Carrying drive assembly

A technology for handling drive components and components, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low loading and unloading efficiency, high labor intensity, and affecting production costs, and achieve the effect of convenient material retrieval and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

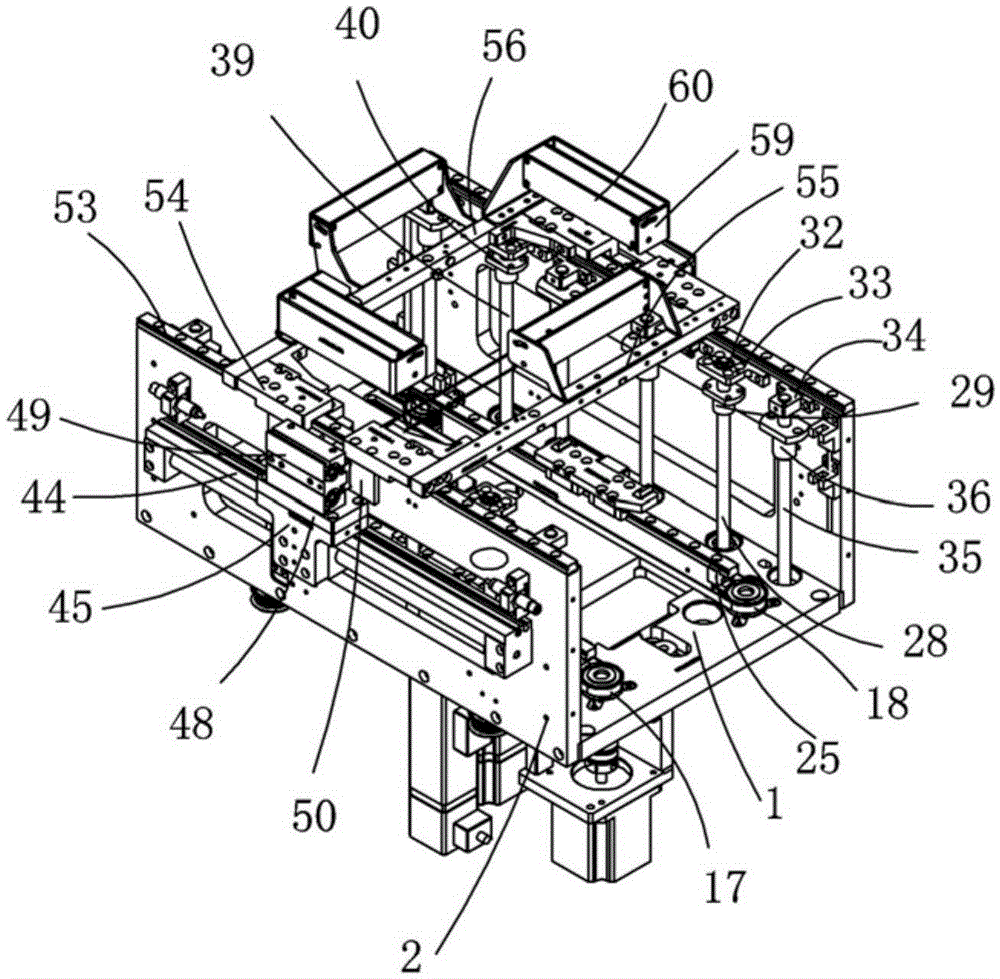

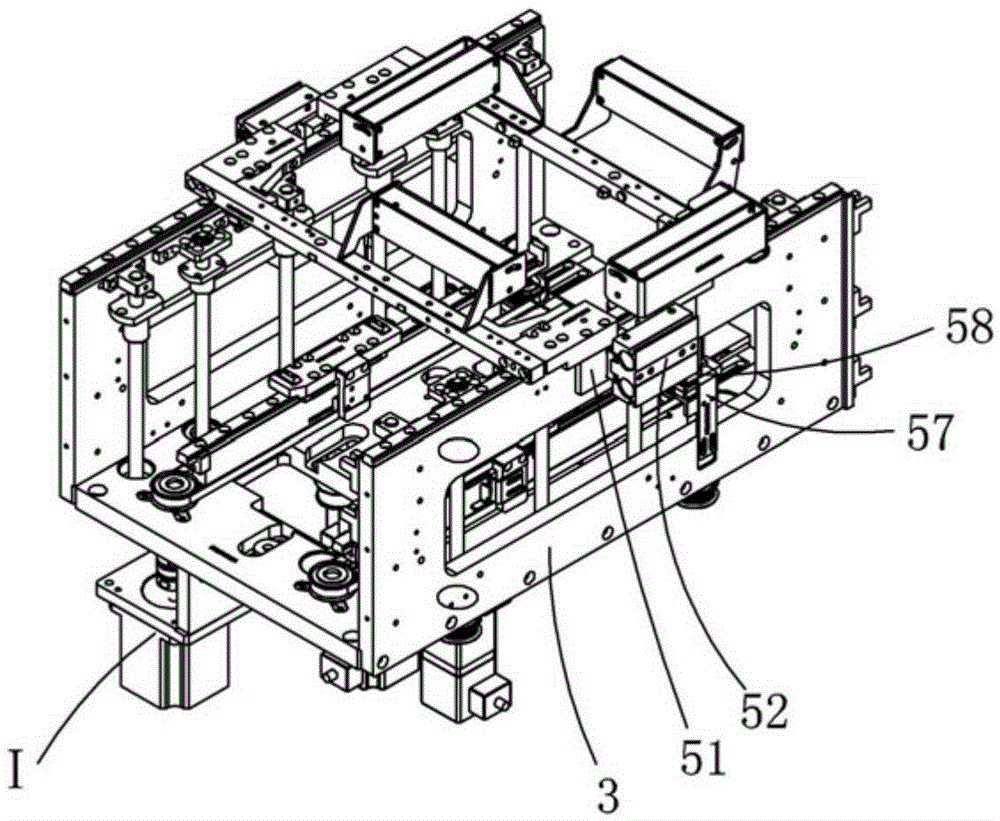

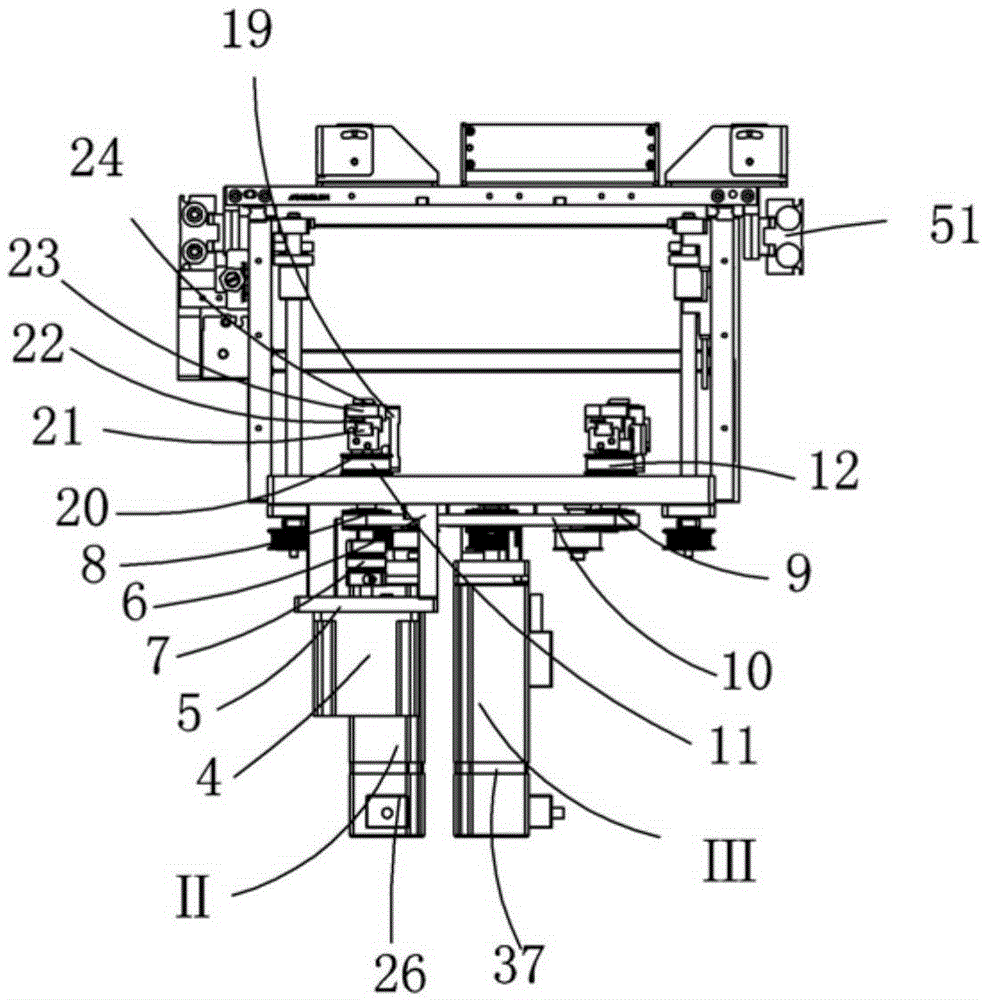

[0024] Examples, see attached Figure 1~6 , a handling drive assembly, including a base plate 1, side fixing plates are respectively installed on the left and right sides of the base plate, which are the left fixing plate 2 and the right fixing plate 3, and the translation driving assembly I is installed on the base plate; The translation drive assembly includes a driving motor 4, a driving motor mounting plate 5, a driving motor mounting side plate 6, a driving coupling 7 and a driving driving wheel 8, a driving synchronous wheel 9 and a driving synchronous belt 10, and the driving motor mounting side plate Installed on the bottom of the base plate, the drive motor installation plate is installed on the lower end of the drive motor installation side plate, and the drive motor is installed on the drive motor installation plate; There is a driving driving wheel, a driving synchronous shaft is installed on the base plate, a driving synchronous wheel is installed on the driving s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com