A kind of graphene oxide reinforced titanium-based composite material and preparation method thereof

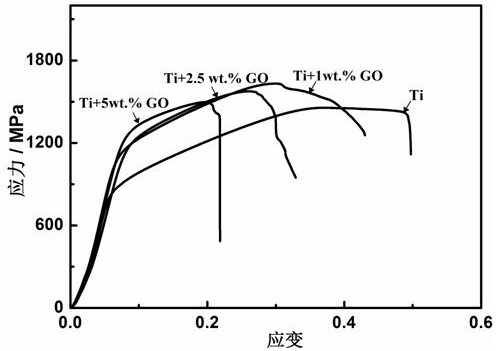

一种钛基复合材料、石墨烯的技术,应用在氧化石墨烯增强钛基复合材料及其制备领域,能够解决制约复合材料性能等问题,达到广阔工业应用前景、提升力学性能、硬度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Adopt this method invention to prepare pure titanium material, the steps are as follows:

[0023] 1) Using the improved Hummers method (see the literature Improved Synthesis of Graphene Oxide.Marcano DC, ACS NANO, 2010,4(8):4806-4814 (improved synthesis method of graphene oxide. Marcano DC, ACS NANO, 2010, Volume 4, Issue 8, Pages 4806-4814)) prepare a graphene oxide solution and dilute it with absolute ethanol to obtain a diluted graphene oxide solution;

[0024] 2) The mass ratio of the diluted graphene oxide solution to titanium powder is 0:1, and the titanium powder is dried in a vacuum oven for 12 hours;

[0025] 3) Put the obtained titanium powder into the mold of the hot-press sintering furnace, and then put it into the vacuum hot-press sintering furnace for heat preservation and pressure sintering under the protection of argon. 800 ℃, the pressure head exerted on the mold of the hot-press sintering furnace during the heat-preservation and pressure-holding sinte...

Embodiment 2

[0029] The first graphene oxide reinforced titanium-based composite material is prepared according to the following steps:

[0030] 1) The graphene oxide solution was prepared by the improved Hummers method, and diluted with absolute ethanol to obtain the diluted graphene oxide solution;

[0031] 2) Mix the graphene oxide and titanium powder contained in the above-mentioned diluted solution at a mass ratio of 0.01:1, and use an ultrasonic stirrer to ultrasonically disperse for 10 minutes to distribute the two phases evenly to obtain a mixed solution of graphene oxide and titanium powder;

[0032] 3) Put the mixed solution of graphene oxide and titanium powder in a water bath for 24 hours and stir until it is basically dry, then dry it in a vacuum oven for 12 hours to obtain a composite powder mixed with graphene oxide and titanium powder;

[0033] 4) Put the obtained composite powder into the mold of the hot-pressed sintering furnace, and then put it into the vacuum hot-presse...

Embodiment 3

[0036] The second graphene oxide reinforced titanium-based composite material is prepared according to the following steps:

[0037] 1) The graphene oxide solution was prepared by the improved Hummers method, and diluted with absolute ethanol to obtain the diluted graphene oxide solution;

[0038] 2) Mix the graphene oxide and titanium powder contained in the above diluted solution at a mass ratio of 0.025:1, and use an ultrasonic stirrer to ultrasonically disperse for 10 minutes to distribute the two phases evenly to obtain a mixed solution of graphene oxide and titanium powder;

[0039] 3) Put the mixed solution of graphene oxide and titanium powder in a water bath for 48 hours and stir until it is basically dry, then dry it in a vacuum oven for 12 hours to obtain a composite powder mixed with graphene oxide and titanium powder;

[0040] 4) Put the obtained composite powder into the mold of the hot-pressed sintering furnace, and then put it into the vacuum hot-pressed sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com