Independent hydraulic oil source for vehicle

A hydraulic oil source, independent technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of shifting failure, failure to select upper position, wrong position selection, etc., to achieve work safety Reliable, simple structure, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

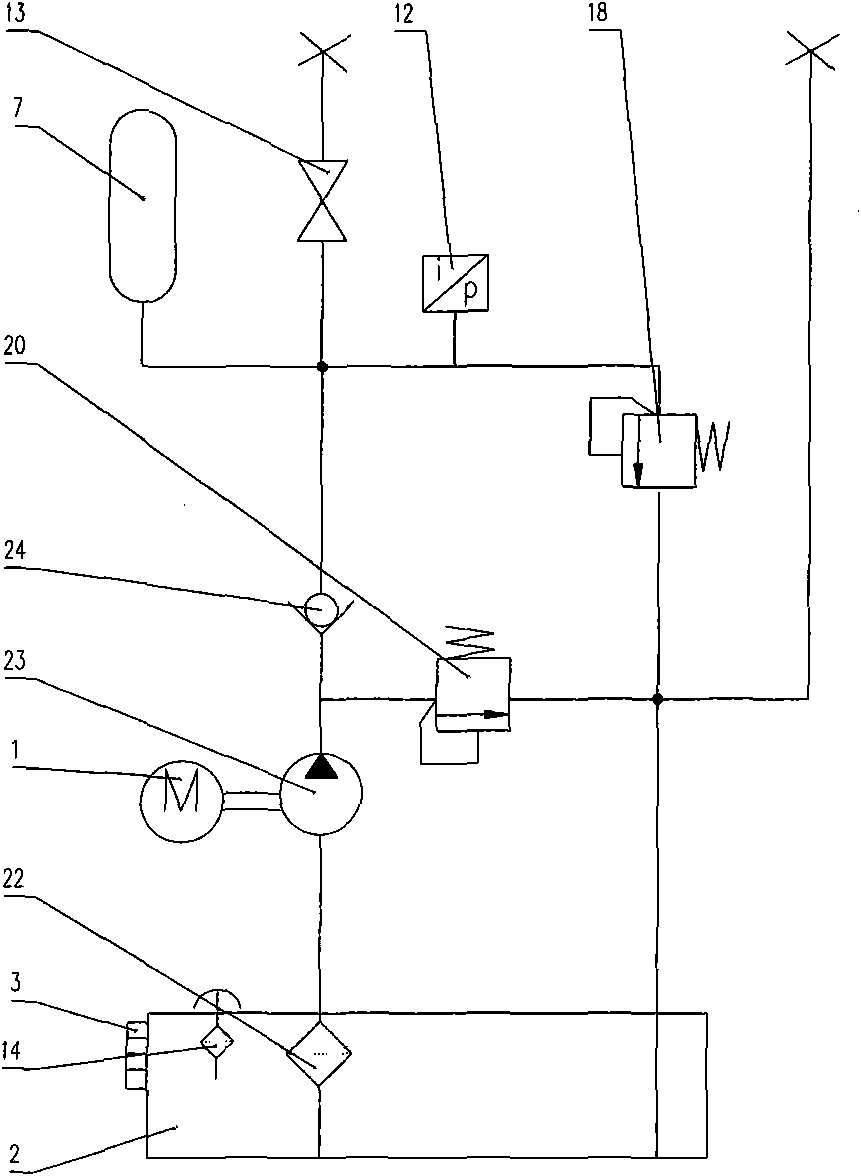

[0013] 1. Schematic diagram of oil source system

[0014] figure 1 It is the schematic diagram of oil source system. In the figure: oil tank (2), air filter (14), liquid level gauge (3), oil suction filter (22), DC motor (1), gear pump (23), check valve (24), control valve Relief valve (20), accumulator (7), ball valve (13), pressure temperature sensor (12), accumulator relief valve (18) form.

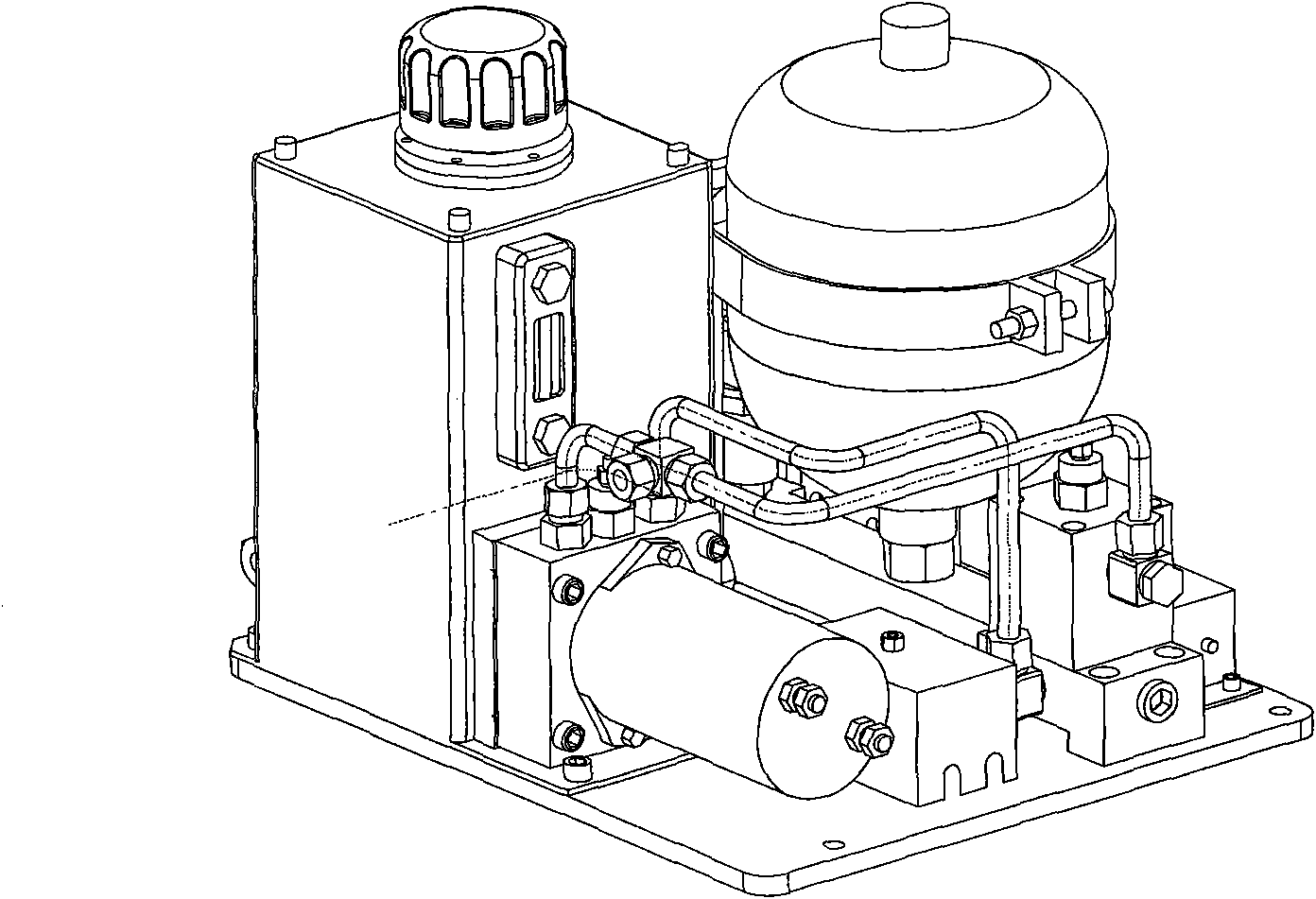

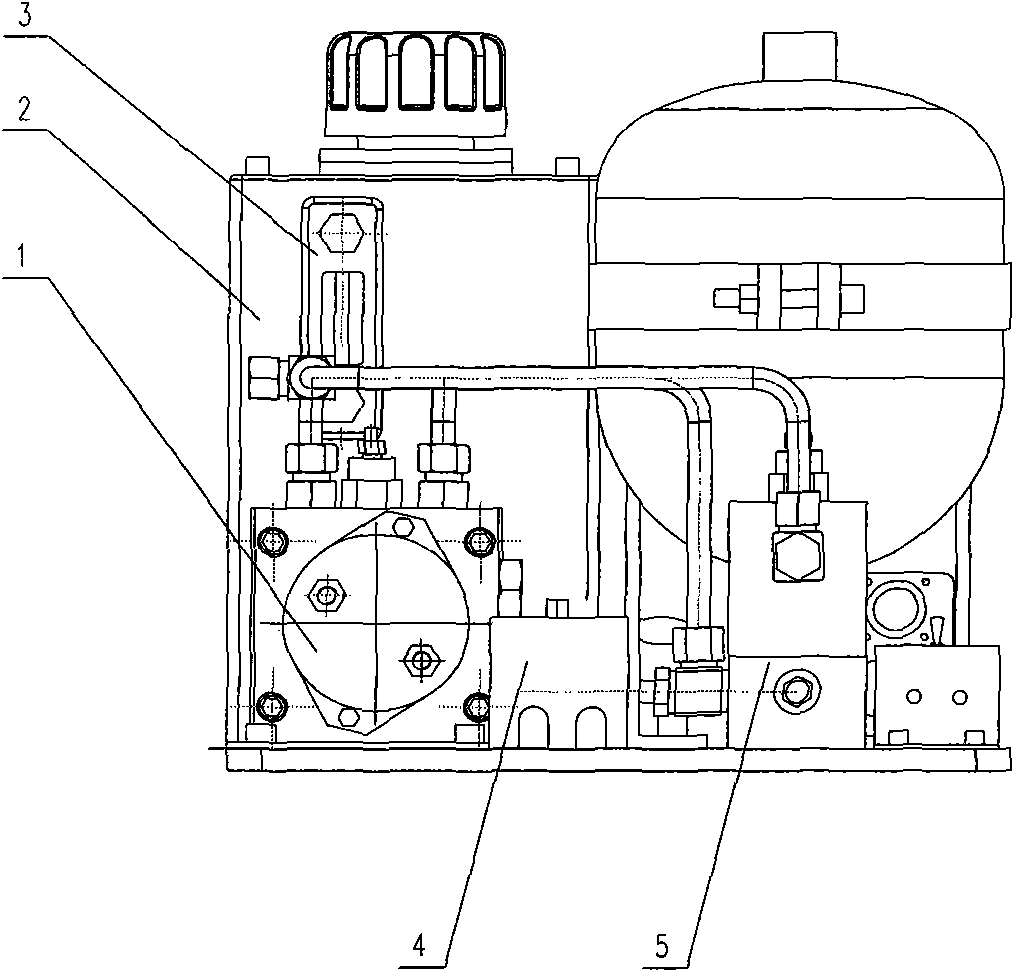

[0015] 2. Outline drawing of oil source system

[0016] Outline drawing of oil source system figure 2 , 3 , 4, and 5. It mainly includes DC motor (1), oil tank (2), liquid level gauge (3), DC relay (4), connection block (5), switch (6), accumulator (7), two-way connector of accumulator ( 8), accumulator overflow valve block (9), oil pipe (10), accumulator confinement belt (11), pressure temperature sensor (12), ball valve (13), air filter (14), bottom plate ( 15), (16), cables (17), accumulator overflow valve (18), oil pipe (19), control valve overflow valve (20), control valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com