Non-contact dynamic measurement system for torque of rotating shaft based on optical fibers

A technology of dynamic measurement and rotating shaft, applied in the direction of torque measurement, measuring device, power measurement, etc., can solve the problems of inappropriateness and achieve the effect of good stability, simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

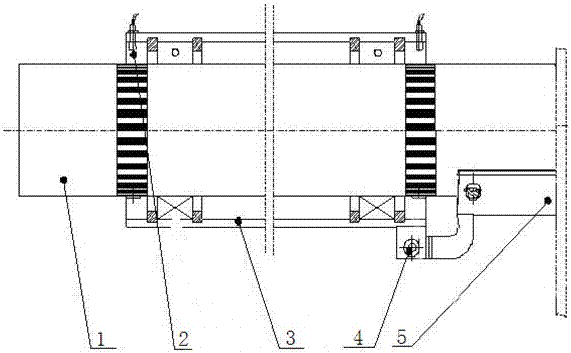

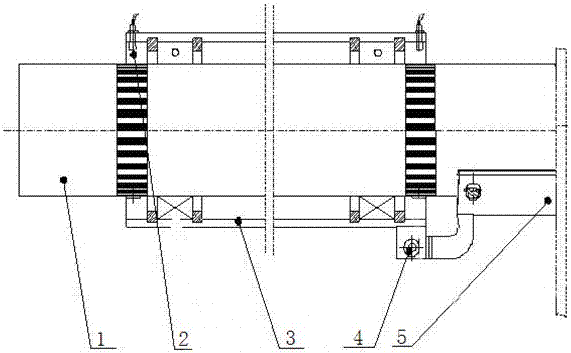

[0008] like figure 1 As shown in the figure, the measured object is the spline rotating shaft 1. At the position where the spline rotating shaft 1 is separated by a length of L, a machining center is used to engrave 30 equally divided two-row color marks on the spline shaft. A sensor positioning sleeve 3 is placed on the periphery, and three laser fiber probes 2 are installed on the sleeve relative to the two rows of stripe color marks. The three fiber probes are arranged at 120°. The positioning sleeve 3 is firmly fixed on the connecting assembly 5 by the bolted connecting assembly 4, so that when the spline rotating shaft 1 rotates, each fiber probe 2 and the strip color code maintain a relative safe distance. As the spline rotating shaft 1 rotates under different working conditions, the spline rotating shaft 1 produces corresponding angular deformation under different loads. The state is accurately measured by each group of fibers. The phase difference measured by each gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com