Wire rope lay pitch on-line detection device and method

A detection device and a technology for steel wire ropes, which are applied to measurement devices, electrical devices, instruments, etc., can solve the problems of inability to realize non-contact real-time detection of wire rope lay lengths, and inability to meet torsional stress analysis, and achieve real-time detection and portability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods, Structure, characteristic and effect thereof are as follows in detail.

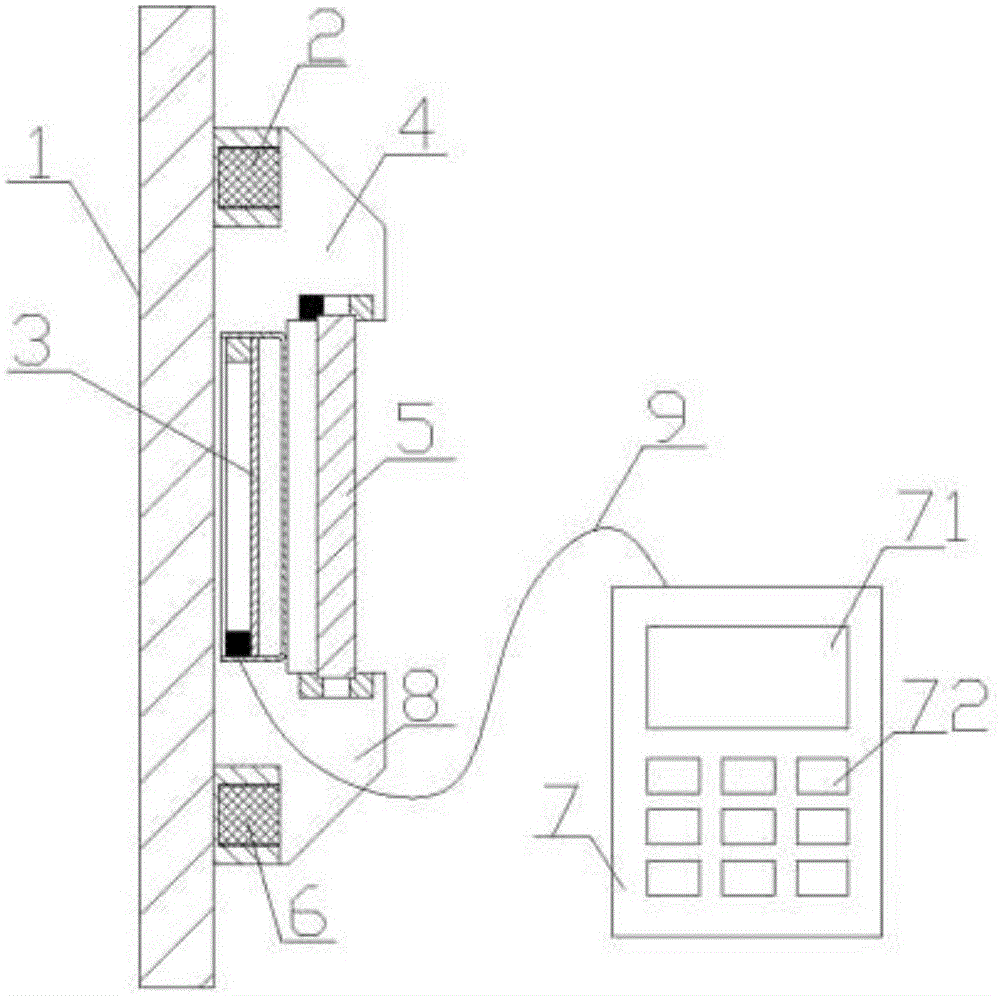

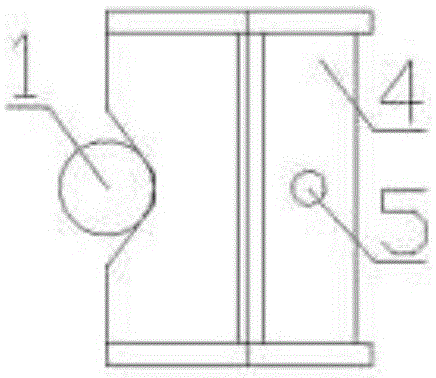

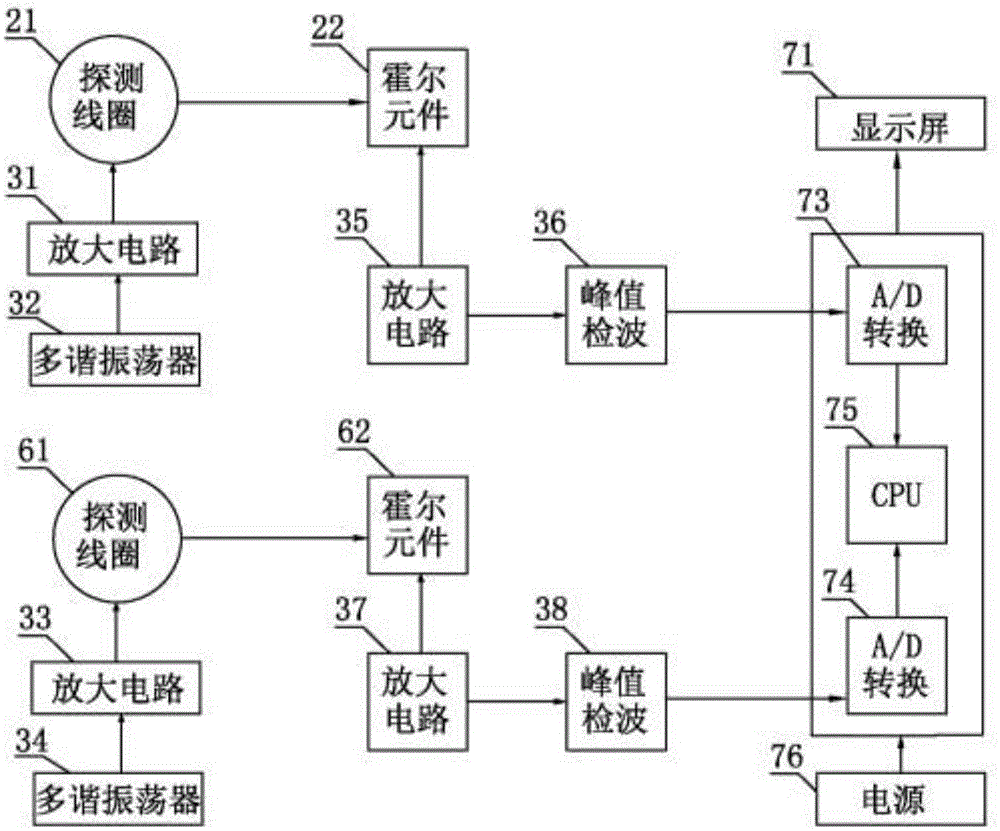

[0042] see Figure 1 to Figure 3 As shown, a kind of steel wire rope lay length online detection device of the present invention, it comprises: steel wire rope lay length detection sensor 8, data collector 7; Described steel wire rope lay length detection sensor 8 comprises eddy current displacement sensor, signal conditioning circuit board 3, housing 4. The handle 5, wherein the eddy current displacement sensor has two ends respectively located in the housing 4, which are called the upper eddy current displacement sensor 2 and the lower eddy current displacement sensor 6, and the signal conditioning circuit board 3 is in the housing 4 In the middle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com