A kind of titanium matrix composite material and preparation method thereof

A titanium-based composite material and titanium powder technology, applied in the field of composite materials, can solve problems such as insufficient material properties, and achieve the effects of shortening sintering time, improving mechanical properties, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The mass ratio of carbon nanotube powder to graphene oxide is selected as 1:0 to prepare carbon nanotube reinforced titanium matrix composite:

[0032] 1. Add 0.084 g of carbon nanotube powder to absolute ethanol, and mix with an ultrasonic stirrer to obtain an alcohol solution of carbon nanotubes;

[0033] 2. Add 14 g of titanium powder to the alcohol solution of carbon nanotubes, the mass ratio of carbon nanotubes and titanium powder is 1: 167, and mix with an ultrasonic stirrer to obtain a mixed solution of carbon nanotubes and titanium powder;

[0034] 3. Stir the mixed solution of carbon nanotubes and titanium powder in a water bath stirrer at 60°C for about 4 hours until it is basically dry, and then dry it in an oven at 60°C for 12 hours to dry thoroughly to obtain a mixed powder of carbon nanotubes and titanium powder;

[0035] 4. Put the mixed powder obtained in step 3 into the mold of the hot-pressed sintering furnace, and then put it into the vacuum hot-press...

Embodiment 2

[0040] Select the mass ratio of carbon nanotube powder and graphene oxide as 1:0.1 to prepare graphene oxide / carbon nanotube reinforced titanium matrix composite:

[0041]1. Using the improved Hummers method, refer to the document Improved Synthesis of Graphene Oxide.Marcano DC, ACS NANO, 2010,4(8):4806-4814 (improved synthesis method of graphene oxide. Marcano DC, ACS NANO, 2010, Vol. 4, No. 8, pp. 4806-4814), Preparation of Graphene Oxide Solutions. The actual graphene oxide content is 0.0084g, and the part taken out is diluted with absolute ethanol to obtain the diluted graphene oxide solution;

[0042] 2. Add 0.084 g of carbon nanotube powder to the diluted graphene oxide solution, so that the mass ratio of carbon nanotubes and graphene oxide is 1: 0.1, and mix with an ultrasonic stirrer to obtain graphene oxide / carbon nanotube mixture;

[0043] 3. Add 14g of titanium powder to the mixed solution of graphene oxide / carbon nanotubes, so that the mass ratio of carbon nanotu...

Embodiment 3

[0049] The mass ratio of carbon nanotube powder to graphene oxide is selected as 1:1 to prepare graphene oxide / carbon nanotube reinforced titanium matrix composite. The difference with embodiment 2 is:

[0050] In step 1, after the actual graphene oxide content is 0.084g, the part taken out is diluted with absolute ethanol to obtain the diluted graphene oxide solution, so that after adding 0.084g carbon nanotubes in step 2, carbon nanotubes and graphene oxide The mass ratio is 1:1.

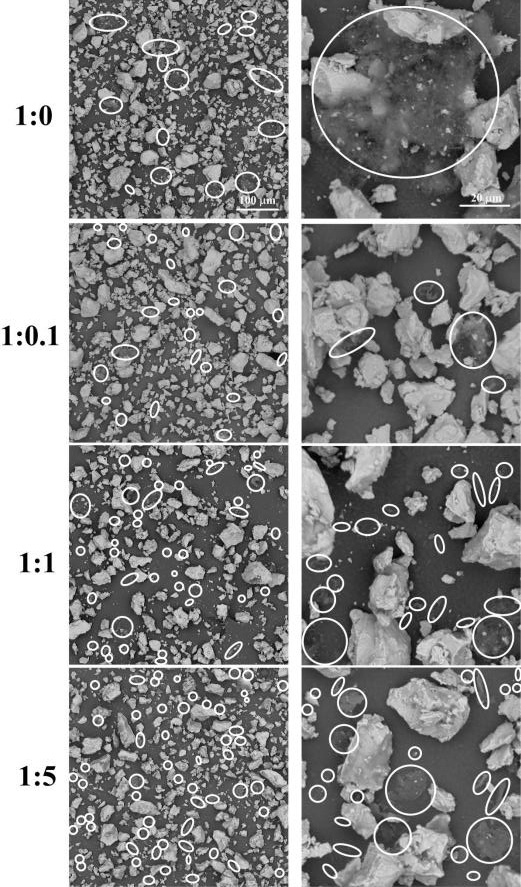

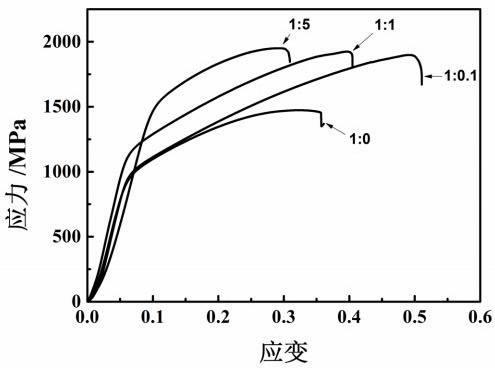

[0051] From figure 1 (The picture marked with 1:1) It can be seen that in the mixed powder of this example, the distribution of carbon nanotube aggregates is significantly more uniform, the size of carbon nanotubes is smaller than that in Example 2, and the carbon nanotubes in the aggregates are more sparse. And in some regions, completely independent single carbon nanotubes have appeared, and the increase in the proportion of graphene oxide is conducive to the improvement of the dispersion of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com