Digital wide-range ultra-high precision coil shaper

A large-scale, digital technology, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve problems such as poor safety, small control range, and large pressure measurement error, and achieve high pressure control accuracy and improve The effect of improving pressure measurement accuracy and improving the safety of equipment work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

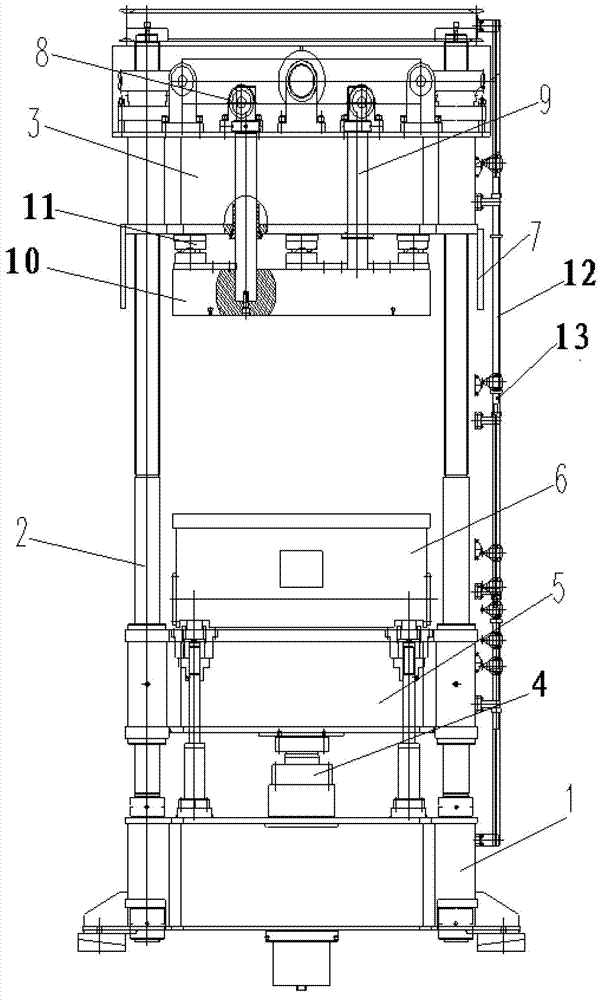

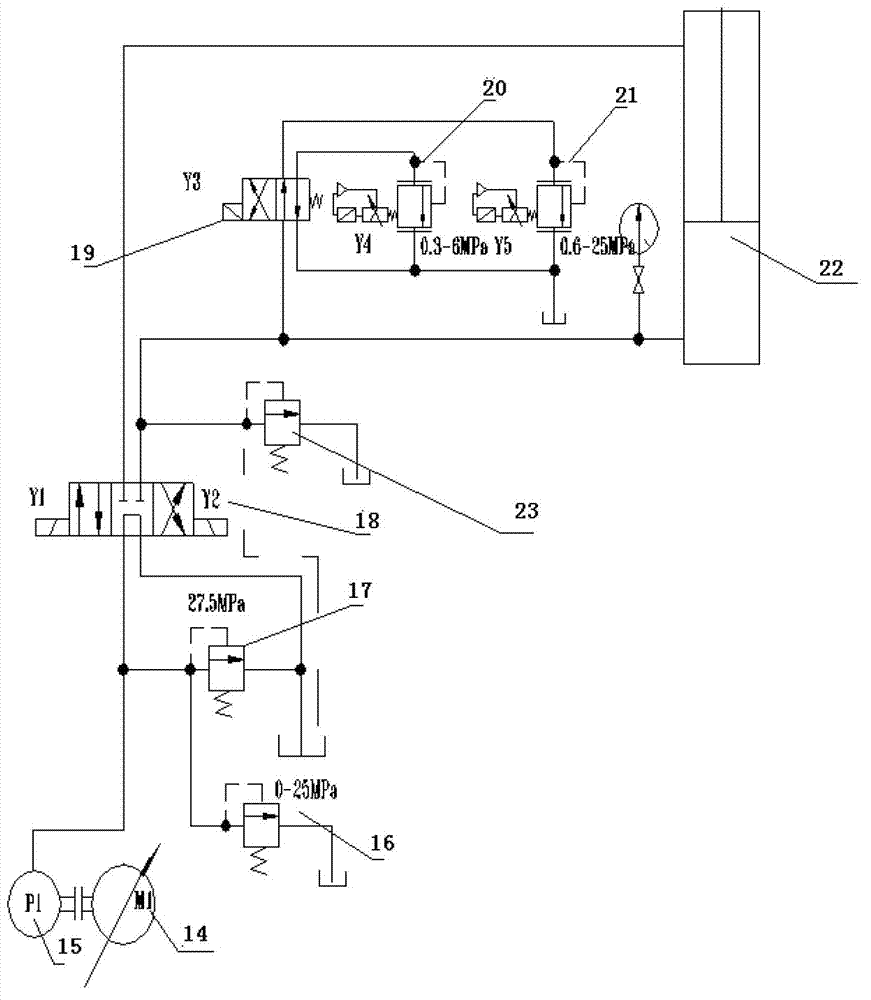

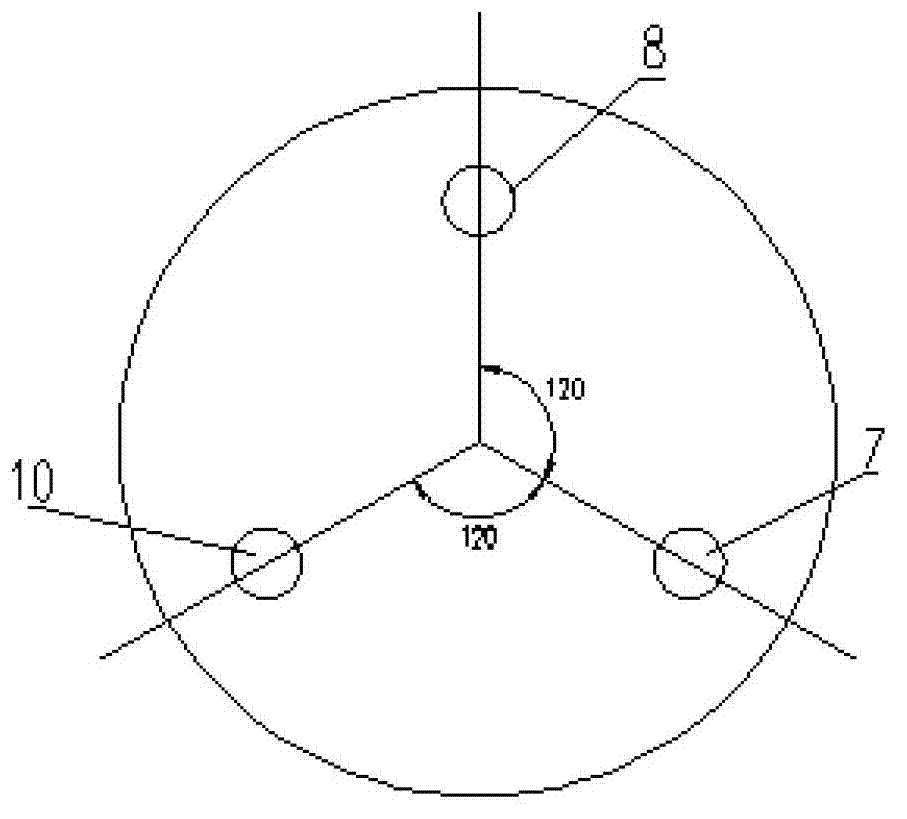

[0015] Such as figure 1 shown. The digital large-scale ultra-high-precision coil shaping machine includes a mechanical part and a hydraulic control system that controls the mechanical part. The mechanical part includes a lower beam 1, and vertical guide columns 2 are installed on both sides of the lower beam 1. The top of the guide column 2 is jointly supported by an upper beam 3 suspended above the lower beam 1. The lower beam 1 is also provided with an oil cylinder 4 with a vertically upward piston rod. The top of the piston rod of the oil cylinder 4 supports a slider 5, and the side of the slider 5 The upper part is slidingly installed on the guide column 2, the sliding block 5 is equipped with a mobile platform 6, the photoelectric protector 7 is respectively installed on both sides of the bottom of the upper beam 3, and a plurality of turbines 8 are installed on the top of the upper beam 3, and each turbine 8 is respectively A vertical worm 9 is engaged, and a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com