Measuring method for limiting shearing stress of nanometer material

A technology of shear stress and nano-materials, applied in the direction of applying stable shear force to test the strength of materials, etc., can solve the problem of low precision, achieve the effect of high quantitative measurement precision, low requirements, and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

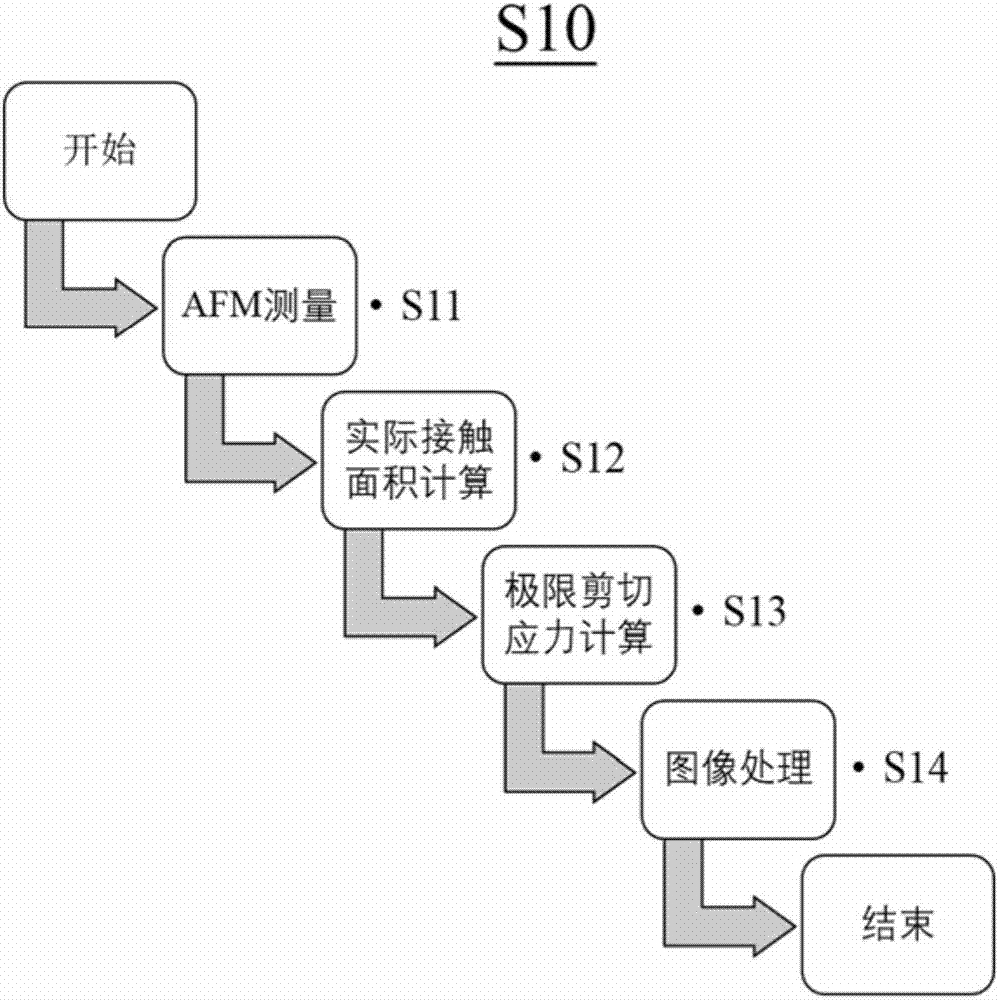

Method used

Image

Examples

Embodiment 1

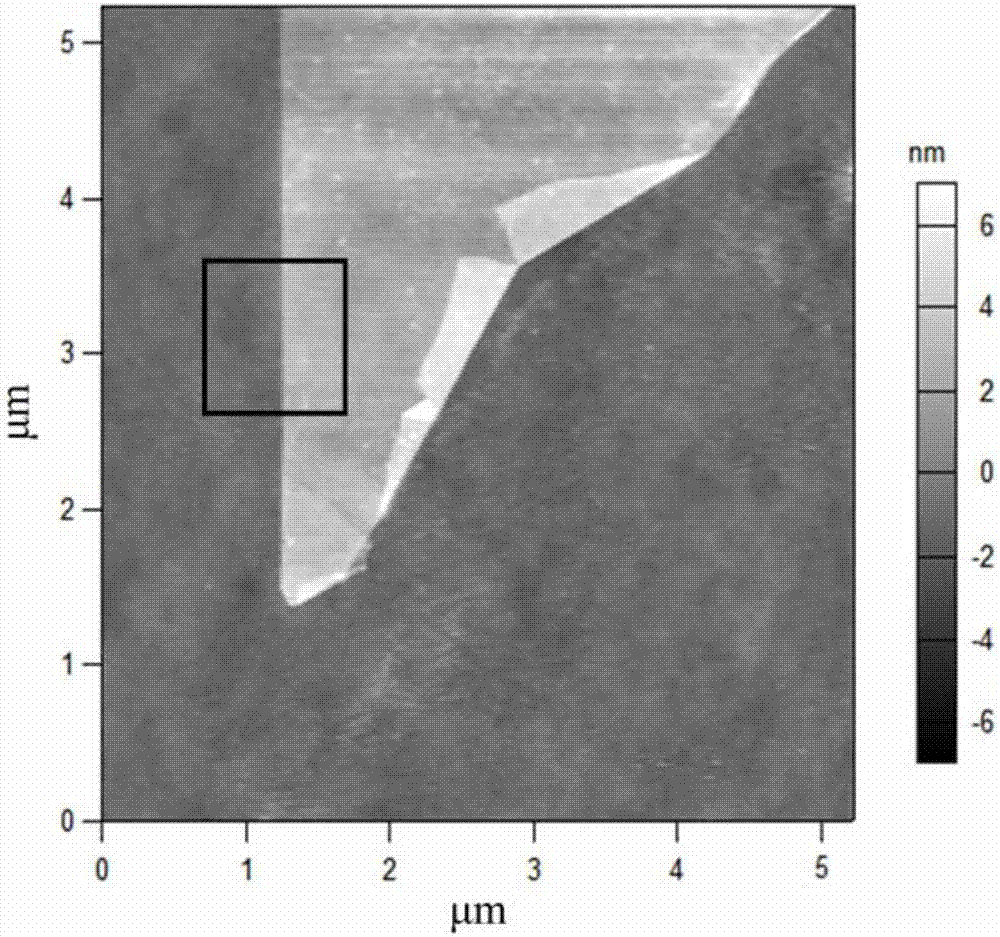

[0049] The AFM model used in Example 1 is: Cypher ES, Asylum Research, CA; the probe model used for friction measurement is: AC240TS, Olympus, with a radius of about 9nm, an elastic modulus of 190GPa, and a friction calibration coefficient of 566.33nN / V; the sample to be tested is graphene prepared by mechanical exfoliation method, and the elastic modulus is 1000GPa. figure 2 is the AFM surface topography image of the graphene. The entire nanomaterial ultimate shear stress measurement experiment process is completed in a clean room with a temperature of 23°C and a humidity of 50%.

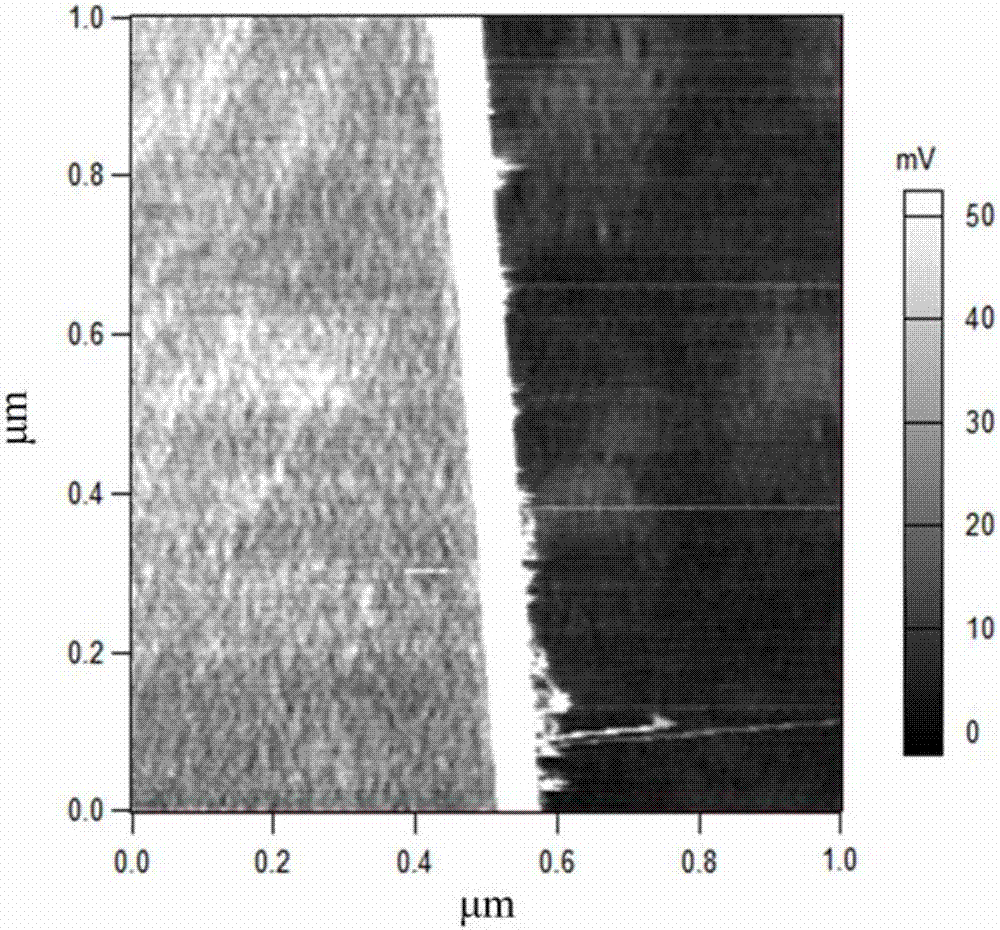

[0050] According to step S11, using the lateral force module of the AFM to measure figure 2 The area where the middle black box is located is in F n = Triboelectric signal under load of 99.31nN, the triboelectric signal image scanned by it is as follows image 3 As shown, the left half of the figure is the friction image of the silicon substrate, and the right half of the area is the friction ...

Embodiment 2

[0054] The AFM model used in Example 2 is: Cypher ES, Asylum Research, CA; the probe model used for friction measurement is: AC240TS, Olympus, with a radius of about 9nm, an elastic modulus of 190GPa, and a friction calibration coefficient of 566.33nN / V; the sample to be tested is MoS 2 Nanosheets with an elastic modulus of 270GPa. Figure 5 for the MoS 2 AFM surface topography images of nanosheets. The entire nanomaterial ultimate shear stress measurement experiment process is completed in a clean room with a temperature of 23°C and a humidity of 50%.

[0055] According to step S11, using the lateral force module of the AFM to measure Figure 5 The triboelectric signal of the area where the middle black box is located under a load of 9.93nN, the scanned triboelectric signal image is as follows Figure 6 As shown, the upper left triangular area in the figure is the friction image of the silicon substrate, and the lower right triangular area is the MoS 2 Tribological image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com