Error correction method for pressure sensor and calorimeter for measuring pressure by using the same

A pressure sensor and error correction technology, applied in the field of heat meters, can solve the problems of many pressure points, inability to guarantee errors, and inability to ensure the accuracy of pressure measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

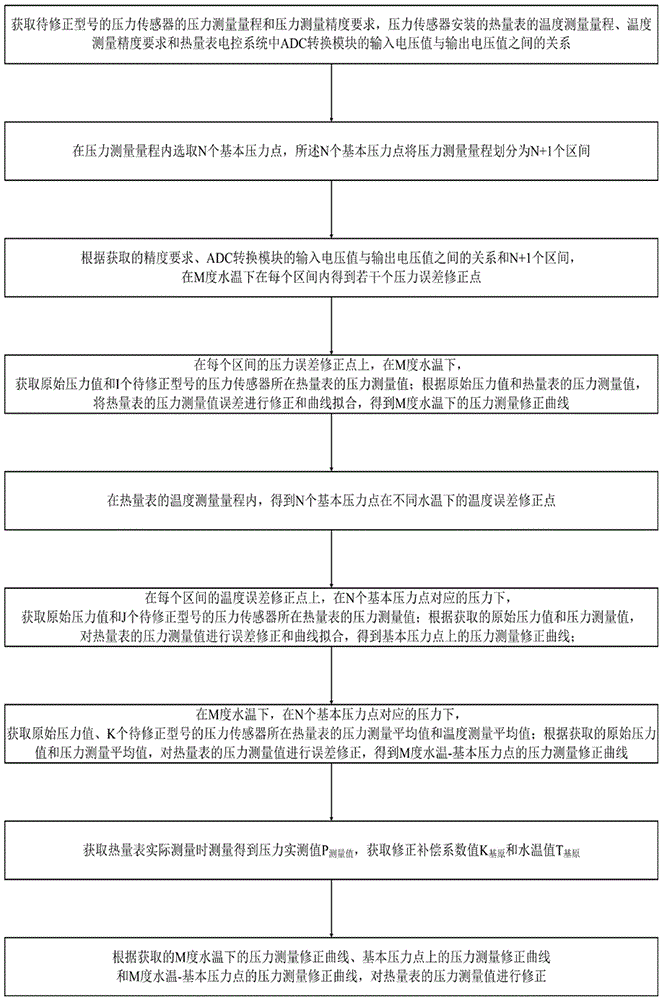

[0050] Such as figure 1 Shown is the flow chart of the method of the present invention: the pressure sensor error correction method provided by the present invention includes the following steps:

[0051] S1. Obtain the pressure measurement range and pressure measurement accuracy requirements of the pressure sensor to be corrected, the temperature measurement range and temperature measurement accuracy requirements of the heat meter installed on the pressure sensor, and the input voltage value and output of the ADC conversion module in the heat meter electronic control system The relationship between voltage values;

[0052] The ADC conversion module is the ADC conversion module that comes with the heat meter controller; the model of the heat meter controller is MSP430F4793.

[0053] The described relationship between the input voltage value and the output voltage value of obtaining the ADC conversion module specifically includes the following steps:

[0054] ⅰ. Definition V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com