Thin-wall piece milling vibration restraining method based on movable support

A milling flutter and dynamic support technology, which is applied in the direction of manufacturing tools, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of long time consumption, fast prediction of limited stable domain, large amount of experiments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

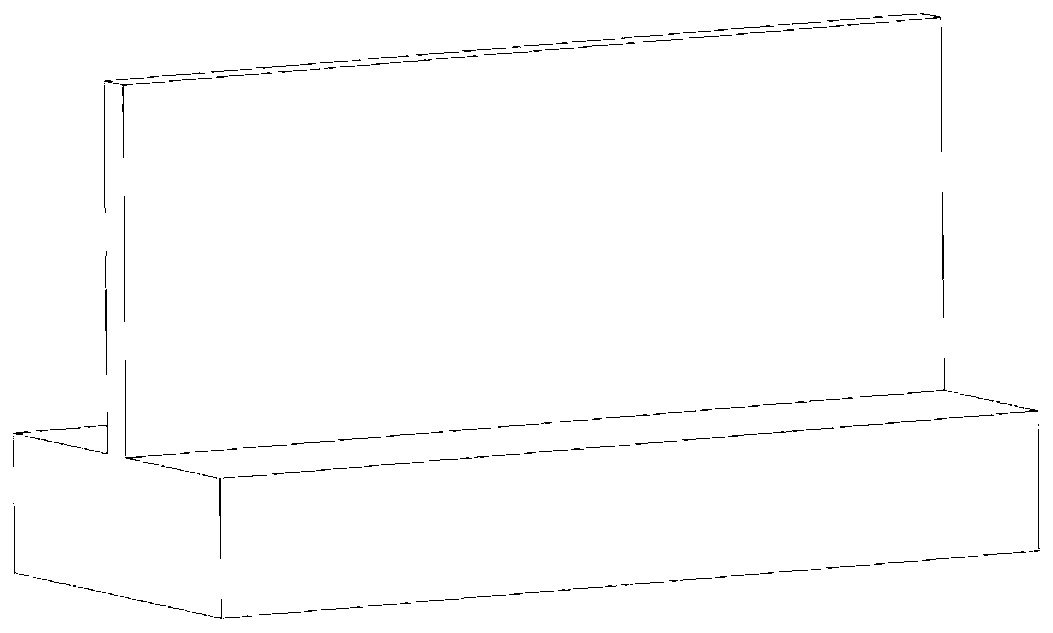

[0137] Embodiment 1: the plane straight thin plate size is 100mm × 40mm × 4mm, the material is aluminum alloy 7075, the modulus of elasticity is 71.7GPa, and the density is 2830kg / m 3 , Poisson's ratio is 0.33.

[0138] 1. According to the milling characteristics of thin-walled parts, a multi-point contact milling dynamic model considering the deformation of the tool and the workpiece is established; the contact area between the tool and the workpiece is divided into 24 microelements along the axial direction, and the milling Concentrate forces on nodes and find dynamic milling forces:

[0139]

[0140] The dynamic state equation of the milling system is:

[0141]

[0142] m W,0 ,C W,0 , K W,0 Represents the mass, damping, and stiffness matrices of the initial workpiece; and Q W (t) represents the acceleration, velocity and displacement vector of the workpiece under physical coordinates;

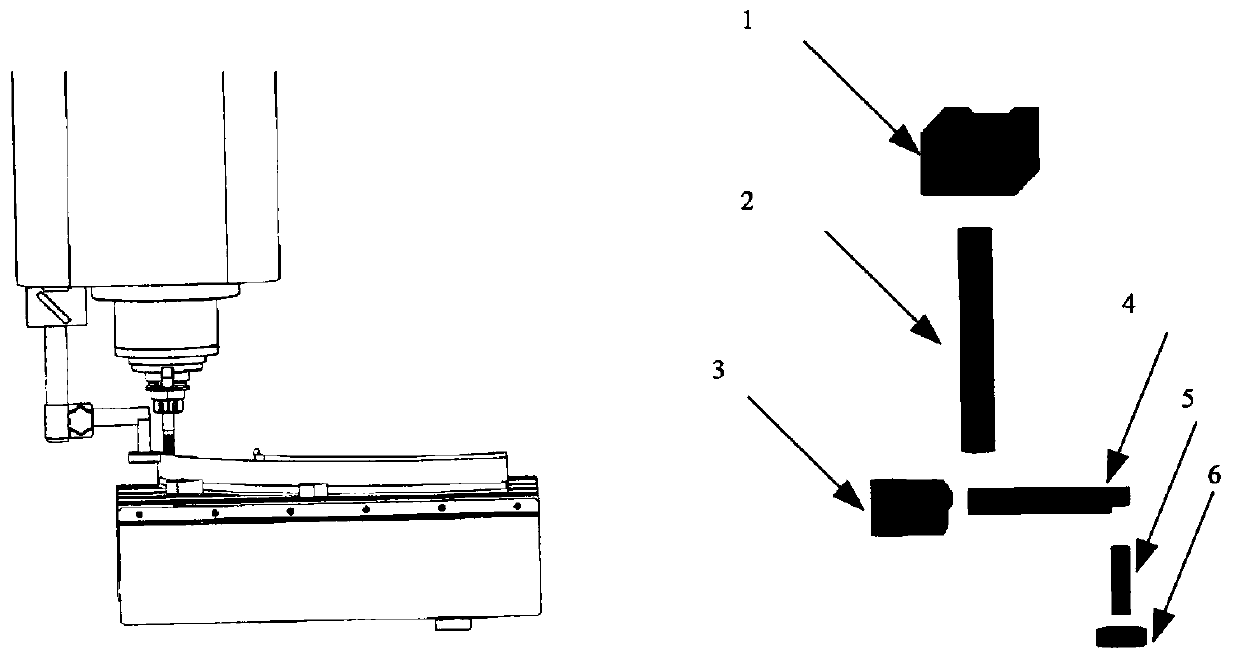

[0143] two, figure 1 Middle part 1 is a magnetic suction seat, part 2, pa...

Embodiment 2

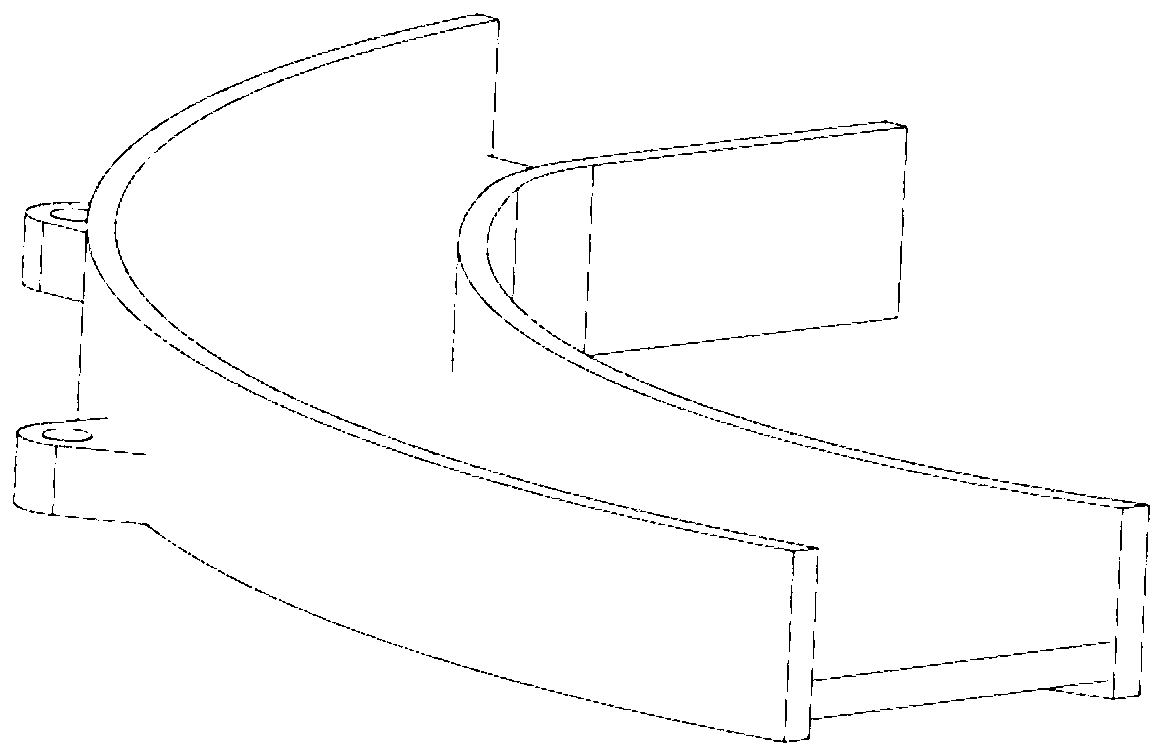

[0198] Example 2: The size of the curved thin plate is 319mm long, 39mm high, 3.6mm thick, and the radius of curvature is 178mm; the material is aluminum alloy 7075, the modulus of elasticity is 71.7GPa, and the density is 2830kg / m 3 , Poisson's ratio is 0.33.

[0199] 1. Aiming at the milling characteristics of thin-walled parts, establish a multi-point contact milling dynamics model that simultaneously considers the deformation of the tool and the workpiece; divide the contact area between the tool and the workpiece into 28 microelements along the axial direction, and divide the milling Concentrate forces on nodes and find dynamic milling forces:

[0200]

[0201] The dynamic state equation of the milling system is:

[0202]

[0203] m W,0 ,C W,0 ,K W,0 Represents the mass, damping, and stiffness matrices of the initial workpiece; and Q W (t) represents the acceleration, velocity and displacement vector of the workpiece under physical coordinates;

[0204] two, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com