Spray dyeing equipment for textile machinery

A technology of textile machinery and equipment, applied in the field of spraying and dyeing equipment, can solve the problems of unable to clean the spraying range of the pipeline, difficult to control, narrow control range of dye injection pressure, etc., and achieve large spraying range, sufficient atomization, and work adaptability big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

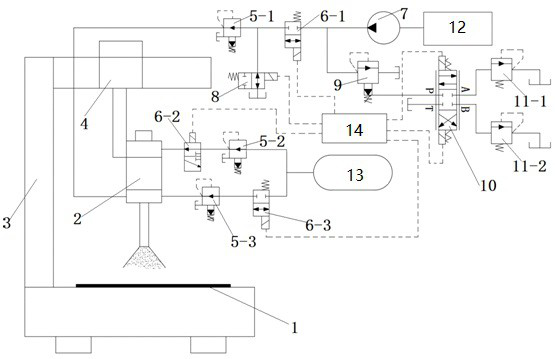

[0024] Please combine figure 1 As shown, the spray-dyeing equipment for textile machinery involved in the embodiment of the present invention has a spray-dyeing base 3, and the spray-dyeing base 3 is used to place the textile 1 to be dyed. Fix the column on one side of the dyeing base 3, and install a beam above the dyeing base 3 on the top of the column. The translation mechanism 4 is installed on the beam, and the dyeing valve 2 is connected with the translation mechanism 4. Through translation The action of the mechanism 4 enables the spray-dyeing valve 2 to reach various positions of the textile fabric 1 to be dyed for spray-dyeing. Wherein the translation mechanism 4 can adopt the moving mechanism commonly used in the prior art, and its specific structure will not be repeated here.

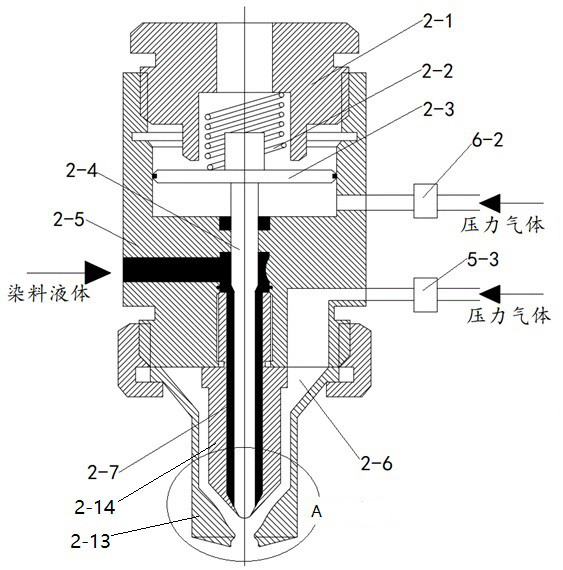

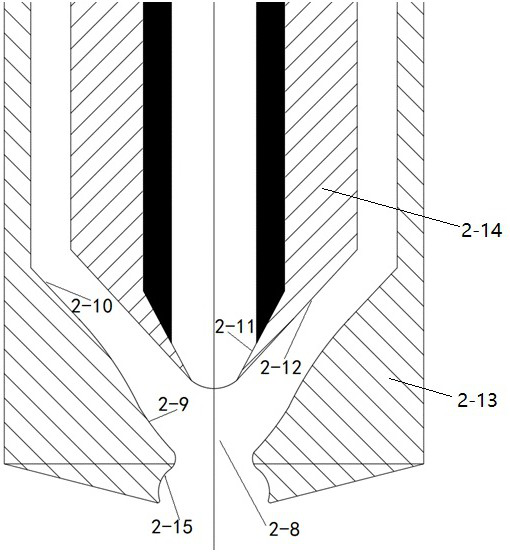

[0025] The spray dyeing equipment for text...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com