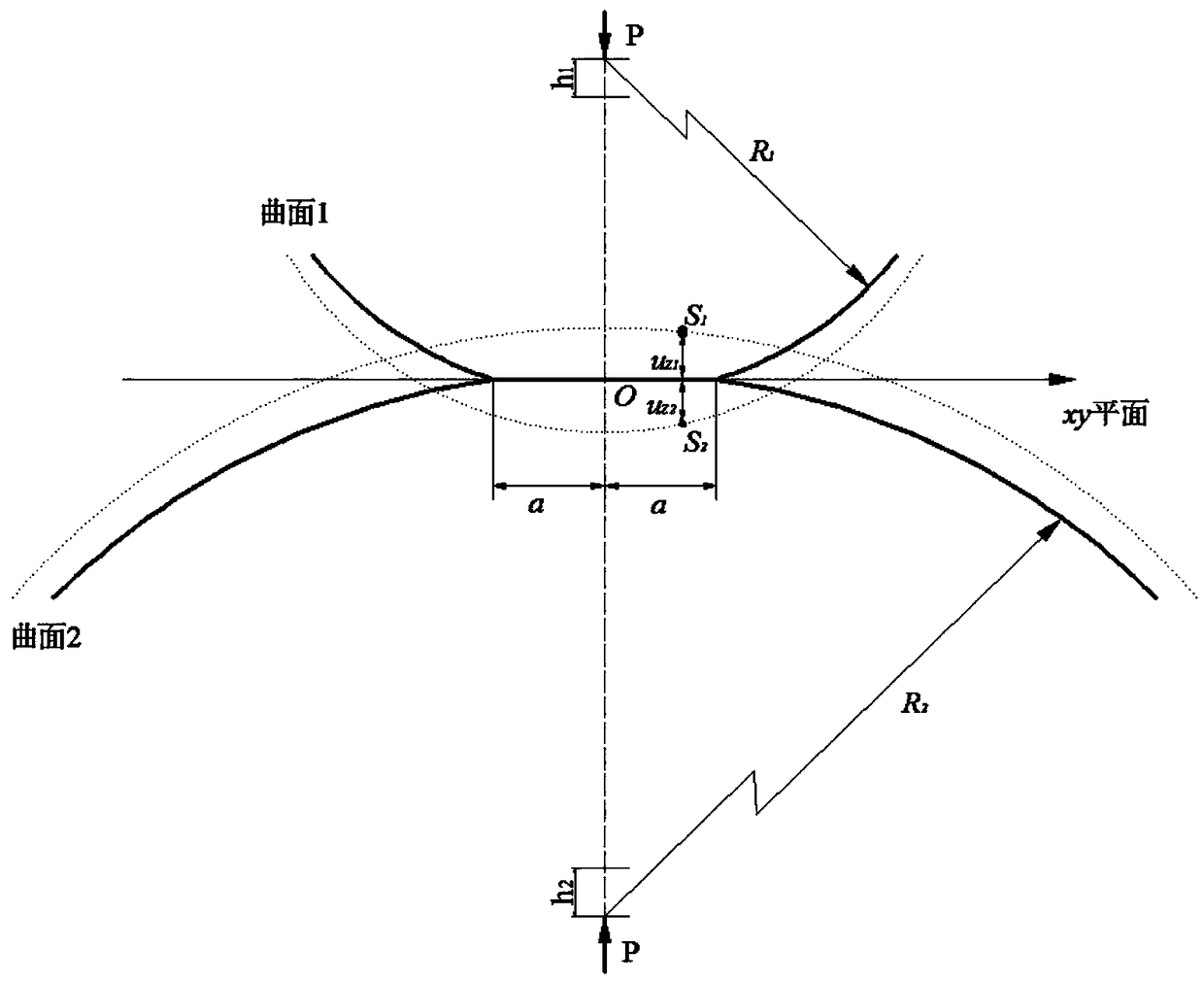

[0020] Specific implementation mode 1: This implementation mode records a method for measuring the nanohardness of superhard materials considering the elastic deformation of the indenter, and the steps of the method are as follows:

[0021] Step 1: Based on Hertz’s elastic contact theory, establish a model of elastic contact between two objects, and derive the calculation formula of hardness according to this model. Specifically, formulas 1-7 are two rigid body contacts, which can be used for calculation regardless of elastic deformation; Compared with the existing technology, this model no longer regards the indenter as a rigid body with a fixed geometry, but considers the elastic deformation of the indenter;

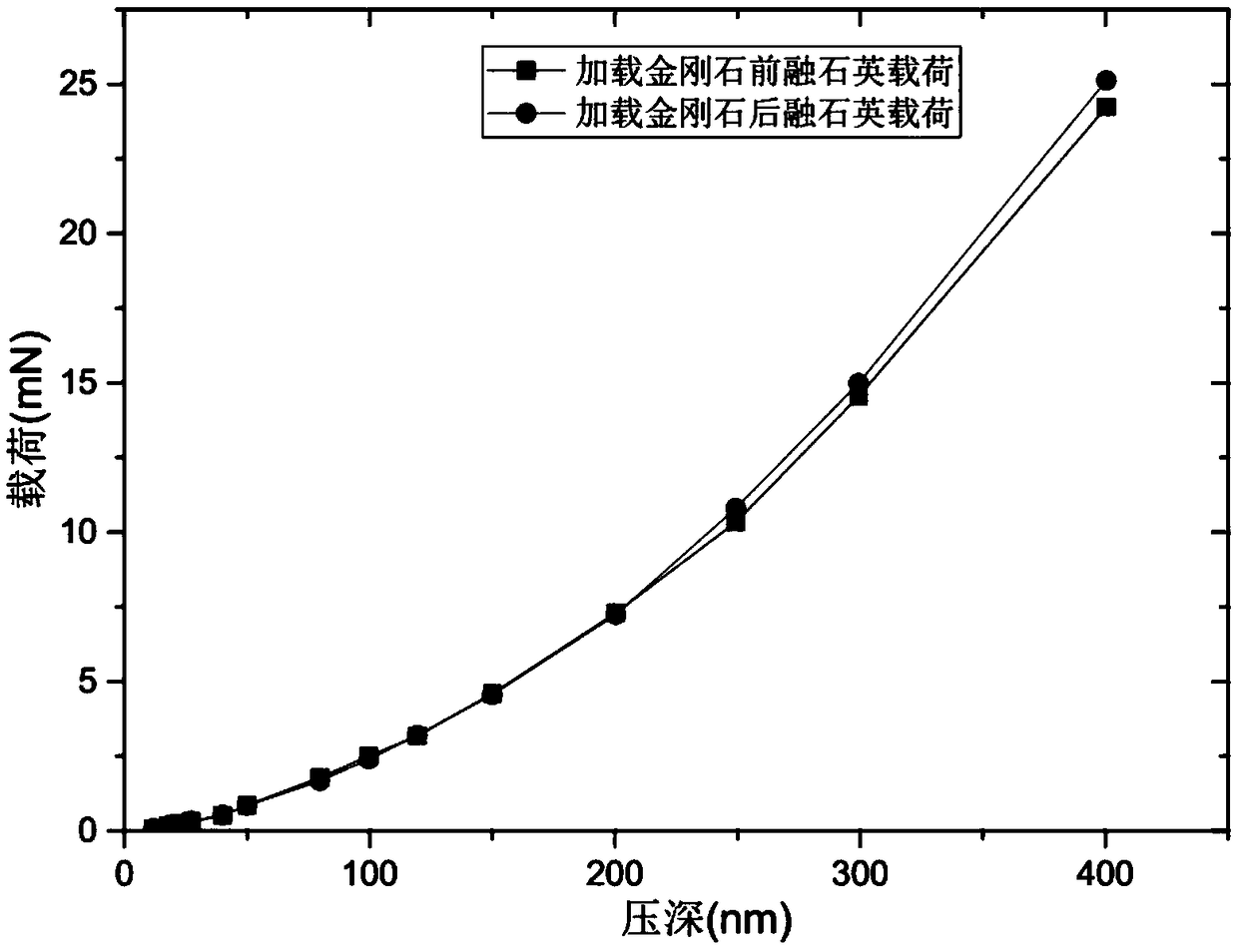

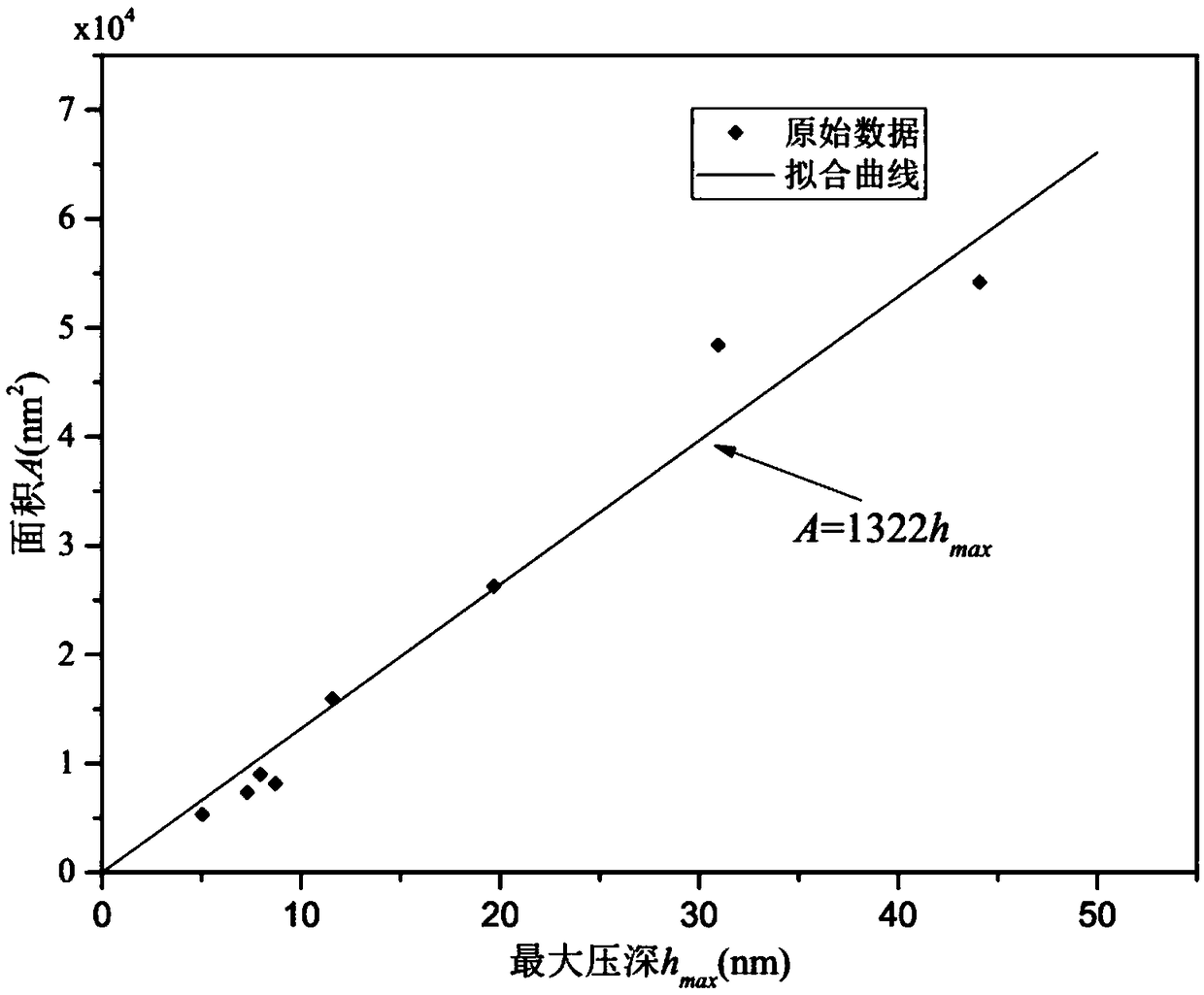

[0022] Step 2: Adopt nano-indentation test, load standard fused silica samples at different nano-indentation depths with the indenter, and calibrate the area function of the indenter according to the loading and unloading data of the fused silica samples; compared with ...

specific Embodiment approach 2

[0025] Embodiment 2: A method for measuring the nanohardness of superhard materials when considering the elastic deformation of the indenter described in Embodiment 1. In step 1, the formula for calculating the hardness is as follows:

[0026]

[0027] In the formula, P max is the maximum load, and A is the contact projected area.

specific Embodiment approach 3

[0028] Specific embodiment three: a method for measuring the nanohardness of superhard materials when considering the elastic deformation of the indenter described in the second specific embodiment, the functional expression of the contact projected area A described is as follows:

[0029] A=πRh

[0030] In the formula, R is the radius of the blunt circle at the tip of the indenter, and h is the indentation depth recorded by the nanoindenter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com