Integration device based on desulfurization of triazine solution and application method of integration device

An integrated device and solution technology, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve the problems of lack of triazine desulfurizer desulfurization devices and application methods, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

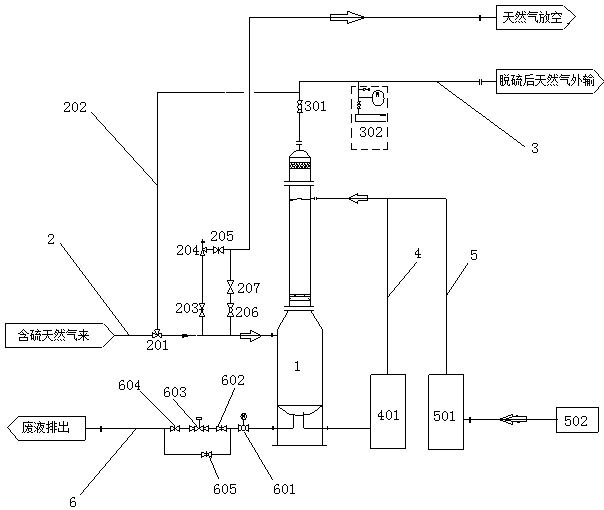

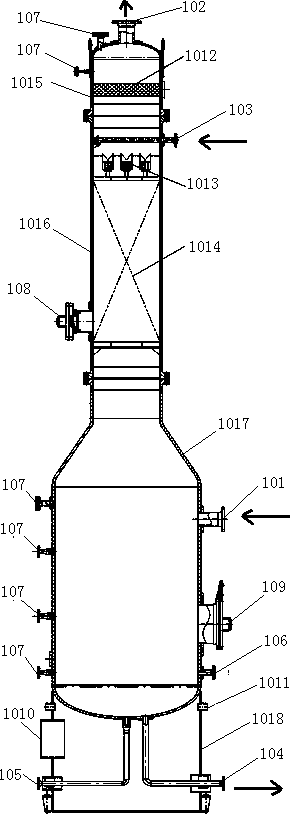

[0032] This embodiment provides a figure 1 The shown integrated device for desulfurization based on triazine solution includes an absorption tower 1, and the absorption tower 1 is provided with an air inlet 101, an air outlet 102, a desulfurizing agent inlet 103, a desulfurizing agent outlet 104 and a sewage outlet 105. The air inlet 101 is connected to the inlet pipeline 2; the gas outlet 102 is connected to the exhaust pipeline 3, and the exhaust pipeline 3 is connected in series from upstream to downstream with a ball valve 1 301 and an online hydrogen sulfide detector 302; the desulfurizer inlet 103 and the desulfurizer outlet 104 are connected by circulation pipeline 4, circulation pipeline 4 is installed with circulation pump 401, desulfurizer inlet 103 is also connected with replenishment pipeline 5, replenishment pipeline 5 is connected with inlet of replenishment pump 501, outlet of replenishment pump 501 is connected with desulfurizer storage tank 502 The sewage outl...

Embodiment 2

[0038] On the basis of embodiment 1, the three-way ball valve 201 is connected in series on the air intake pipeline 2, and the third nozzle of the three-way ball valve 201 is connected with the natural gas external transmission bypass pipeline 202, and the natural gas external transmission bypass pipeline 202 is connected to Into the exhaust line 3.

[0039] Sulfur-containing natural gas can enter the absorption tower 1 through the three-way ball valve 201, or can not enter the absorption tower 1, but can be directly connected to the exhaust pipeline 3 through the natural gas export bypass pipeline 202 to be discharged.

Embodiment 3

[0041] On the basis of Embodiment 1, an electric emergency shut-off valve 601, a shut-off valve 602, an electric discharge regulating valve 603, and a shut-off valve 2 604 are connected in series from upstream to downstream in sequence on the sewage discharge pipeline 6. 602 , a bypass emergency liquid discharge valve 605 arranged in parallel with the liquid discharge electric control valve 603 and the shut-off valve 2 604 .

[0042] Under abnormal working conditions: when the triazine solution in the absorption tower 1 drops to a low level, the electric emergency cut-off valve 601 is used to shut off the sewage pipeline 6 urgently; under maintenance conditions, the discharge pipeline 6 can be cut off through the electric discharge regulating valve 603 ; When the liquid discharge electric control valve 603 fails, the emergency liquid discharge can be realized by bypassing the emergency liquid discharge valve 605 ;

[0043] The shut-off valve 1 602 and the shut-off valve 2 604 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com