Partial annealing device and annealing method of bearing sleeve ring

A bearing ring, local annealing technology, used in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as affecting the performance and service life of bearings, the hardness of the inner hole of the screw hole bearing cannot be reduced to the specified value, and the thread cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

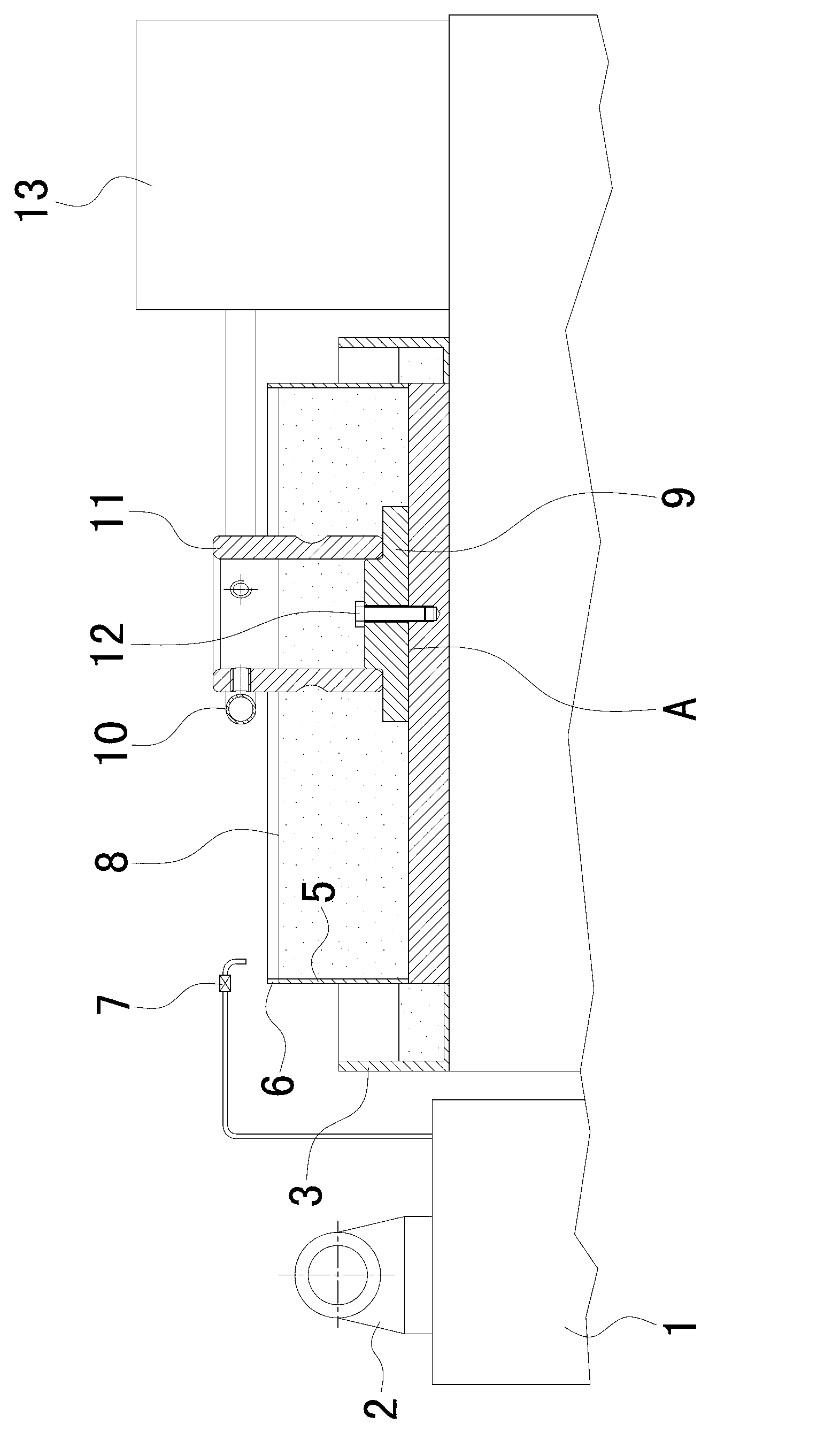

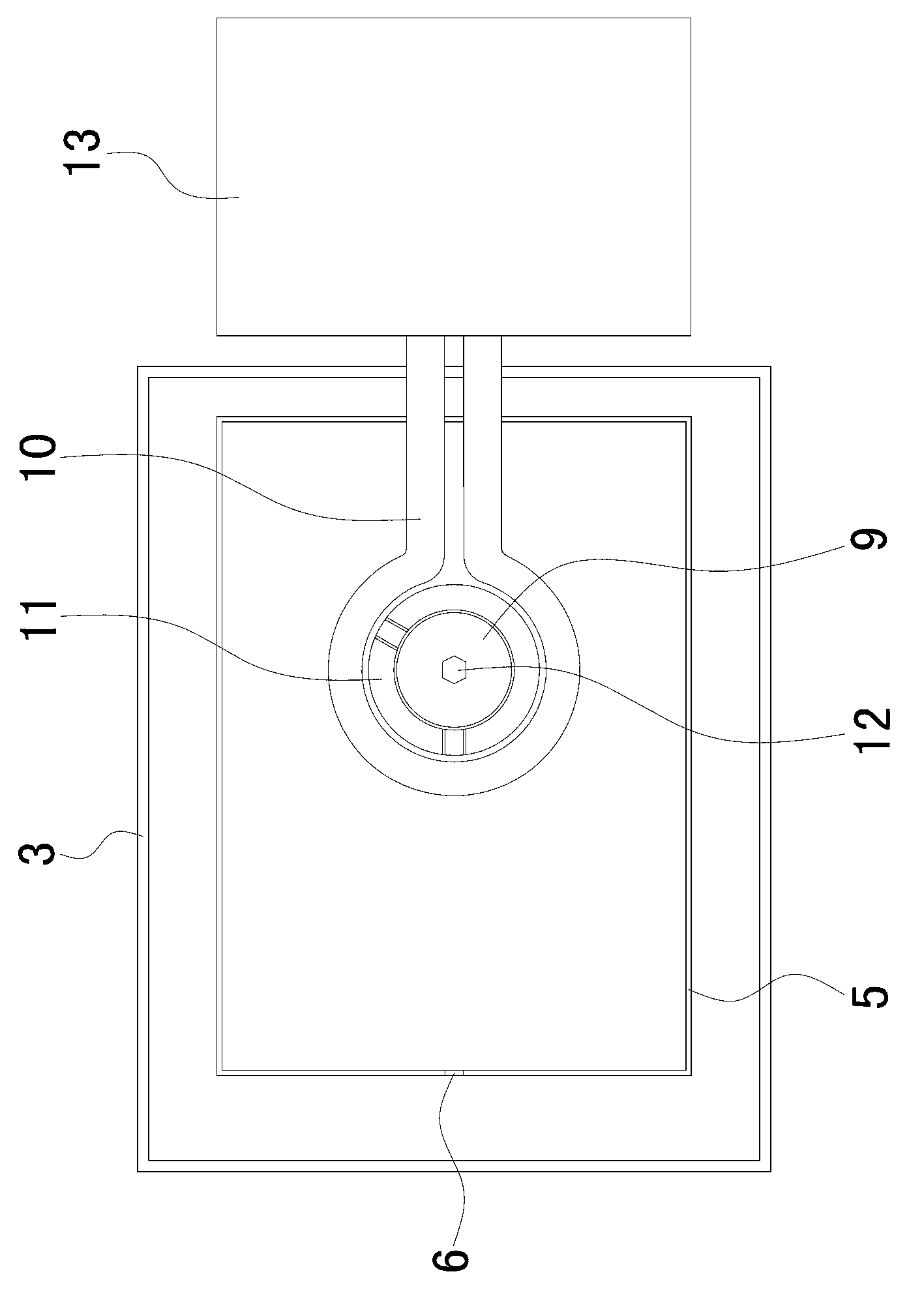

[0016] see figure 1 , 2 , a local annealing device for bearing rings, including a high-frequency induction heater 13, the high-frequency induction heater 13 has an annular heating tube 10. The device also includes a cooling water tank 5, a backflow tank 3 and a cooling water tank 1 with a water pump 2. The cooling water tank 1 is provided with a water adding pipe extending toward the cooling water tank 5. The wall of the cooling water tank 5 is provided with an overflow port 6, and the back flow tank 3 Located downstream of the overflow port 6, a return pipe (not shown in the figure) is provided between the return tank 3 and the cooling water tank 1, and the station A for clamping the bearing ring 11 is provided in the cooling water pool 5, and the annular heating pipe 10 The arc part of the is located directly above the station.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com