Digital temperature compensation system and method

A technology of digital temperature compensation and temperature compensation, which is applied in measuring devices, instruments, measuring fluid pressure, etc., can solve the problem of low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

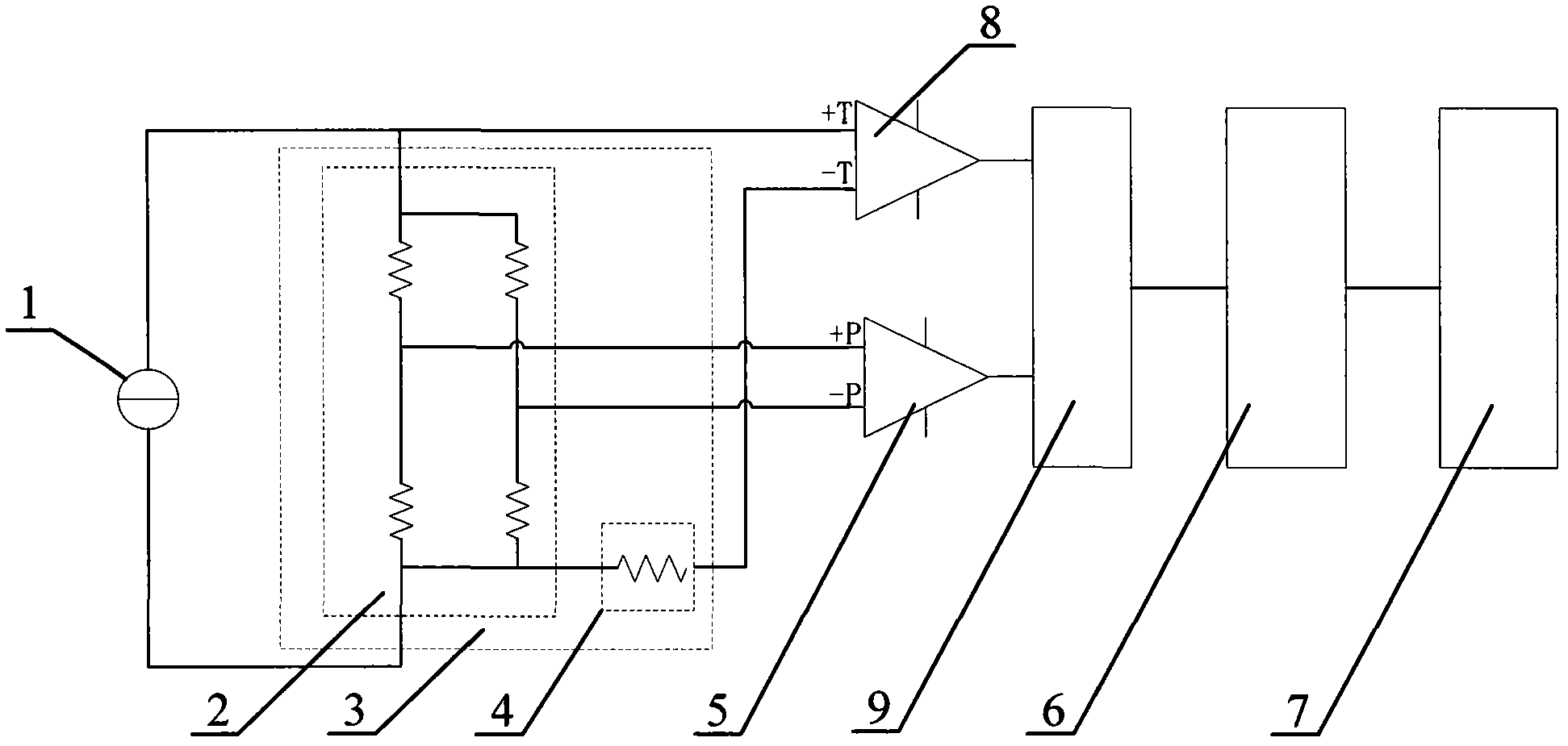

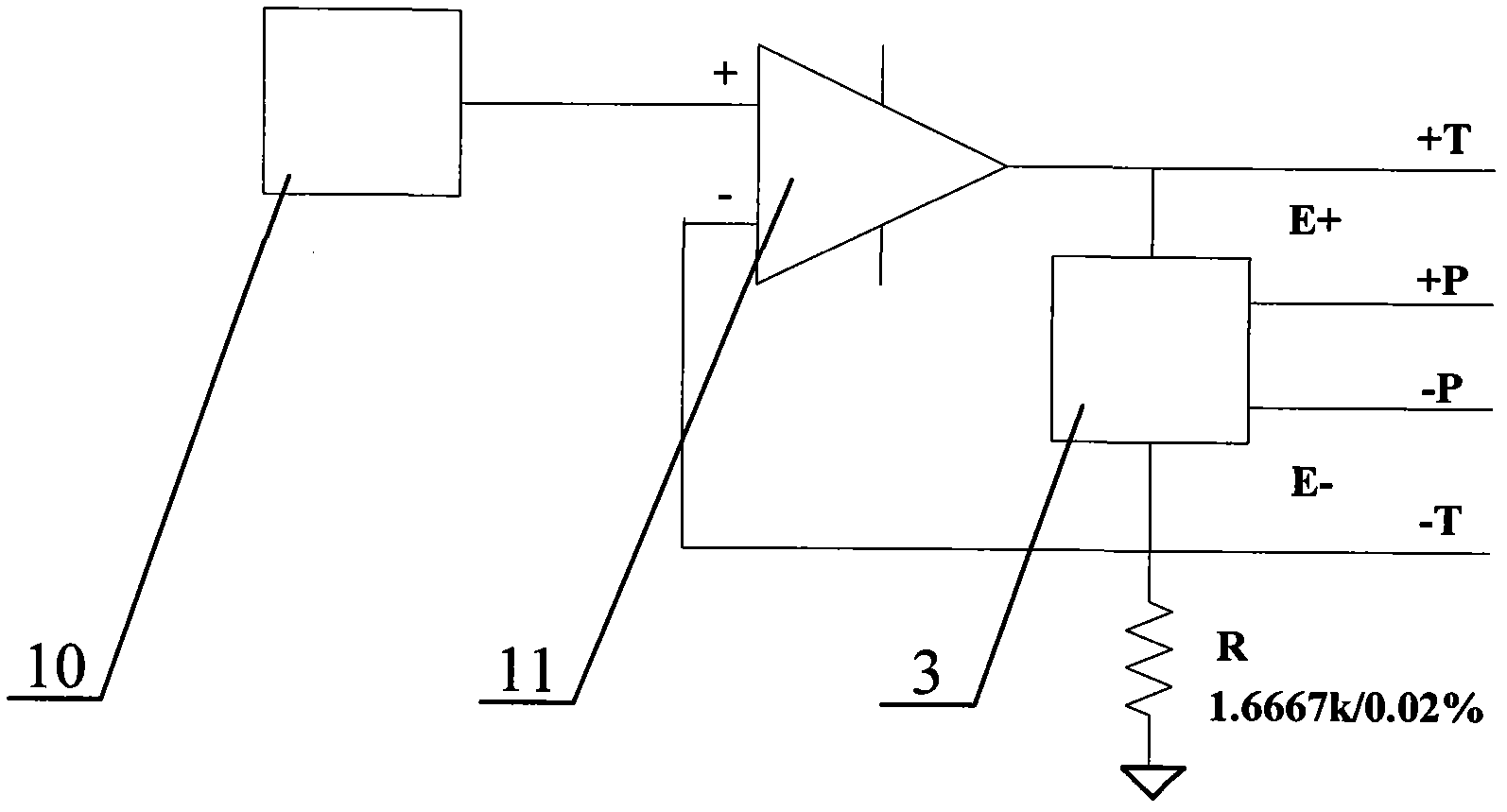

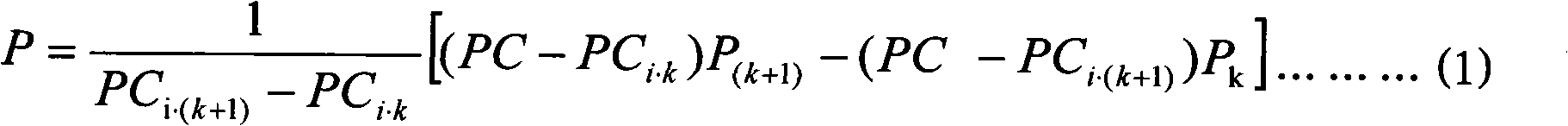

[0041] A digital temperature compensation system, the pressure sensor 2 is a pressure sensor with a range of ±30kPa, and the excitation current required by the selected pressure sensor 2 is 1.5mA. The constant current source 1 of this system is composed of a reference voltage source 10 and an OP400 chip 11, wherein the reference voltage source 10 adopts a MAX6225AESA chip and is connected with the OP400 chip 11 to provide a 2.5V reference voltage for the OP400 chip 11; the OP400 chip 11 is connected to the pressure sensor The module 3 is connected, and the reference voltage is converted into a reference current to provide a 1.5mA excitation current for the pressure sensor module 3 . The current conversion resistance R is 1.6667KΩ. The pressure signal amplifier 5 adopts AD620 to realize the differential output of 1:100. Temperature signal amplifier 8 adopts AD620 to realize 1:1 differential output. Multiplexing switch 9 adopts MAX307 to realize channel selection of temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com