Non-contact dynamic detection device and detection method for tire tread defects

A dynamic detection, non-contact technology, applied in the direction of wheel rim measurement/measurement, optical test defect/defect, etc., can solve the problems of human measurement error and low measurement efficiency, reduce human error, improve use efficiency, and avoid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

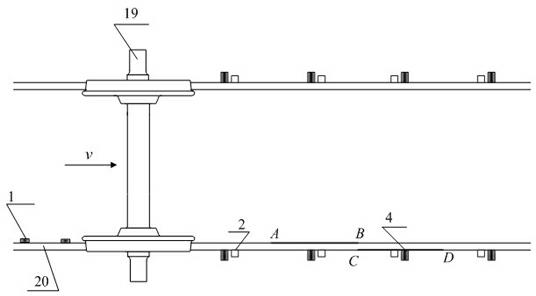

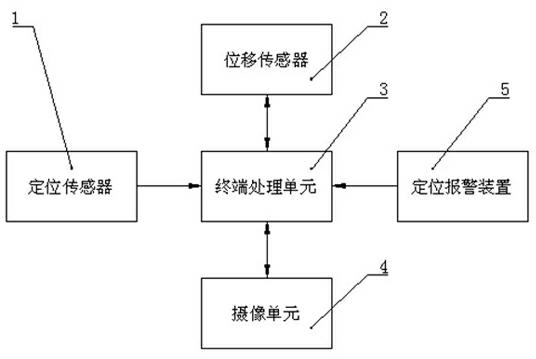

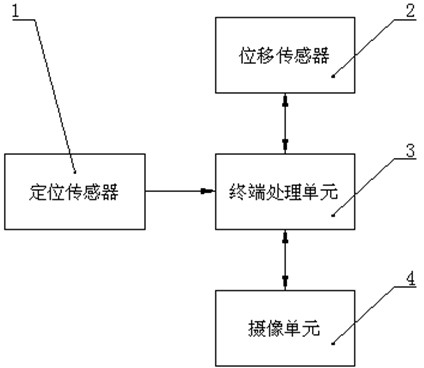

[0035] Embodiment 1: as figure 1 and figure 2 As shown, the present invention includes a terminal processing unit 3, and also includes a positioning sensor 1 arranged on one side of the rail. 4 connected. When the train is running, the rails are arranged in pairs, and the positioning sensor 1 is arranged on one side of the rail. 2 and camera unit 4 mean that the outer surfaces of the two rails 20 are provided with displacement sensors 2 and camera units 4 , and for any one of the rails, the displacement sensor 2 and camera unit 4 are located on one side of the rail 20 .

[0036] The positioning sensor 1 is two eddy current sensors or two photoelectric switches, and the displacement sensor 2 is a laser displacement sensor. The speed of the train is detected by the positioning sensor 1, the position of the tread defect on the tread circumference is judged by the displacement sensor 2 according to the scattered light signal of the wheel tread, the image of the defect is captu...

Embodiment 2

[0047] Embodiment 2: as image 3 As shown, the output end of the terminal processing unit is connected with a positioning alarm device, and other structures are the same as those in Embodiment 1.

[0048] The detection steps in this embodiment are as follows: Steps A, B, C, and D are the same as those in Embodiment 1. Afterwards, the terminal processing unit compares the calculated defect size with the set defect value. When the calculated defect is greater than the set defect value, The terminal processing unit sends a signal to the positioning alarm device, and the positioning alarm device records the defective wheels and sends out an alarm signal.

[0049] The positioning alarm device can record which wheel the defective wheel is on the carriage, so that the staff can quickly designate the maintenance point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com