Feeding mechanism

A technology of feeding mechanism and tray, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inability to realize automatic circulation of product carriers, affect production costs, and low efficiency of loading and unloading materials, so as to facilitate loading and unloading of product carriers , Easy to take and place the product carrier, and easy to take materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

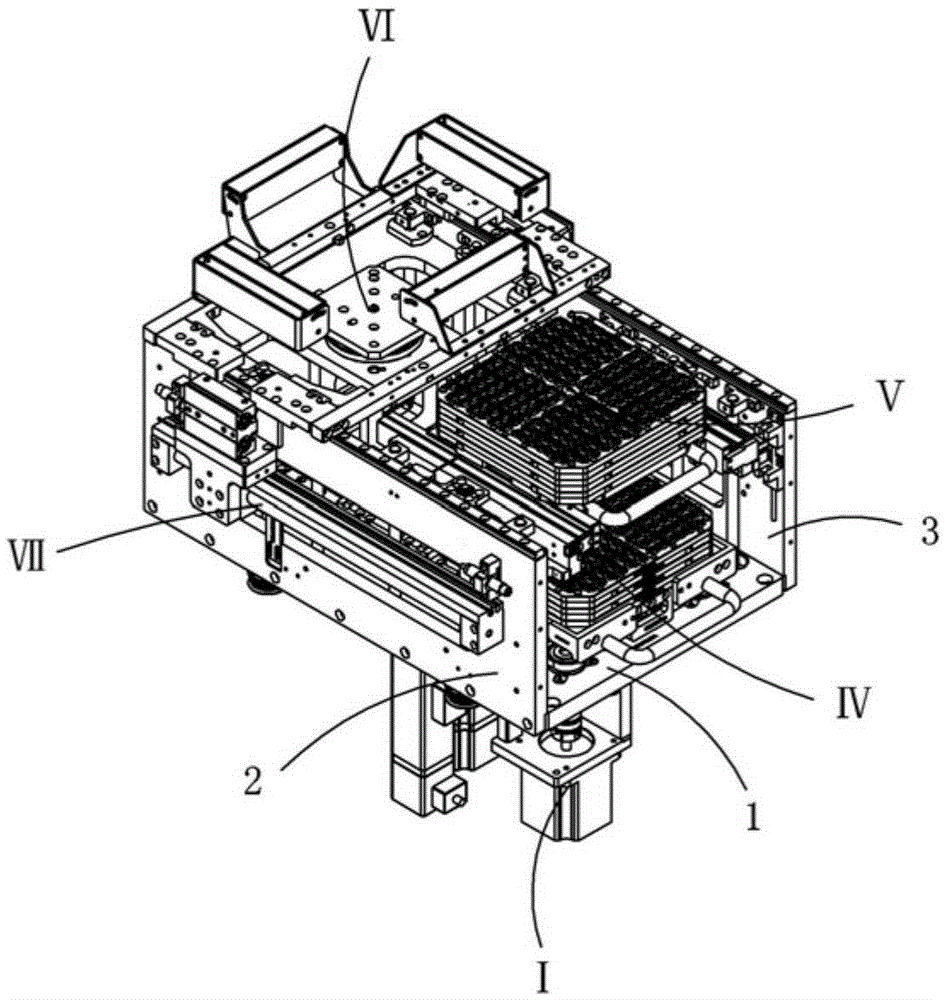

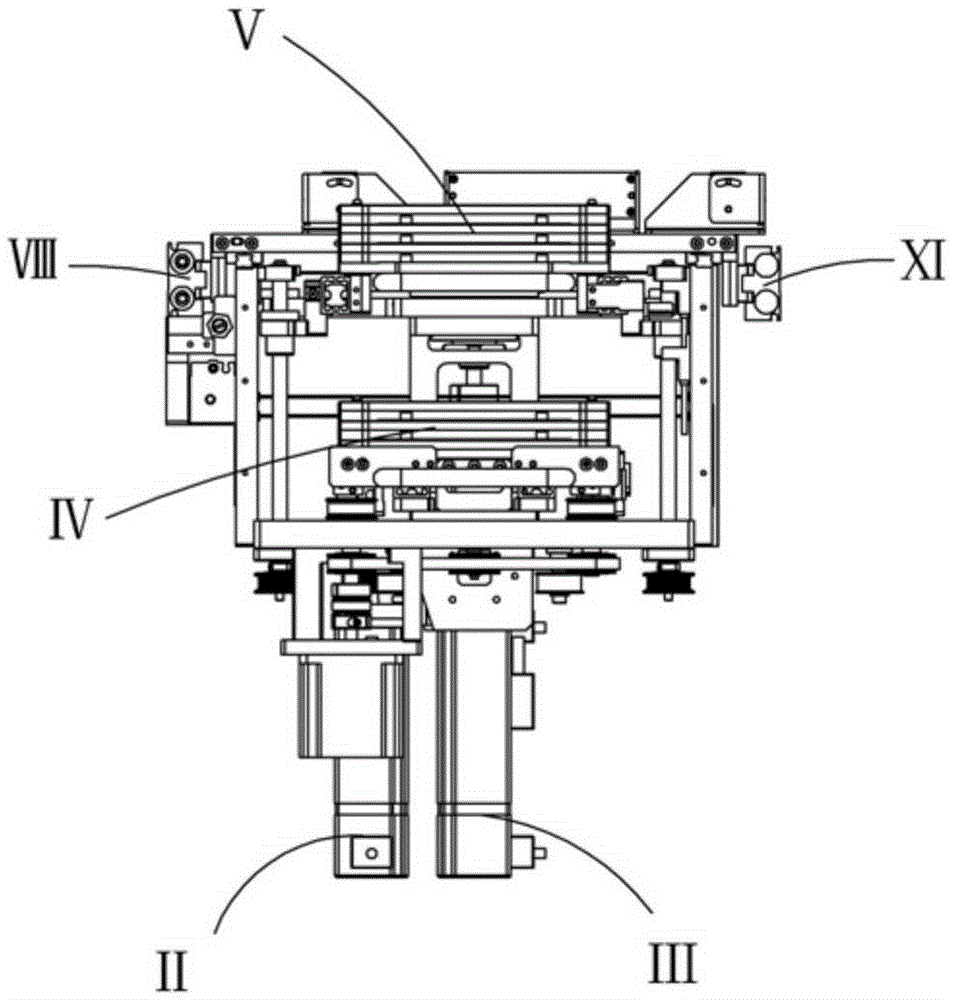

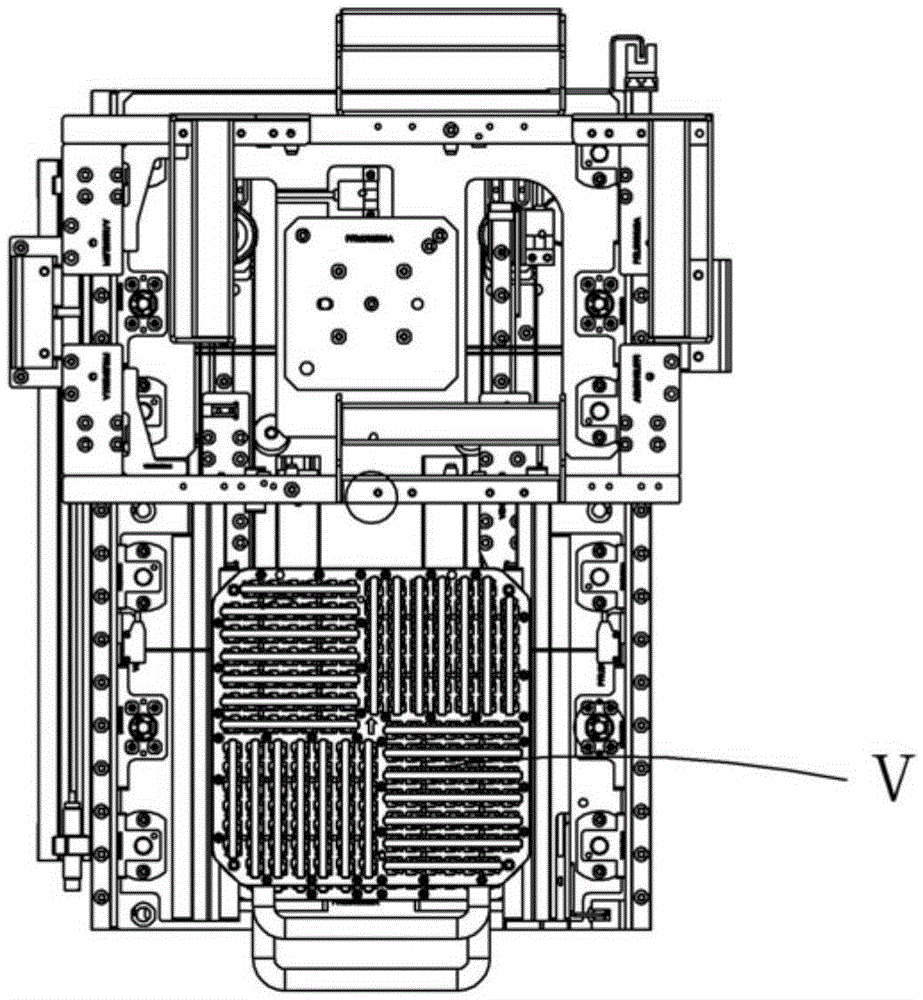

[0038] Examples, see attached Figure 1-15 , a feeding mechanism, the left and right sides of the base plate 1 are respectively equipped with side fixing plates, which are the left fixing plate 2 and the right fixing plate 3, and the translation drive assembly I is installed on the base plate; the base plate and The lifting drive assembly aII and the lifting drive assembly bIII are installed between the left and right fixed plates; the lower tray assembly IV is installed on the upper front side of the bottom plate; the upper tray assembly V is installed on the lift drive assembly a; The above-mentioned lifting drive assembly b is equipped with a rotary feeding assembly VI.

[0039] The translation drive assembly includes a driving motor 4, a driving motor mounting plate 5, a driving motor mounting side plate 6, a driving coupling 7 and a driving driving wheel 8, a driving synchronous wheel 9 and a driving synchronous belt 10, and the driving motor mounting side The plate is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com