Piezoresistive high-frequency high-temperature dynamic pressure sensor

A dynamic pressure and sensor technology, applied in semiconductor/solid-state device components, piezoelectric/electrostrictive/magnetostrictive devices, instruments, etc. Solve problems such as strong light interference, meet the requirements of the test environment, and reduce the effect of infrared light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

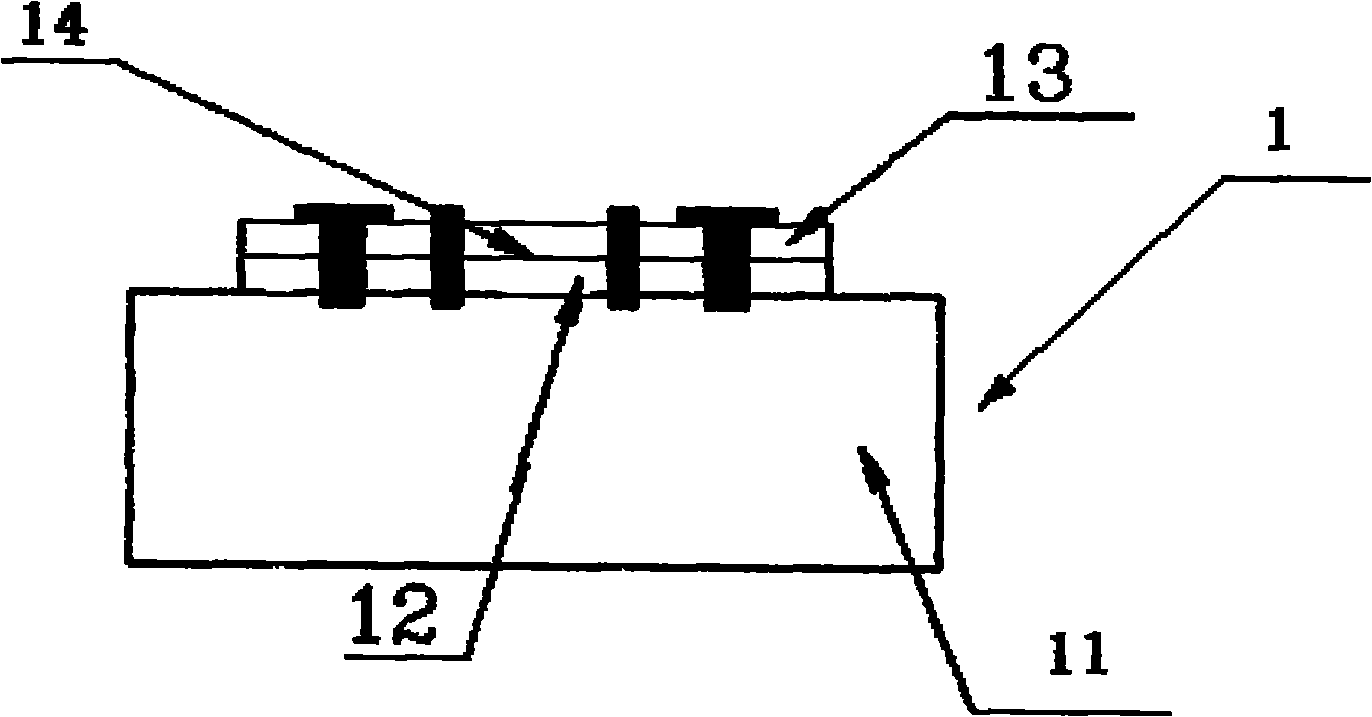

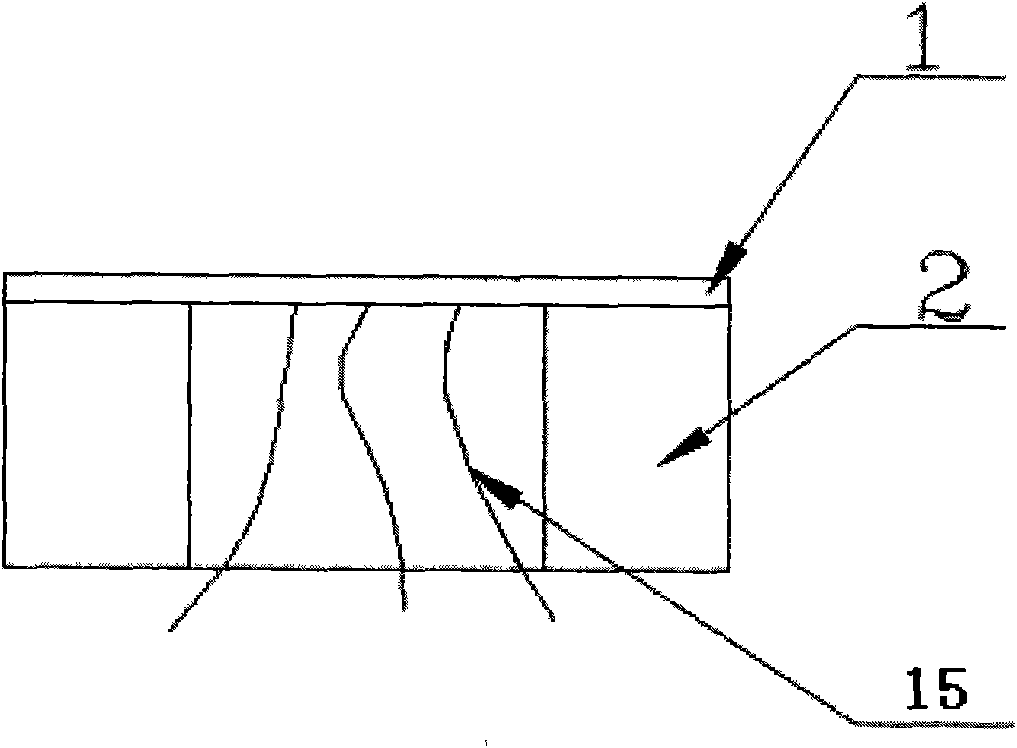

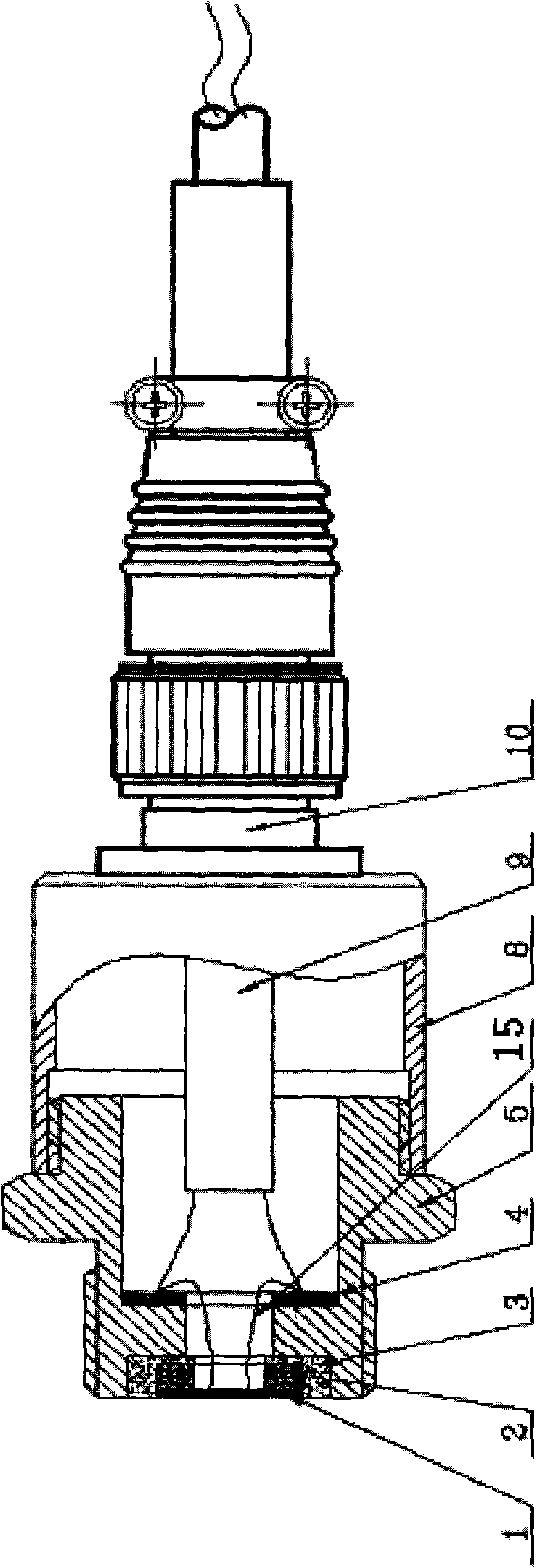

[0031] The piezoresistive high-frequency high-temperature dynamic pressure sensor adopts the round flat silicon diaphragm fixed and supported by the MEMS silicon micromachining technology, and uses the flush packaging technology to eliminate the influence of the lumen effect on the dynamic test and realize the dynamic high-temperature pressure. Real-time measurement, using high-frequency broadband amplifiers to ensure sufficient high-frequency while avoiding its weakness of small signal noise. The following implementation steps are as follows Figure 1 to Figure 5 Shown in detail:

[0032] figure 1 As shown, the circular flat silicon diaphragm 11 adopts a double-sided polished SOI silicon wafer (gold diffusion is also added in the processing of the SOI silicon wafer to increase the recombination center of the silicon wafer and reduce the lifespan of photogenerated carriers), as the elastic element , In the MEMS technology processing, the traditional thermal oxidation technol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com