Numerical control machine tool for hole machining and hole machining method thereof

A hole processing method and technology of numerically controlled machine tools, applied in the field of mechanical processing, can solve problems such as inability to meet parts processing requirements, achieve the effects of reducing error probability and programming time, increasing processing flexibility, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

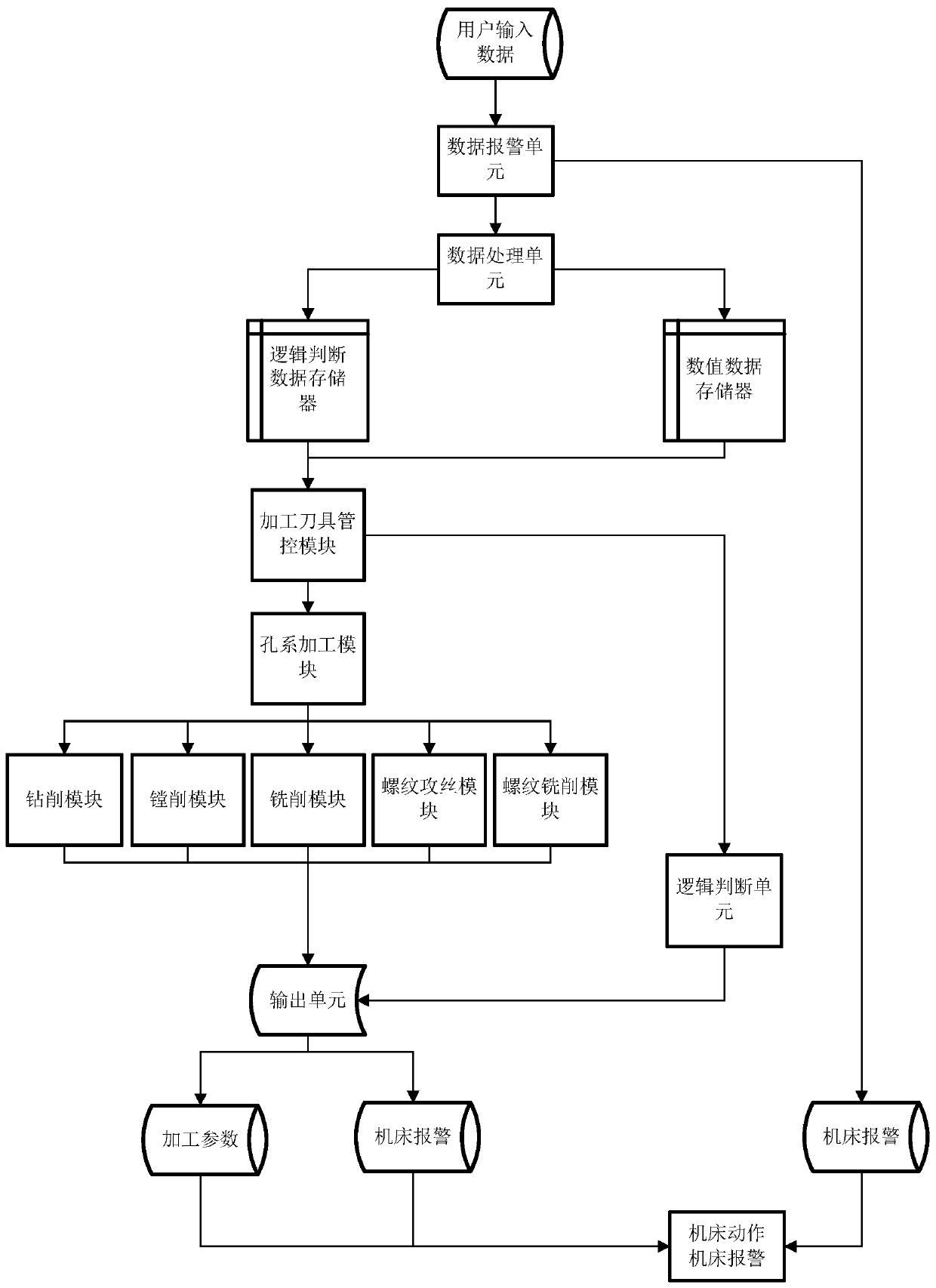

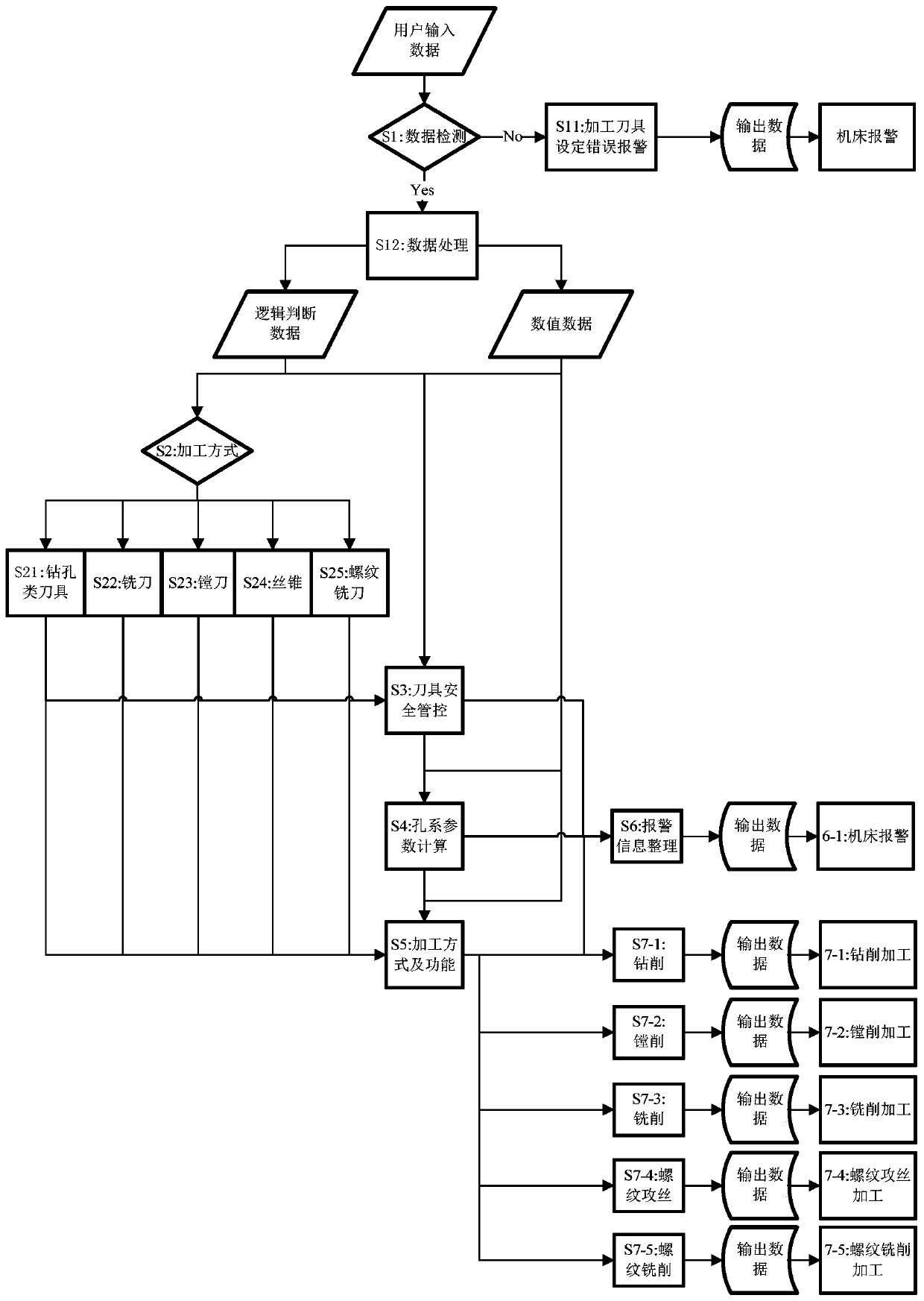

[0052] Embodiments of the present invention will be described below in conjunction with the accompanying drawings, but the scope of protection of the present invention should not be limited thereto.

[0053] In the present invention, a hole processing module for hole processing is additionally installed on the numerical control machine tool. The CNC machine tool accepts data such as the relevant dimensions and processing methods of hole processing input by the user in the form of CNC macro codes, and transfers these data into the hole processing module, and then controls the CNC machine tool to perform hole processing operations through the hole processing module. Tool collision detection, tool life processing parameter detection, backlash compensation, hole system calculation, processing parameter calculation, and control the processing actuator of the CNC machine tool to complete hole processing.

[0054] The input data contains:

[0055] 1) The initial hole coefficient of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com