Rice roughing impurity remover and impurity removing method thereof

A rough selection and paddy technology, applied in the field of agricultural machinery, can solve problems such as low work efficiency, inability to fully utilize machine efficiency, use of organic structures for dust removal and impurity removal equipment, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

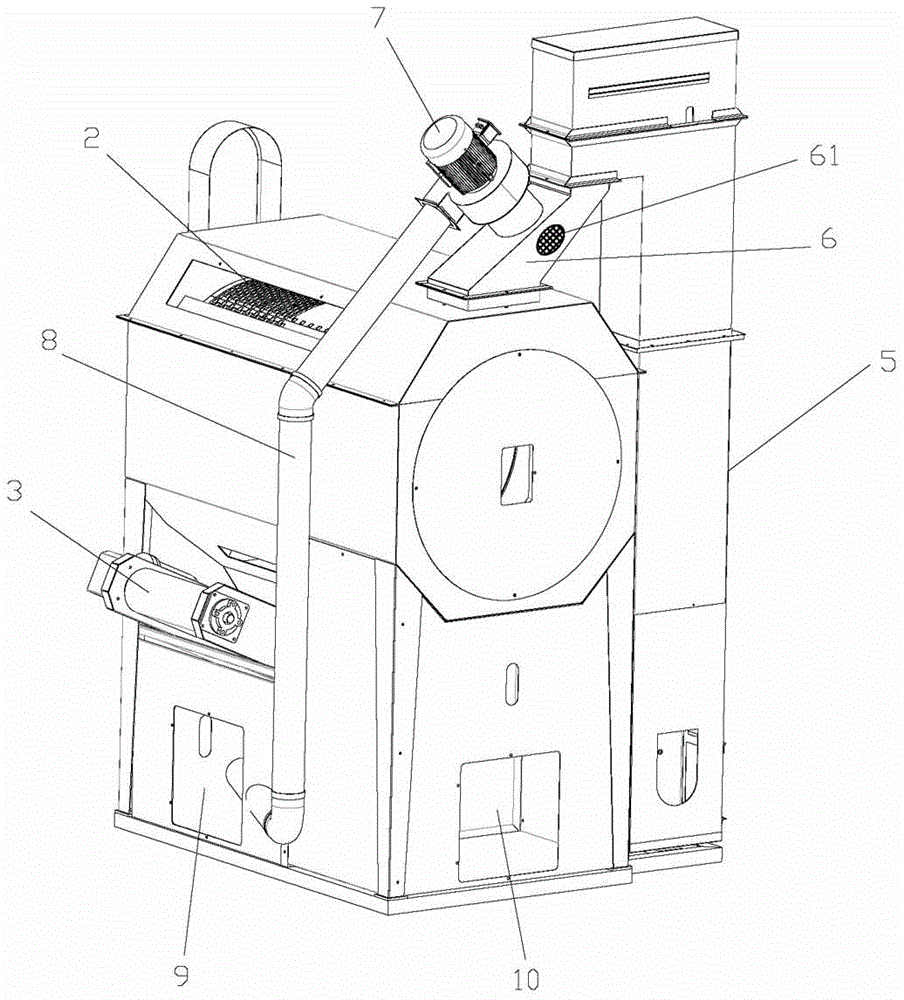

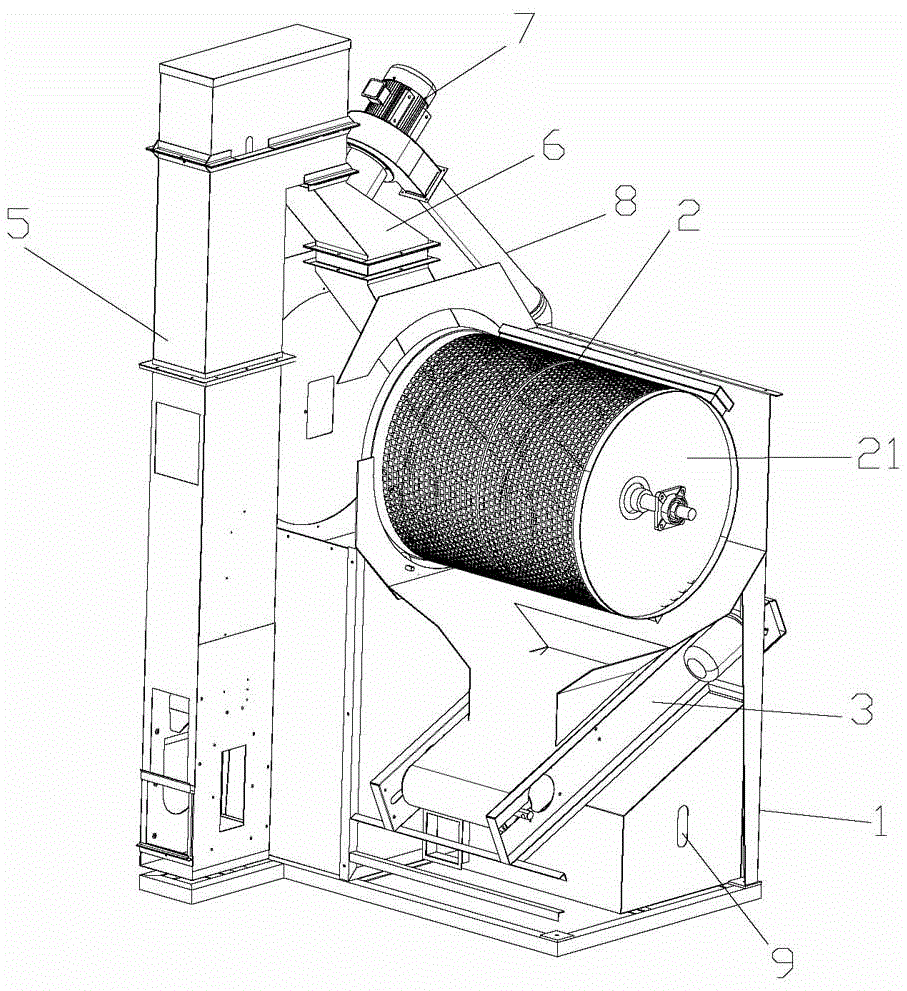

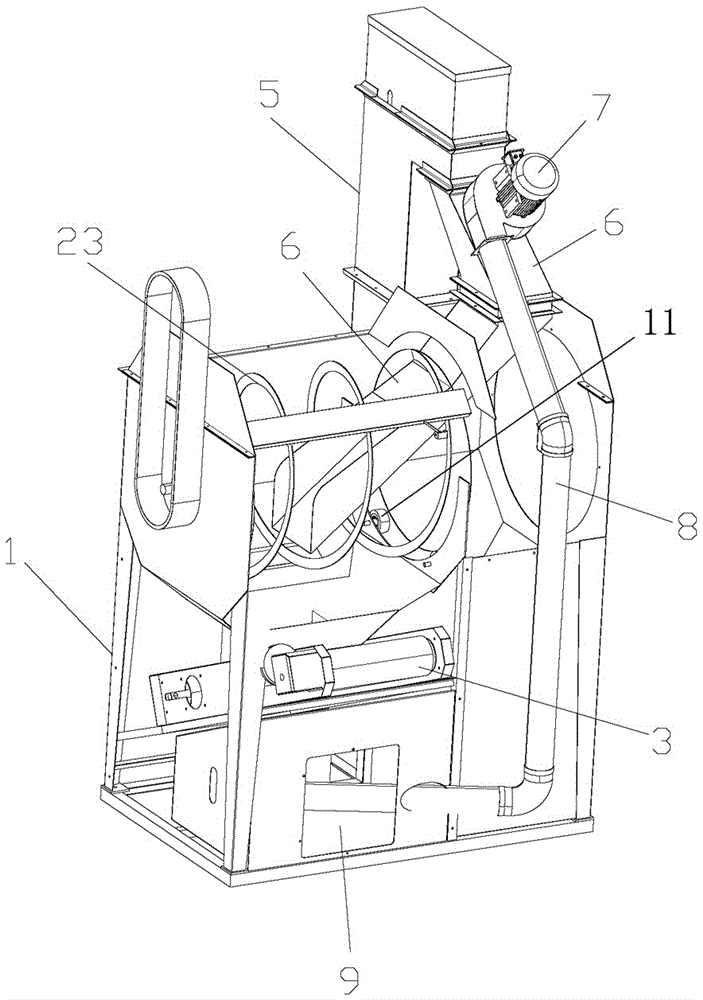

[0016] Such as Figure 1-4 Shown, a kind of paddy roughing and impurity removing machine comprises frame 1; On described frame 1, be provided with horizontally placed roughing drum 2, one end of roughing drum 2 is open and the other end is closed, and the closed end 21 A gear or a pulley is provided at the axial center, and the gear or pulley is connected with the power mechanism through a transmission mechanism. The periphery of the open end 25 close to the rougher drum 2 is provided with a positioning roller 11, and the positioning roller 11 is connected with the rougher drum 2. Cooperate to keep the roughing drum 2 level, the side wall of the roughing drum 2 has a number of sieve holes 22, the inner wall of the roughing drum 2 is also provided with spiral protrusions 23, and the bottom of the roughing drum 2 is provided with a transmission belt device 3. The side of the drum 2 is provided with a lifting mechanism 5, the top of the lifting mechanism 5 is higher than the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com