Nanoindentation testing method for elastic moduli of austenite phase and martensite phase of shape memory alloy

A technology of elastic modulus and memory alloy, applied in the direction of testing the hardness of materials, etc., can solve the problems that cannot be used as mechanical parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below by means of the accompanying drawings and examples.

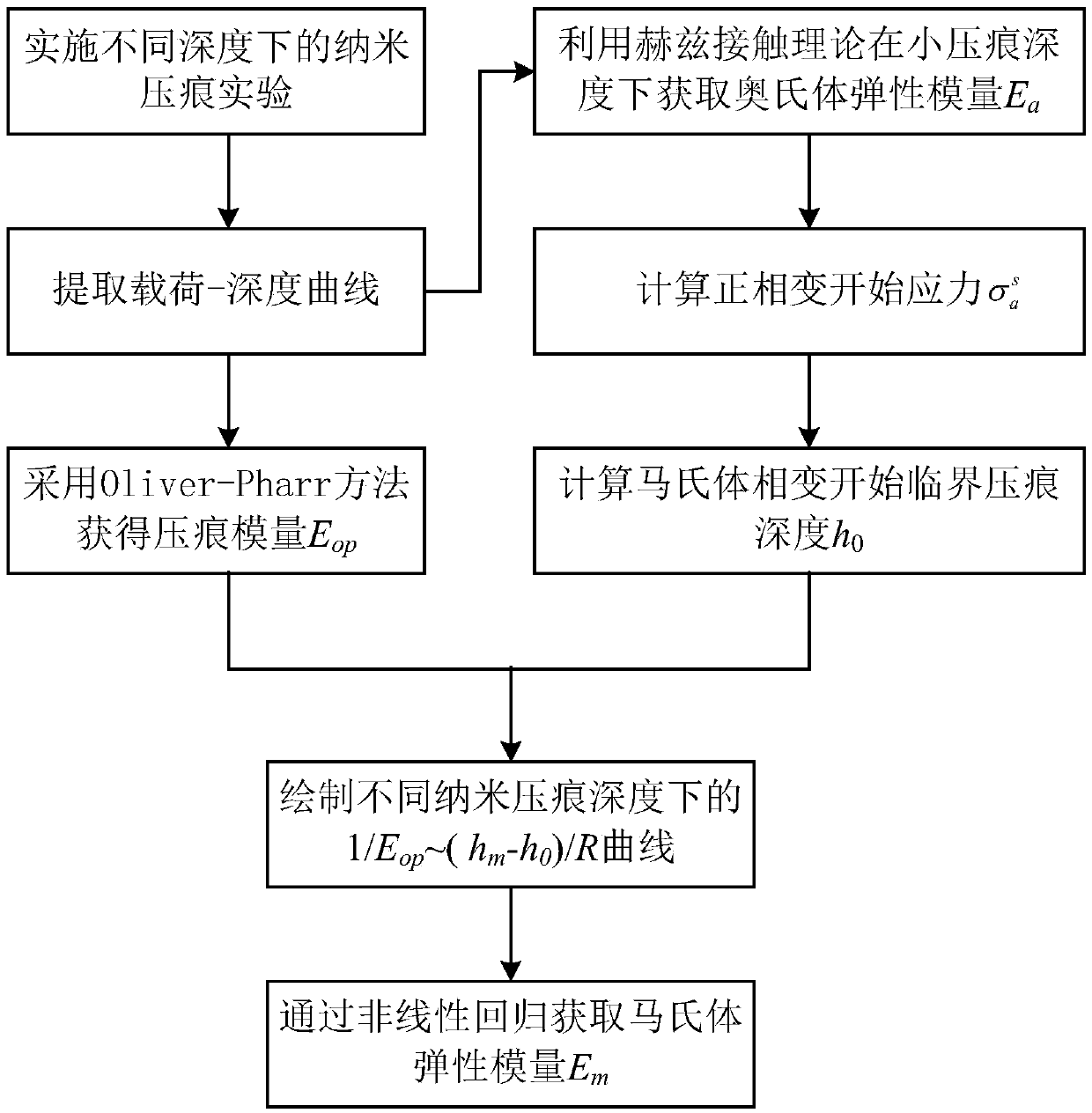

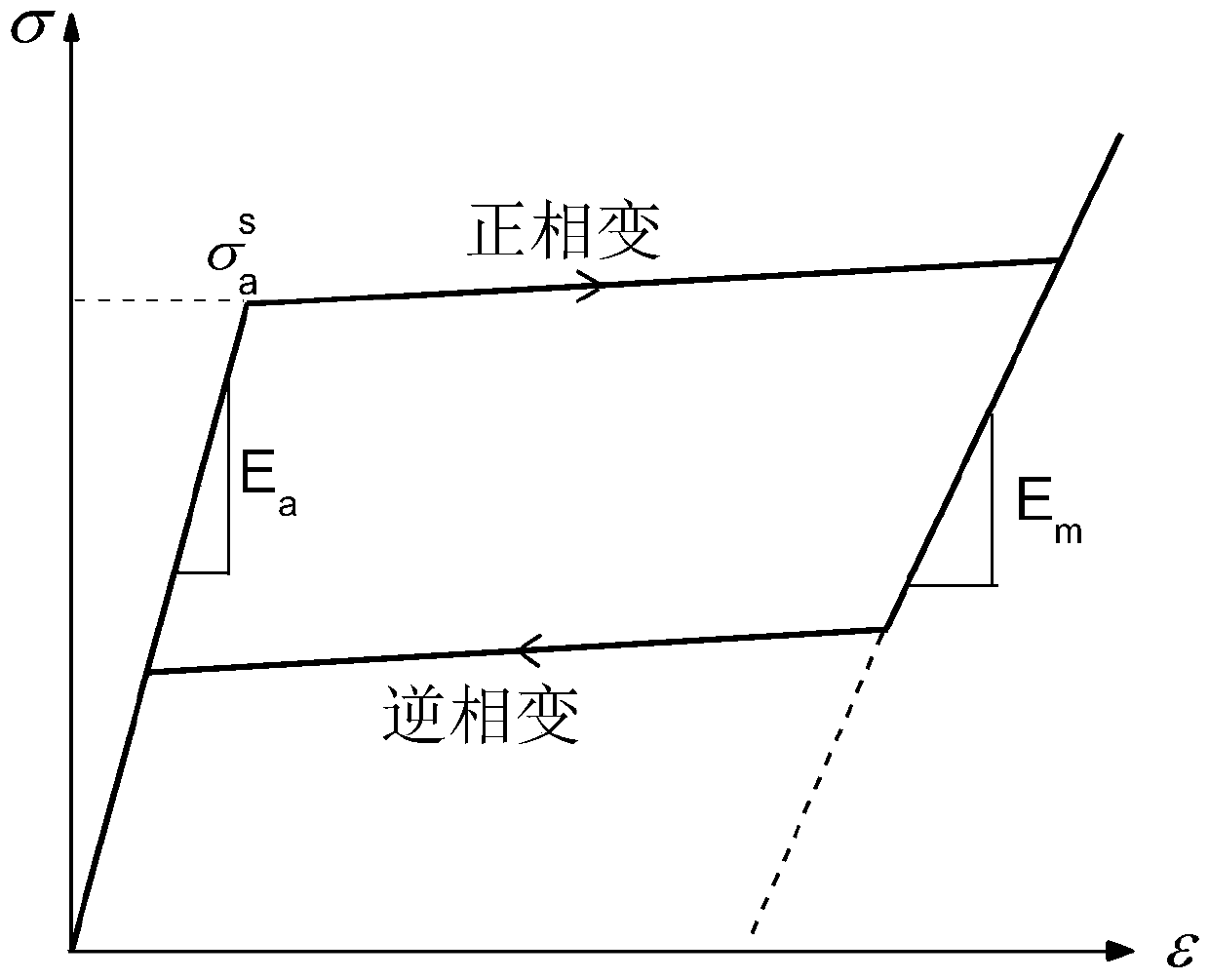

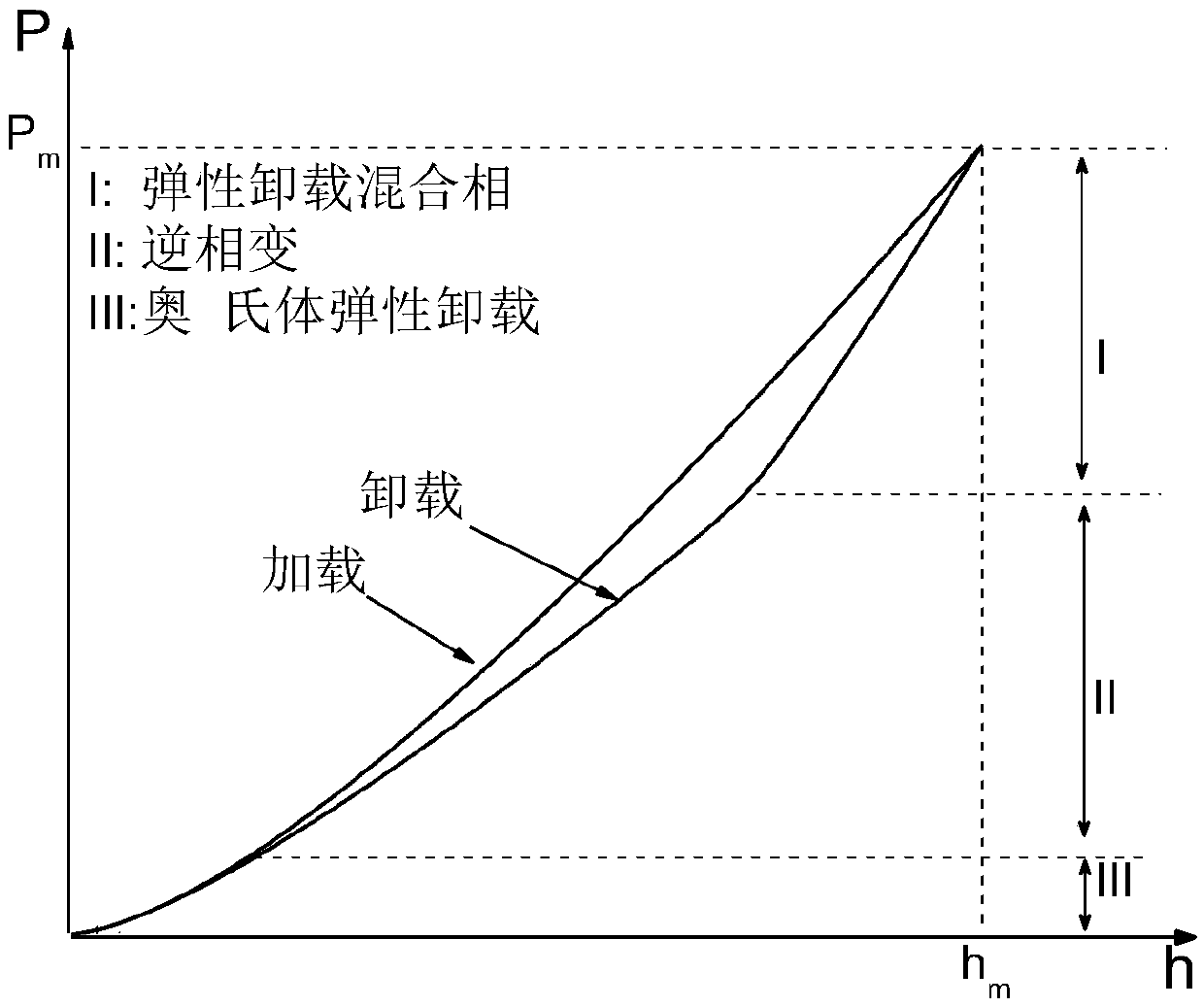

[0030] figure 1 shows the flow of a nanoindentation measurement method for the austenite and martensite elastic moduli of shape memory alloys, the austenite elastic modulus E a and the martensitic modulus of elasticity E m For the definition on the stress σ-strain ε curve, see figure 2 .

[0031] It should be pointed out that the nanoindentation experiments involved in the present invention all use spherical indenters.

[0032] The specific implementation method is described as follows:

[0033] Step 1. Carry out a small depth indentation experiment, requiring h m / R≤0.001, calculate the austenite elastic modulus E by formula 1 a ;

[0034] P m = 4 E a h m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com