Composite phase-change material using PVA as skeleton, and preparation method thereof

A technology of composite phase change materials and skeleton materials, which is applied in the field of composite phase change materials, can solve problems such as less research, and achieve the effects of not being easily damaged, good leakage prevention performance, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

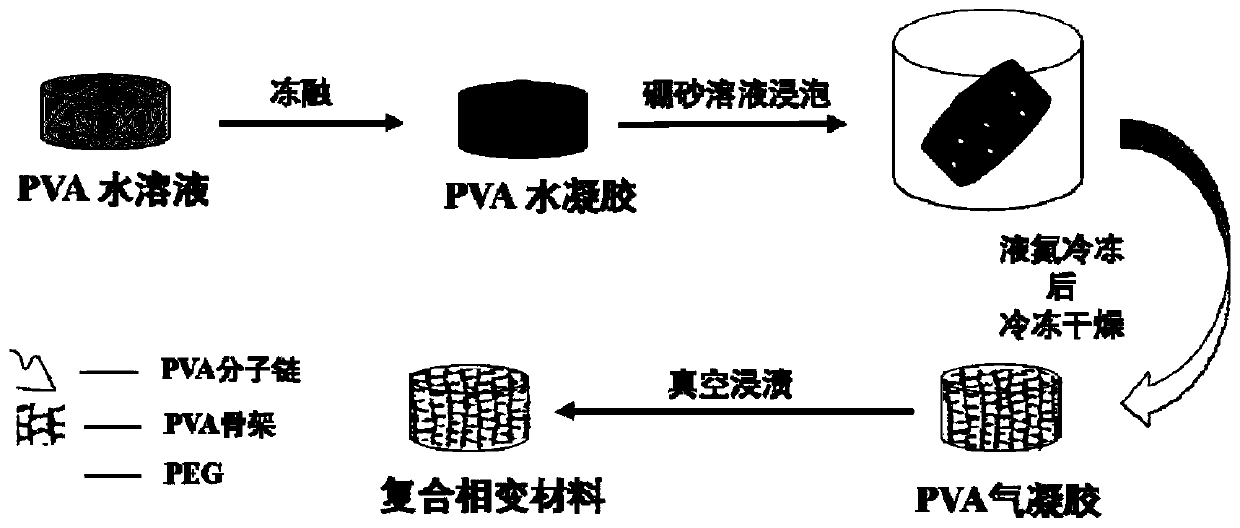

[0044] The preparation of composite phase change material comprises the following steps:

[0045] Step 1): At room temperature, add PVA (molecular weight 146000-186000) into deionized water according to 5% mass fraction, stir for 30 minutes to make it swell, then raise the temperature to 97 ° C, stir for 2 hours, and obtain a PVA aqueous solution;

[0046] Step 2): Inject the aqueous solution obtained in the above step 1 into a twelve-well plate, put it in the refrigerator to freeze for 12 hours, then take it out, and thaw it for 12 hours. One freeze-thaw cycle to get a stronger hydrogel;

[0047] Step 3): Take out the hydrogel in the above step 2 from the twelve-hole plate, put it into an aqueous solution of sodium tetraborate (the mass fraction of sodium tetraborate in the aqueous solution is 2%) and soak for 24 hours, then take it out and clean it to obtain PVA hydrogel with cross-linked structure;

[0048] Step 4): Put the hydrogel in the above step 3 in a six-well plate, ...

Embodiment 2

[0053] Step): At room temperature, add PVA (molecular weight 146000-186000) into deionized water according to 5% mass ratio, stir for 30 minutes to make it swell, then raise the temperature to 97° C., and stir for 2 hours to obtain a PVA aqueous solution;

[0054] Step 2): Inject the aqueous solution obtained in the above step 1 into a twelve-well plate, put it in the refrigerator to freeze for 12 hours, then take it out, and thaw it for 12 hours. One freeze-thaw cycle to get a stronger hydrogel;

[0055] Step 3): Take out the hydrogel in the above step 2 from the twelve-hole plate, put it into an aqueous solution of sodium tetraborate (the mass fraction of sodium tetraborate in the aqueous solution is 2%) and soak for 24 hours, then take it out and clean it to obtain PVA hydrogel with cross-linked structure;

[0056] Step 4): Put the hydrogel in the above step 3 in a six-well plate, inject a certain amount of deionized water to completely immerse the PVA hydrogel, and then f...

Embodiment 3

[0061] Step): At room temperature, add PVA (molecular weight 146000-186000) into deionized water according to 5% mass ratio, stir for 30 minutes to make it swell, then raise the temperature to 97° C., and stir for 2 hours to obtain a PVA aqueous solution;

[0062] Step 2): Inject the aqueous solution obtained in the above step 1 into a twelve-well plate, put it in the refrigerator to freeze for 12 hours, then take it out, and thaw it for 12 hours. One freeze-thaw cycle to get a stronger hydrogel;

[0063] Step 3): Take out the hydrogel in the above step 2 from the twelve-hole plate, put it into an aqueous solution of sodium tetraborate (the mass fraction of sodium tetraborate in the aqueous solution is 2%) and soak for 24 hours, then take it out and clean it to obtain PVA hydrogel with cross-linked structure;

[0064] Step 4): Put the hydrogel in the above step 3 in a six-well plate, inject a certain amount of deionized water to completely immerse the PVA hydrogel, and then f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com