Pipeline pressure control system of automatic speed-transformation

A technology of automatic transmission and pressure control, applied in transmission control, transmission, fluid transmission, etc., can solve the problems of reduced mileage, difficult to convey pipe pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

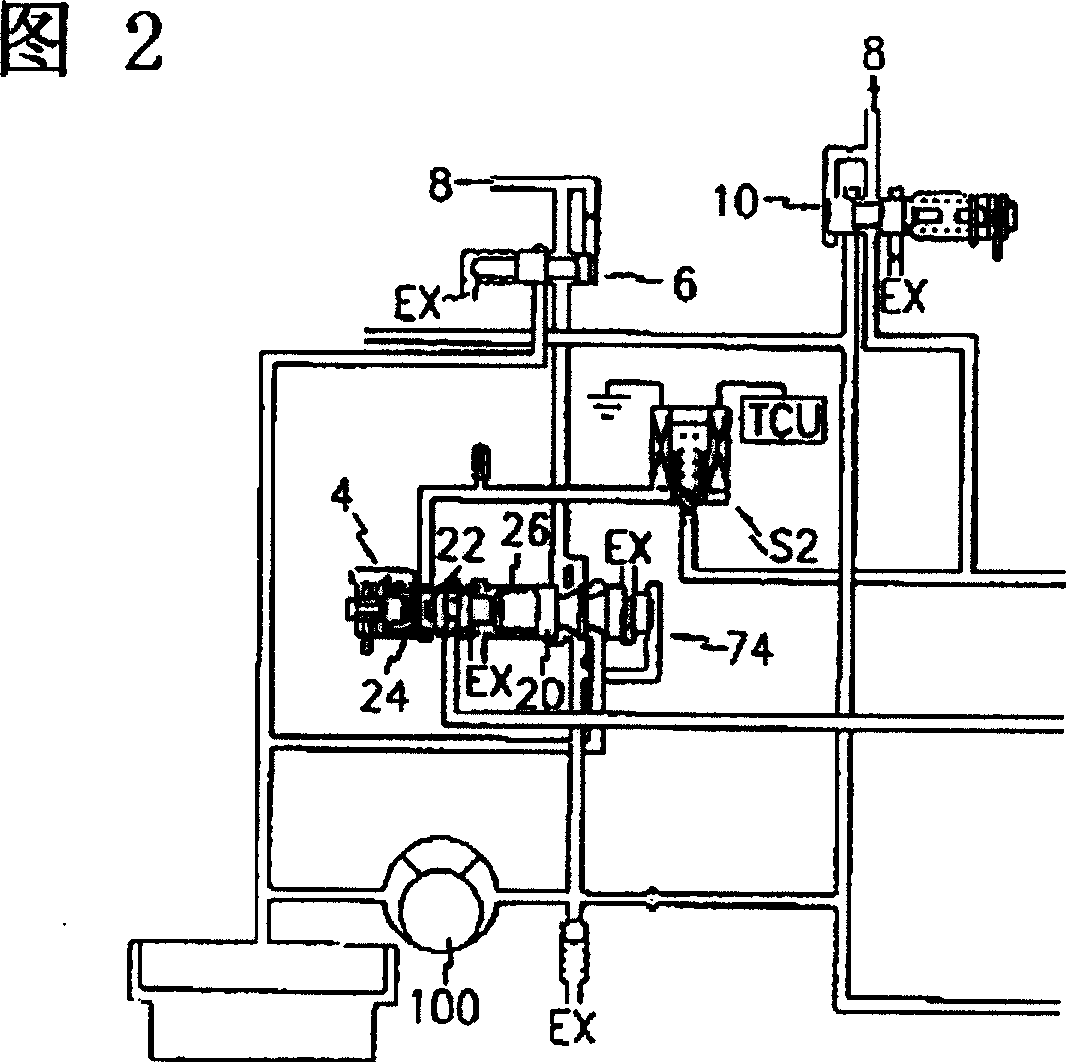

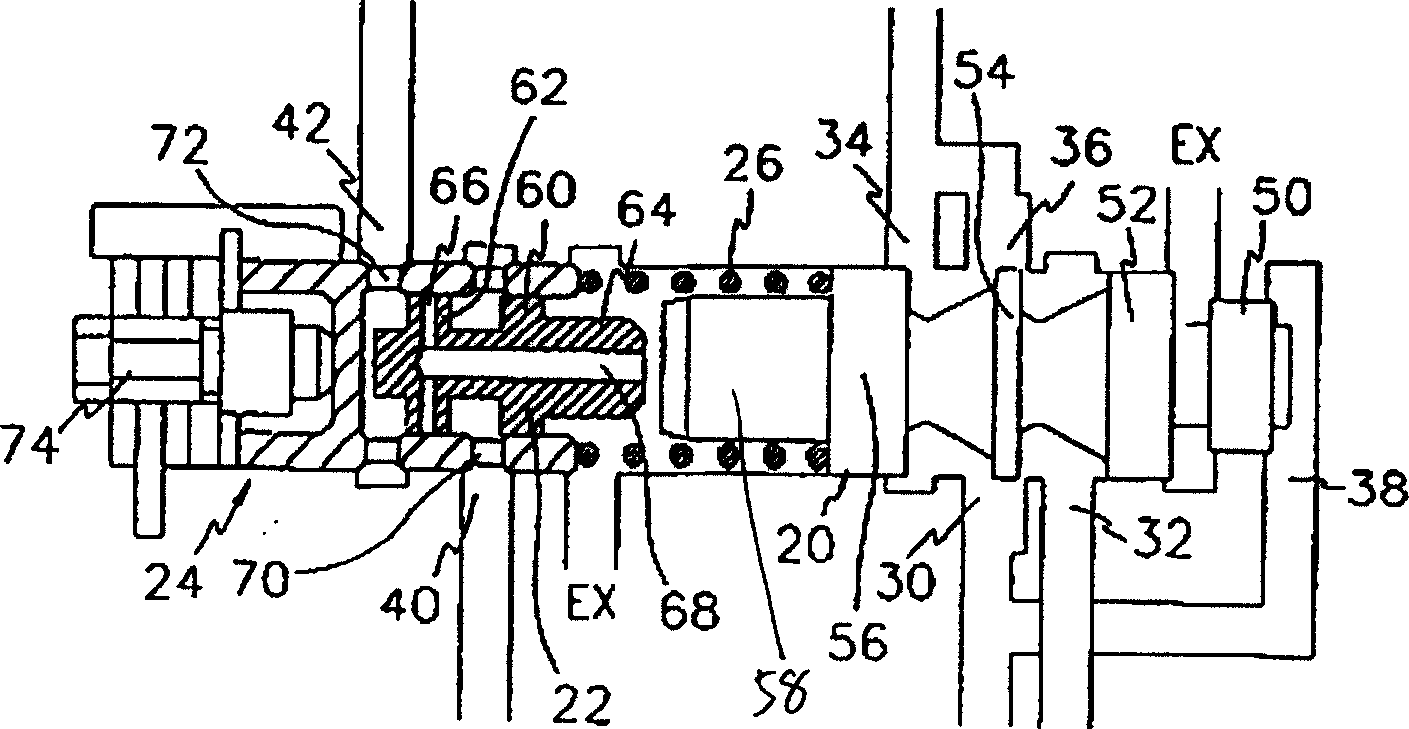

[0018] The preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

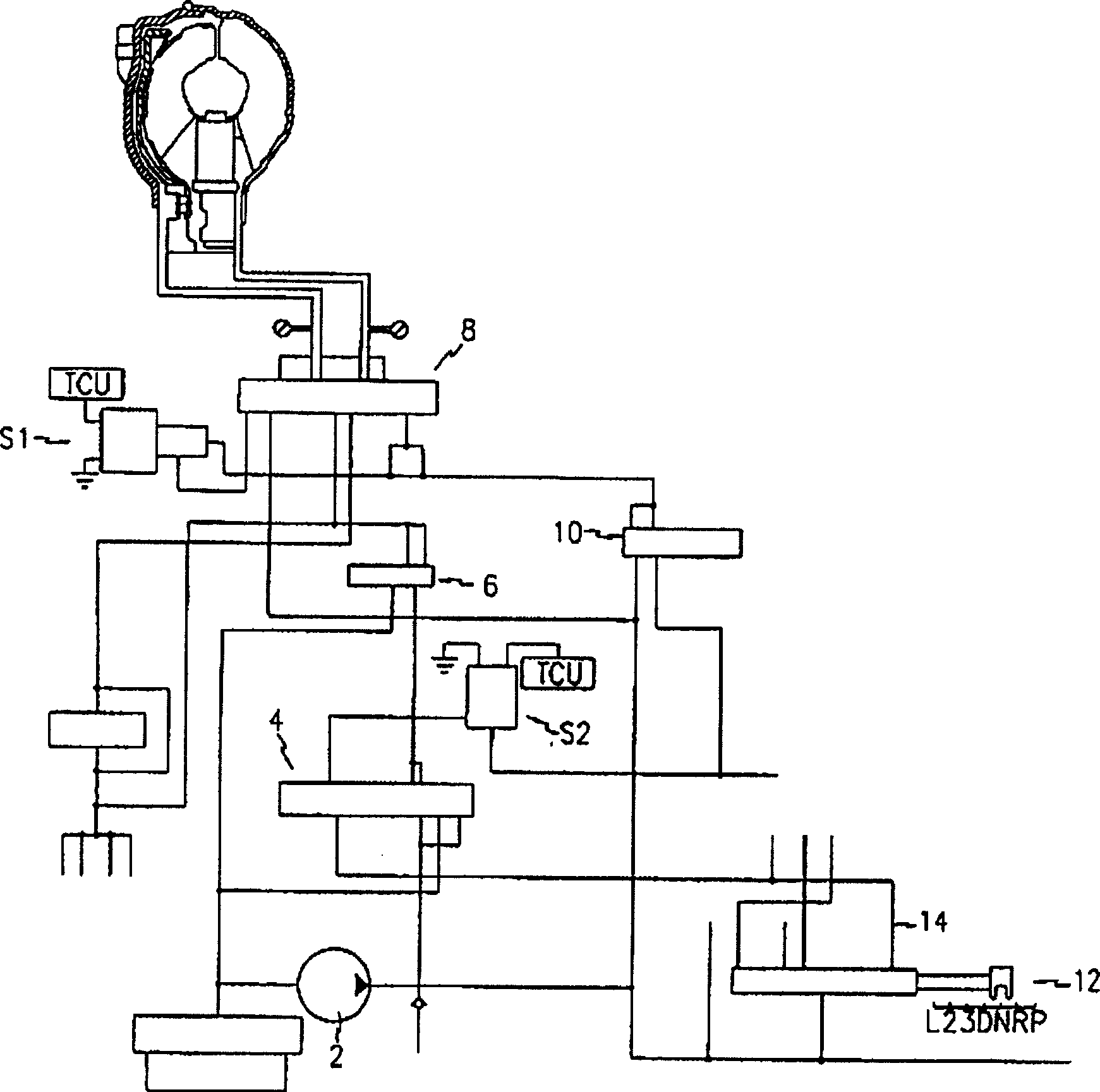

[0019] see figure 1 , the hydraulic pressure generated by the hydraulic pump 2 is adjusted through a regulating valve 4 so as to have a predetermined delivery pipe pressure. On the one hand, the regulated delivery line pressure is regulated by a torque converter control valve 6, which is then supplied to a damper clutch valve 8 under the control of the damper clutch solenoid valve S1, and on the other hand, by a pressure reducing valve 10. Partially reduce the delivery line pressure in order to supply it to the damping clutch control valve 8 or to the friction elements via the hydraulic control part and the hydraulic distribution part, which are switched by the driver actuating a manual valve 12 Its orifice, in order to lead the pressure to the required delivery pipe.

[0020] The regulating valve 4 communicates with the pressure reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com