Yogurt firmness evaluation method and yogurt firmness evaluation device

An evaluation method and technology for evaluating devices, which can be applied to measuring devices, testing material hardness, dairy products, etc., and can solve problems such as labor and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

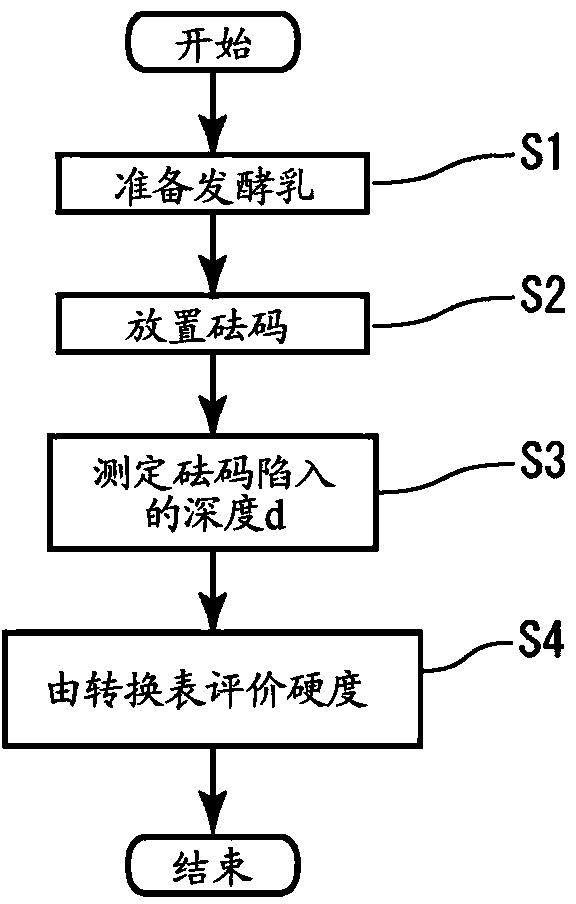

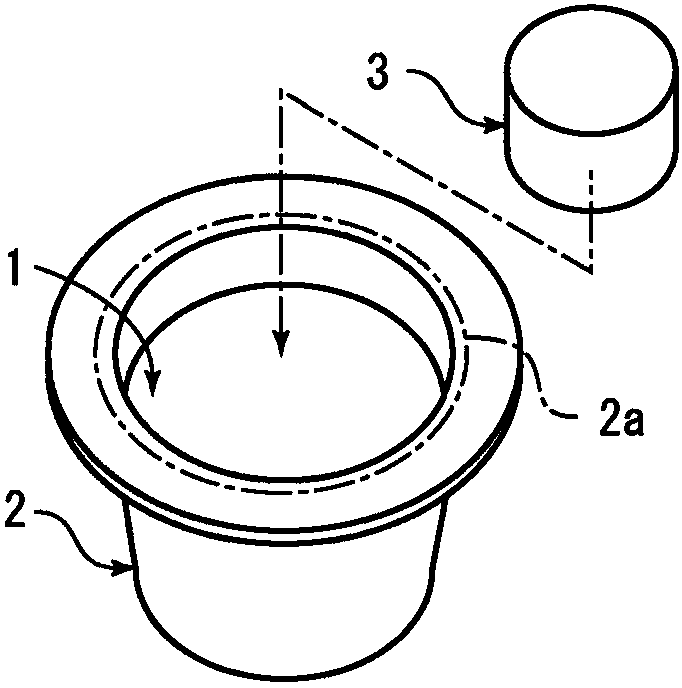

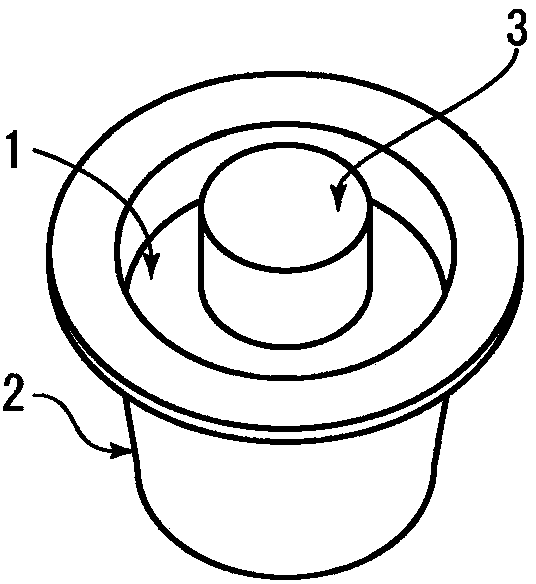

[0042] pass figure 1 The evaluation method of the hardness of the fermented milk which concerns on Embodiment 1 of this invention is demonstrated with FIG. 2. figure 1 It is a figure which shows the evaluation method procedure of the hardness of the fermented milk of this embodiment. Figure 2A ~ Figure 2D It is a figure for demonstrating the evaluation method of the hardness of the fermented milk of this embodiment, Figure 2A ~ Figure 2C is a stereogram, Figure 2D is along Figure 2C Sectional view of line A-A' in the middle.

[0043] The method for evaluating the hardness of fermented milk according to the present embodiment includes the steps of: preparing fermented milk 1, which is contained in a container 2 having an opening 2a at the top (step S1); putting a weight in through the opening 2a 3. Place weight 3 on top of fermented milk 1 (step S2); measure the depth d of weight 3 sinking into fermented milk 1 after placing weight 3 for a specified time (step S3); The...

Embodiment approach 2

[0062] Figure 4 It is a figure which shows the evaluation method procedure of the hardness of the fermented milk which concerns on Embodiment 2 of this invention. The method for evaluating the hardness of fermented milk according to the present embodiment includes the following steps: preparing fermented milk, which is placed in a container having an opening at the top (step S1); putting a weight into the opening, and placing the weight Place it on the top of the fermented milk (step S2); measure the depth d (step S3) that the weight sinks into the fermented milk after the specified time has passed since placing the weight; the depth that the weight sinks into and the reference value associated with the weight Comparison process (step S4) for comparison; evaluation of the hardness of fermented milk from the result of the comparison process and the threshold value of the hardness associated with the weight (step S5).

[0063] First, steps S1 to S3 are implemented. Steps S1 t...

Embodiment approach 3

[0071] Figure 5 It is a figure which shows the evaluation method procedure of the hardness of the fermented milk which concerns on Embodiment 3 of this invention. The method for evaluating the hardness of fermented milk according to the present embodiment includes the following steps: preparing fermented milk, which is contained in a container having an opening at the top (step S1); Place weight 1 on top of the weight (step S2); measure the depth d1 (step S3) at which weight 1 sinks into the fermented milk after a predetermined time has elapsed from the placement of weight; compare the depth d1 with the reference value associated with weight 1 Compare (step S4); take out weight 1 from the opening, put weight 2 from the opening again, and place weight 2 on the top of the fermented milk (step S2-1); measure after placing weight 2 After the specified time, the weight 2 is immersed in the depth d2 in the fermented milk (step S3-1); the depth d2 is compared with the reference val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com