Cooling liquid recovering structure for blow-molding of chemical experimental containers

A blow molding and chemical experiment technology, applied in the field of plastic products, can solve problems affecting product flatness, difficult to control product quality, plastic film deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

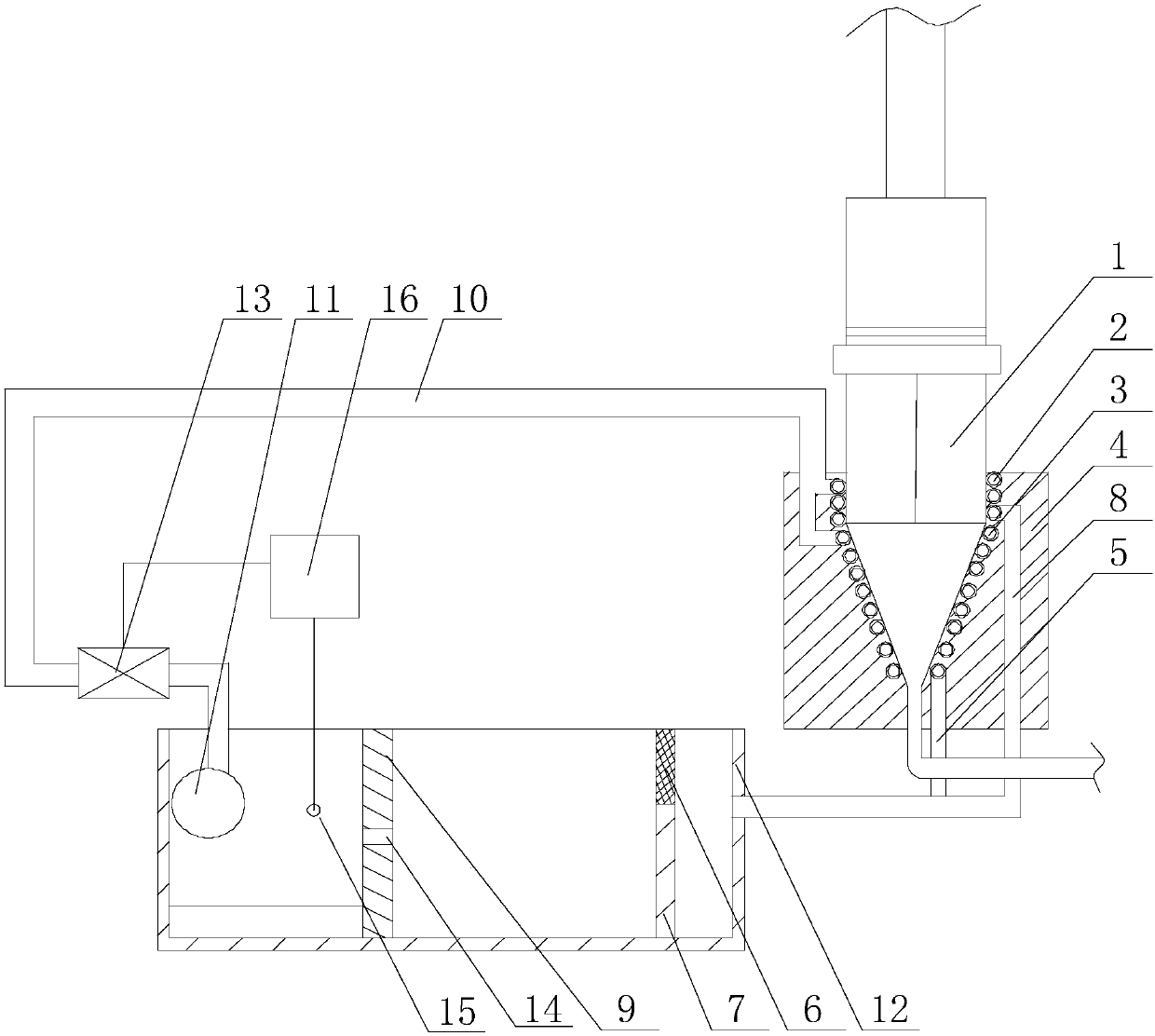

[0020] Such as figure 1 As shown, this embodiment includes a pool body 12 and a water pump 11 fixed on the side wall of the pool body 12. A baffle 7 is arranged at the bottom of the pool body 12, and the baffle plate 7 separates the pool body 12 into mutually independent The sedimentation chamber and the liquid storage chamber, the water pump 11 is placed in the liquid storage chamber, and the horizontal height of the baffle plate 7 is smaller than the depth of the pool body 12, and also includes a heat insulation block 4 sleeved on the outer wall of the discharge section 1 of the blow molding machine, A first branch pipe 2 and a second branch pipe 3 are provided inside the heat insulating block 4, and the first branch pipe 2 is spirally wound at the beginning of the discharge section 1 of the blow molding machine, and the second branch pipe 3 is spirally wound on the blow molding machine. The end of the discharge section 1 of the plastic machine is connected with a liquid out...

Embodiment 2

[0024] Such as figure 1 As shown, in this embodiment, an electric heating plate is provided at the bottom of the liquid storage chamber, and the electric heating plate is located between the liquid storage chamber and the side wall of the separator 9 away from the precipitation chamber, and the electric heating plate passes through The wire is electrically connected with the PLC control box 16 . When the temperature value detected by the temperature sensor 15 is less than the temperature value required by the discharge section 1 of the blow molding machine, the PLC control box 16 starts the electric heating plate while controlling the solenoid valve 13 to be closed, so that the electric heating plate is positioned at its positive position. The cooling liquid above is heated until the detection value of the temperature sensor 15 is slightly higher than the temperature value required by the discharge section 1 of the blow molding machine. The PLC control box 16 controls the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com