Numerical control machine tool for milling inner bores and outer circles and machining method

A technology of milling processing and CNC machine tools, which is applied in the direction of metal processing equipment, manufacturing tools, boring/drilling, etc., can solve problems such as inability to meet processing requirements, achieve the effect of reducing the requirements for programming capabilities and simplifying programming methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

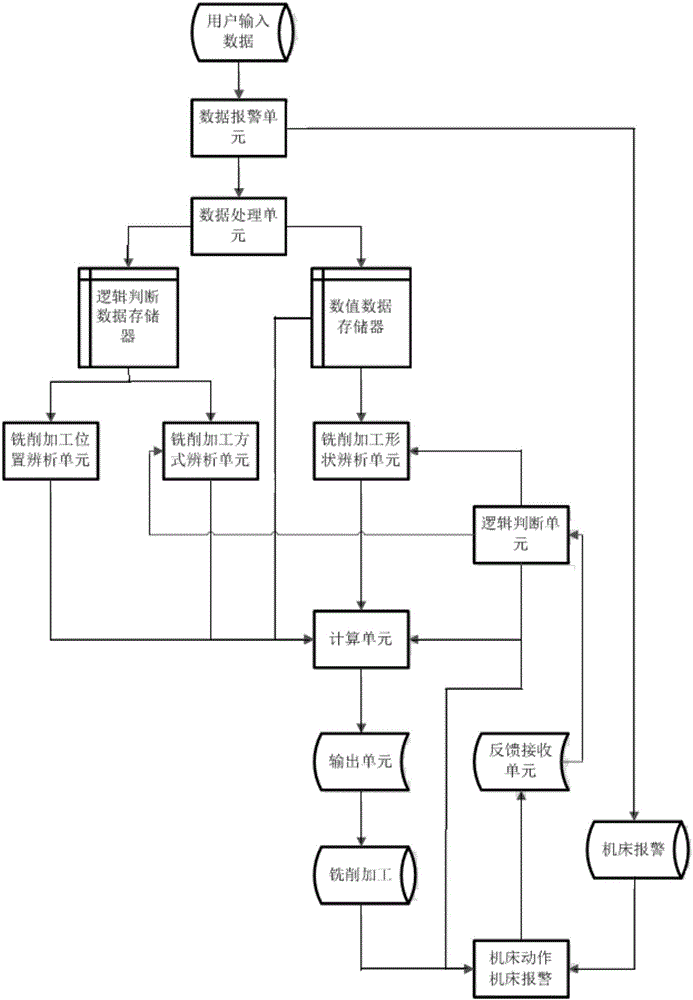

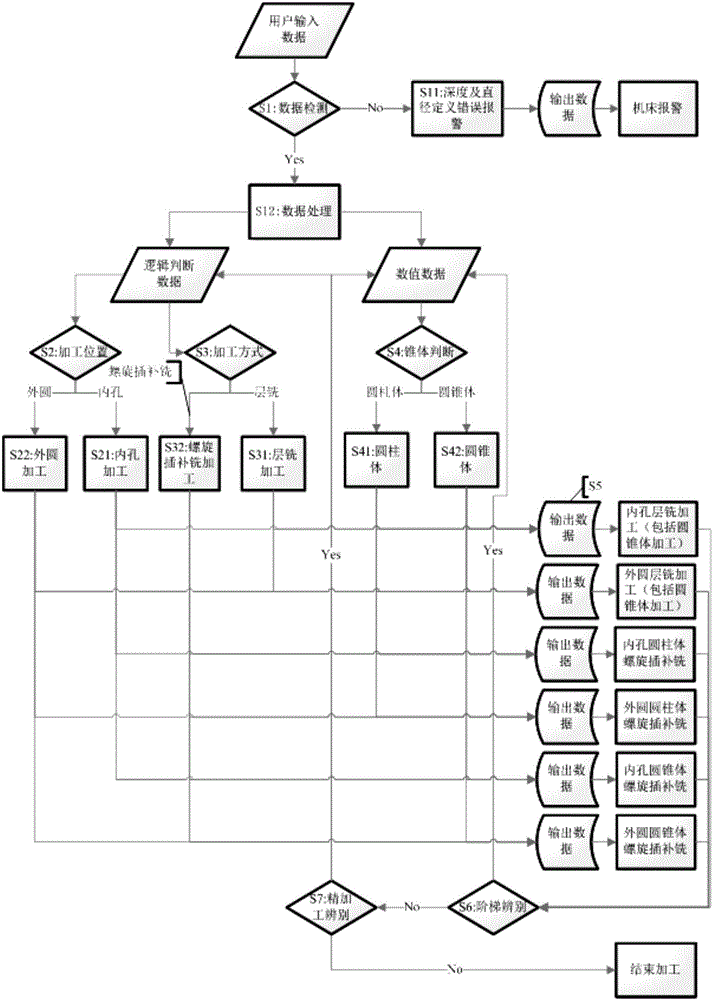

[0043] Embodiments of the present invention are described below with reference to the drawings, in which like components are denoted by like reference numerals.

[0044] The invention adds a milling module for hole and outer circle processing on the numerical control machine tool used for milling holes and outer circles. The CNC machine tool accepts the relevant dimensions and processing methods of milling holes and outer circles input by users in the form of CNC macro codes, and transfers these data into the milling module. The CNC machine tool is controlled by the milling module to mill the hole and the outer circle, and the processing position is continuously identified until the specified depth is reached, and the milling of the hole and the outer circle is completed.

[0045] The input data contains:

[0046] 1) Selection of milling machining position (inner hole machining, outer circle machining).

[0047] 2) Selection of milling rough machining methods (layer milling,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com