High-precision pressure measuring system with variable reference pressure

A technology of reference pressure and measurement system, applied in pressure difference measurement between multiple valves, measurement device, measurement of fluid pressure, etc., can solve problems such as slow response speed, unsuitable for measuring pressure parameters, etc. Solve the effect of low measurement accuracy and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

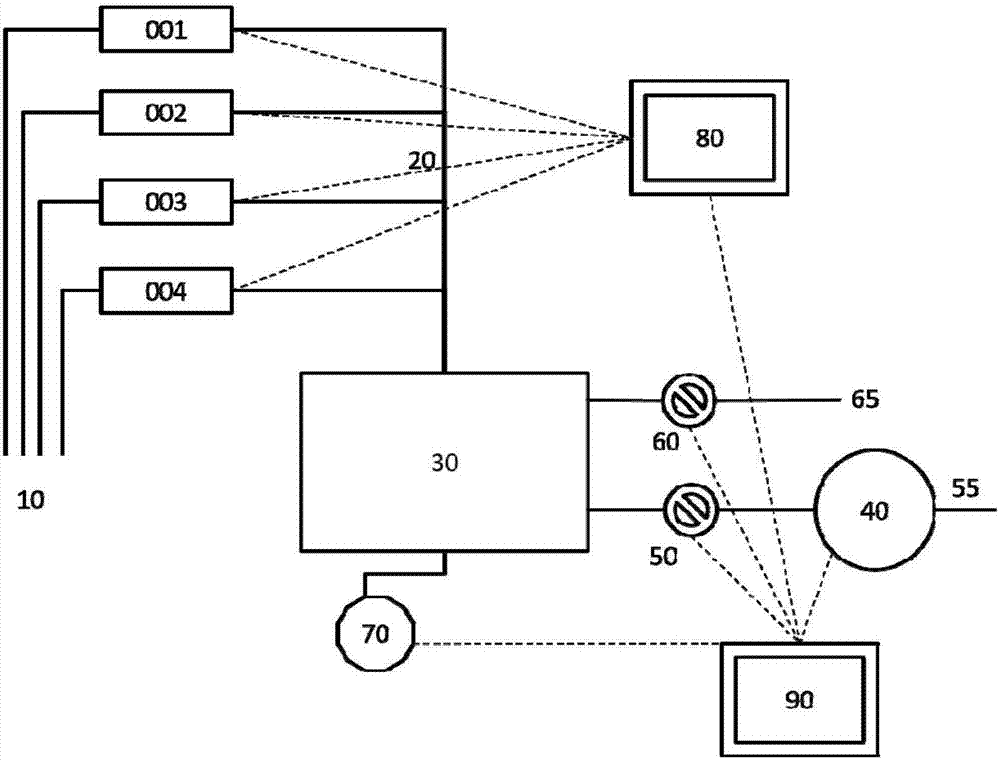

[0050] Such as figure 1 As shown, the variable reference pressure high-precision pressure measurement system of the present invention includes several differential pressure sensors 001-004, a flow field air-inducing pipe 10, a reference pressure air-inducing pipe 20, a reference pressure chamber 30, a pressure regulating pump 40, and a regulating Pump cut-off valve 50, regulating pump exhaust pipe 55, pressure chamber exhaust valve 60, pressure chamber exhaust pipe 65, high-precision pressure gauge 70, data acquisition equipment 80, control equipment 90, etc.

[0051] The number and parameters of differential pressure sensors 001-004 can be adjusted according to actual needs. Each differential pressure sensor includes a measurement air hole and a reference pressure air hole. The two air holes are respectively connected to the flow field air pipe 10 and the reference pressure air hole. In the air pipe 20 , the pressure measured by each differential pressure sensor 001 to 004 is...

Embodiment 2

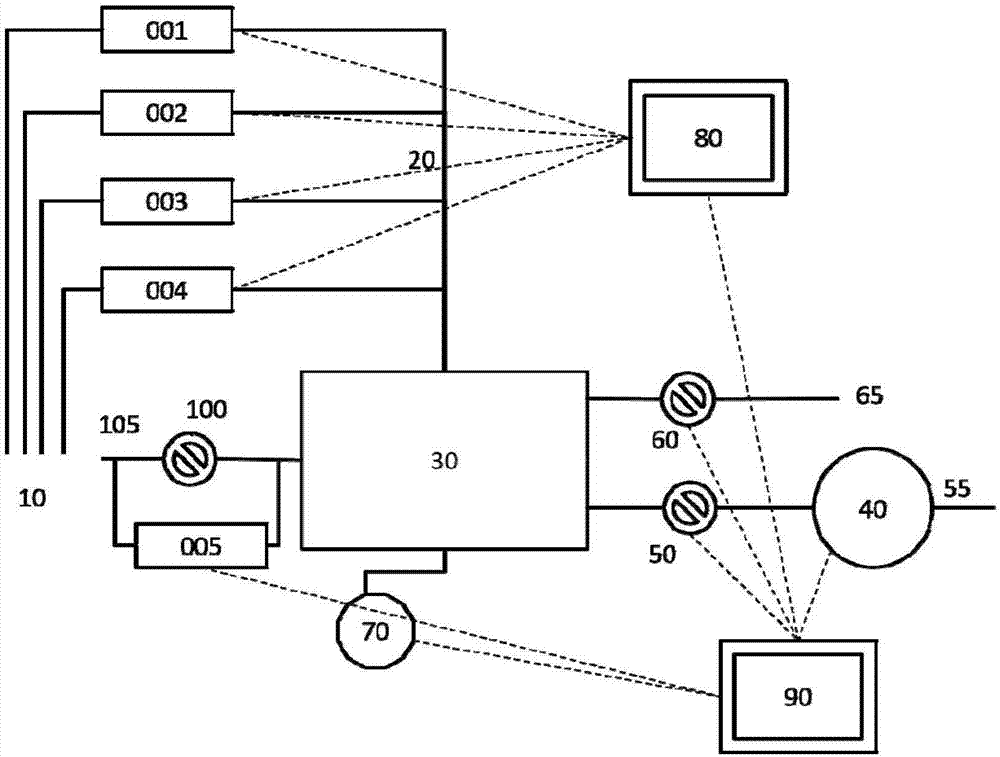

[0062] figure 1 In the implementation example 1, the pressure P in the reference pressure chamber ref The value of is preset through the control device 90. In actual operation, the following unfavorable situations may be encountered:

[0063] (1) There is a deviation between the wind tunnel operating parameters and the preset value, which will cause the dP to be too large, resulting in a high absolute measurement error of dP, resulting in a decrease in the overall measurement accuracy, and may also exceed the measurement range of the differential pressure sensor;

[0064] (2) The wind tunnel continuously blows multiple working conditions, but the pumps, valves and other components of the present invention have a relatively large operation delay, and the reference pressure adjustment time is relatively long, resulting in having to prolong the operation time of the wind tunnel, thereby increasing the cost of the experiment.

[0065] Such as figure 2 As shown, this embodiment ...

Embodiment 3

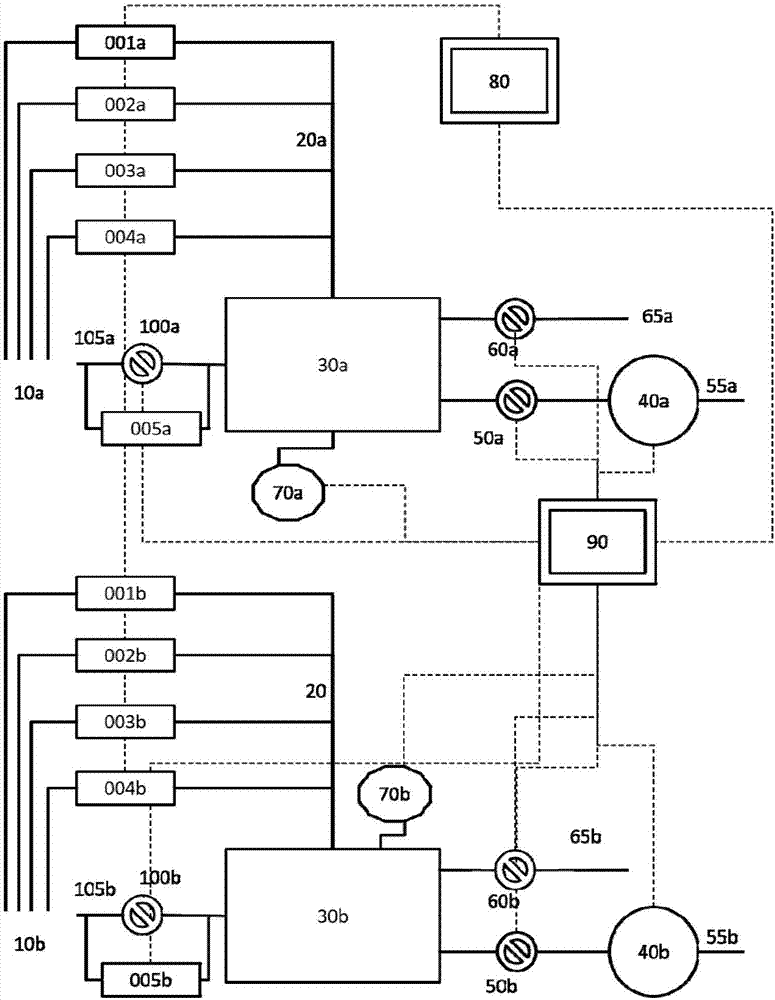

[0068] In order to measure the pressure distribution at different sections of the wind tunnel flow field at the same time, for example, in a compressor experiment, it is necessary to measure the pressure distribution of the inlet and outlet sections of the compressor at the same time, multiple reference pressure chambers can be set. Combine now image 3 and Figure 4 Describe the application of the scheme with two reference pressure chambers in a certain compressor experiment.

[0069] During the experimental test of the aerodynamic performance of the compressor, it is necessary to measure the pressure distribution of the inlet and outlet sections of the compressor respectively, and the layout of the main measuring points can be seen Figure 4 The inlet pressure probe P1 and the outlet pressure probe P2 are shown, these two types of probes correspond to the total inlet pressure P of the compressor respectively. 1t / static pressure P 1s and total compressor outlet pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com