Magnetic suspension type dynamic sheet shape testing method

A detection method and magnetic levitation technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring device, electric/magnetic roughness/irregularity measurement, etc., can solve problems such as difficulty in mastering, high cost, complicated equipment, etc., and achieve easy Easy maintenance and detection, long service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

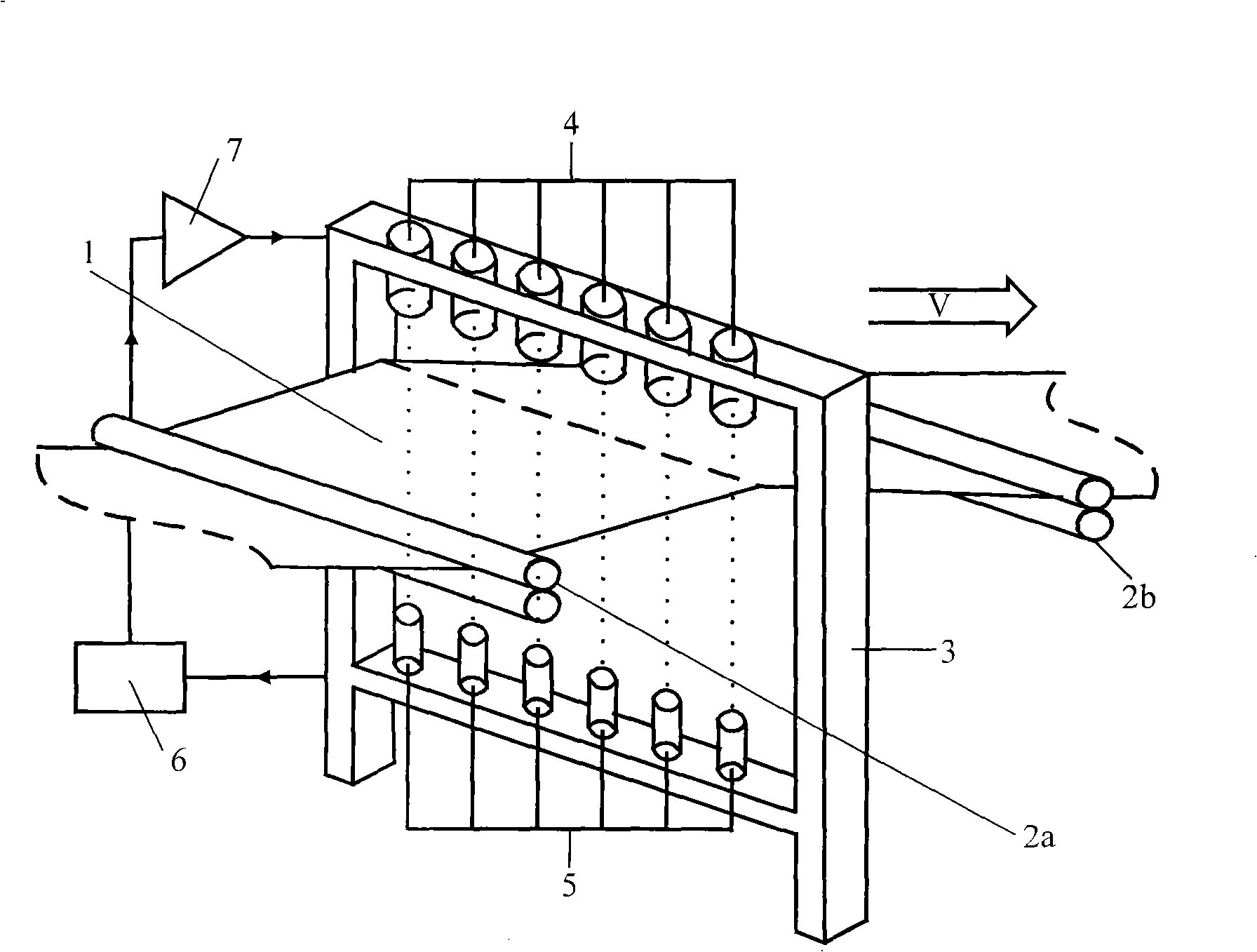

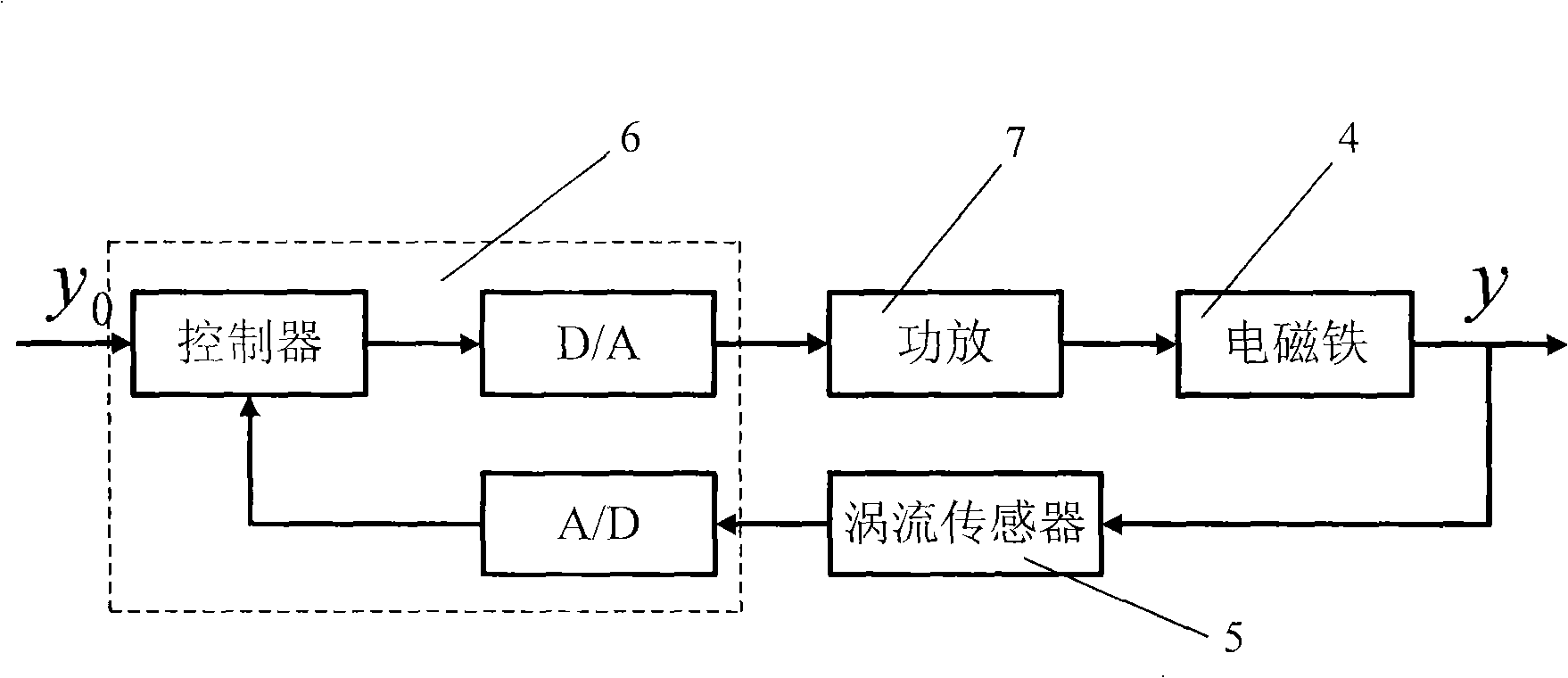

[0040] see figure 1 , figure 2 , a magnetic levitation type dynamic flatness detection method, first the steel strip 1 to be tested is tensioned by the front and rear conveying rollers 2a, 2b, and then the strip steel 1 being conveyed is lifted up by a certain amount perpendicular to the conveying direction through the magnetic levitation control system high. The magnetic levitation control system is composed of electromagnet 4, sensor 5, control computer 6 and power amplifier 7. Several electromagnets 4 correspond to the sensors 5 one by one and are installed above and below the passage of the strip steel 1 on the upper and lower sides of the bracket 3. They are arranged in a row horizontally along the passage direction of the strip steel 1 and completely cover the width of the strip steel. 4 and the number of sensors 5 are five to twenty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com