Force-position mixing control method for grinding and polishing of force-controlled robot

A hybrid control and robot technology, applied in the field of grinding and polishing, can solve the problems of not considering the influence of grinding and polishing pressure and feed speed, and achieve the effect of improving grinding and polishing precision and surface uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the following embodiments are intended to facilitate understanding of the present invention, but do not limit it in any way.

[0041] This embodiment is based on UG and robotstudio to realize an ABB force-controlled robot grinding and polishing automobile hub force-position hybrid control off-line programming method, which specifically includes the following steps:

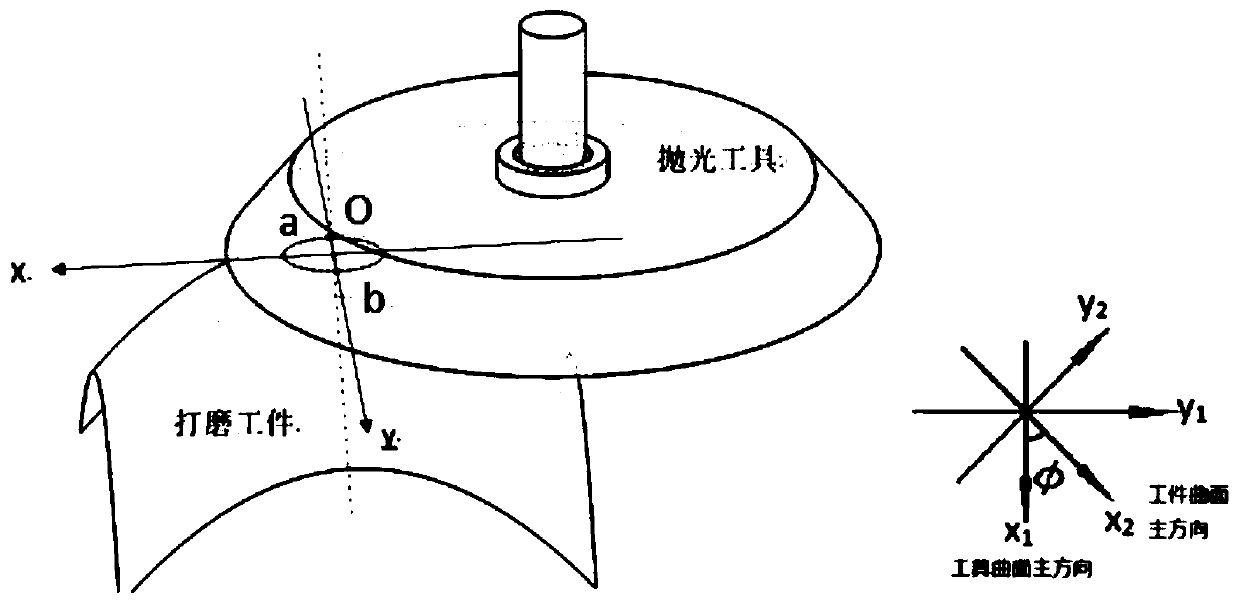

[0042] 1. Tool processing trajectory planning

[0043] First, import the three-dimensional model of the automobile wheel hub into UG, generate the corresponding tool machining track for the upper surface of the automobile wheel hub and the side of the spoke, and generate the five-axis machining G code program through the post-processor of the five-axis CNC machine tool;

[0044] 2. Robot position program generation

[0045] Using the ABB robot offline pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com