Freeze-drying preparation stacking and transfer system and control method

A technology of freeze-dried preparations and control methods, applied in the stacking, transportation and packaging of objects, can solve the problems of reducing the overall speed of the linkage link and increasing the risk of product contamination, eliminating intermediate links and reducing human secretion. pollution, and the effect of reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

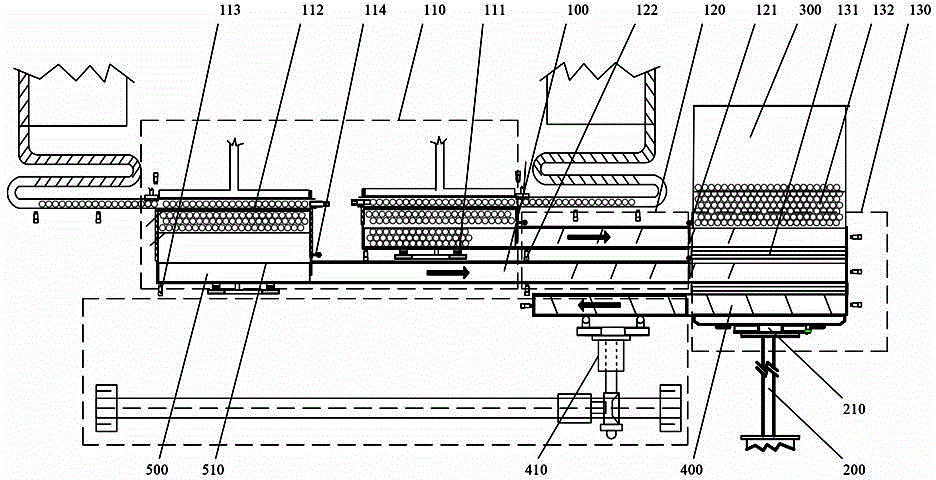

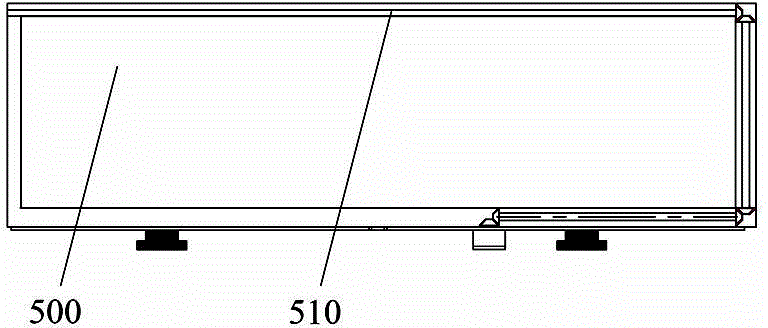

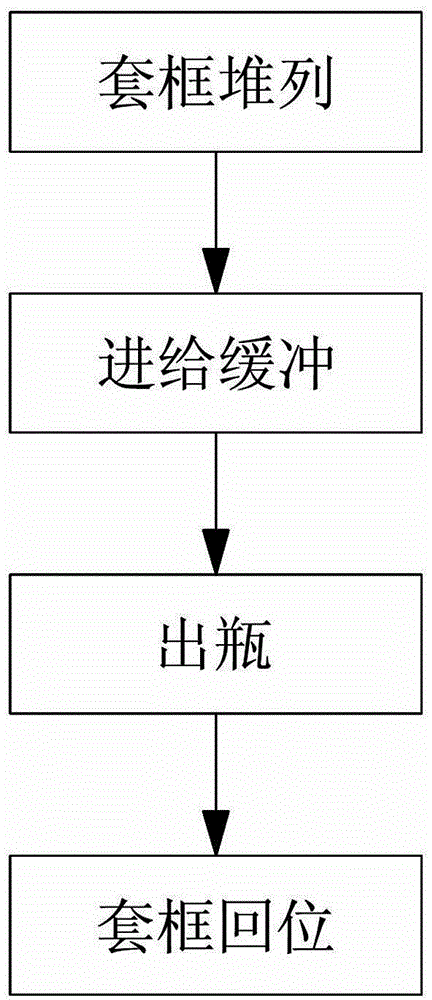

[0060] Figure 1 to Figure 2 It shows an embodiment of a stacking transfer system for freeze-dried preparations of the present invention. The stacking transfer system includes a bottle-feeding push rod 200 and two bottle-feeding mesh belts 100 arranged in parallel. To the bottle outlet end, there are sequentially arranged the stacking frame section 110 for loading the frame 500 after forming the bottle queue, the buffer section 120 for feeding and buffering the frame bottle queue, and sending the frame bottle queue to the freeze dryer The bottle outlet section 130 of the plate layer 300 is provided with a frame conveyor belt 400 parallel to the bottle inlet mesh belt 100, and beside the frame conveyor belt 400, there is a frame loading device 410 for sending the frame 500 to the stack frame section 110, The bottle-feeding push rod 200 is arranged on the side of the bottle-feeding mesh belt 100 away from the freeze-dryer plate 300, and the bottle-pushing end of the bottle-feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com