A dual temperature compensation refrigerator and a method for realizing dual temperature compensation

A technology of temperature compensation and dual temperature, which is applied in household refrigerators, coolers, lighting and heating equipment, etc., can solve the problems that the thermostat cannot be started, and the body of the thermostat cannot be guaranteed, so as to prevent the phenomenon of temperature rise and ensure Normal startup and automatic temperature compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

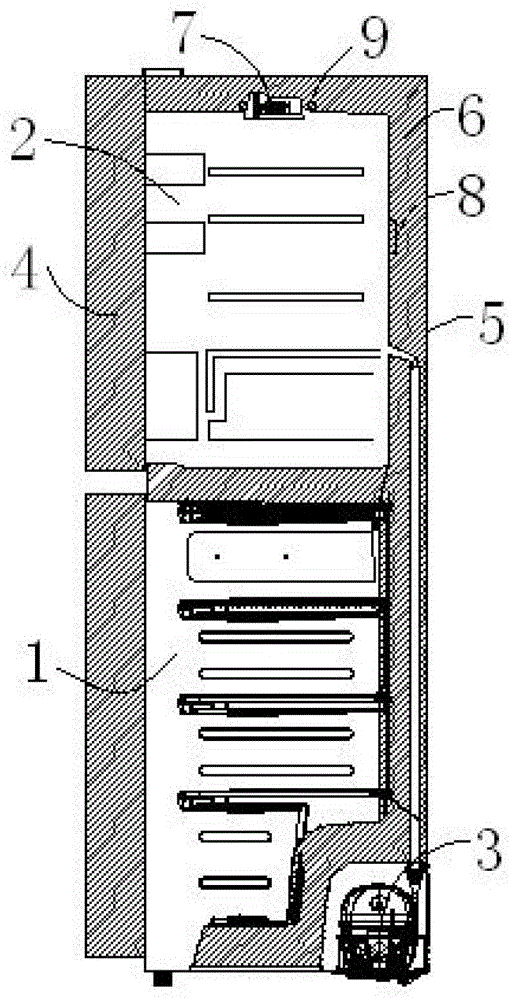

[0028] like figure 1 Shown is a side sectional view of a double temperature compensation refrigerator.

[0029] A refrigerator with dual temperature compensation, comprising a freezer 1, a freezer 2, a compressor 3, a door 4, an outer shell 5 and a dual temperature compensation system, the interior of the door 4, the freezer 1 and the outer shell 5 A foam interlayer 6 is provided between the refrigerating chamber 2 and the outer casing 1, an evaporator is arranged on the periphery of the refrigerating chamber 2, and a warming Controller body 7.

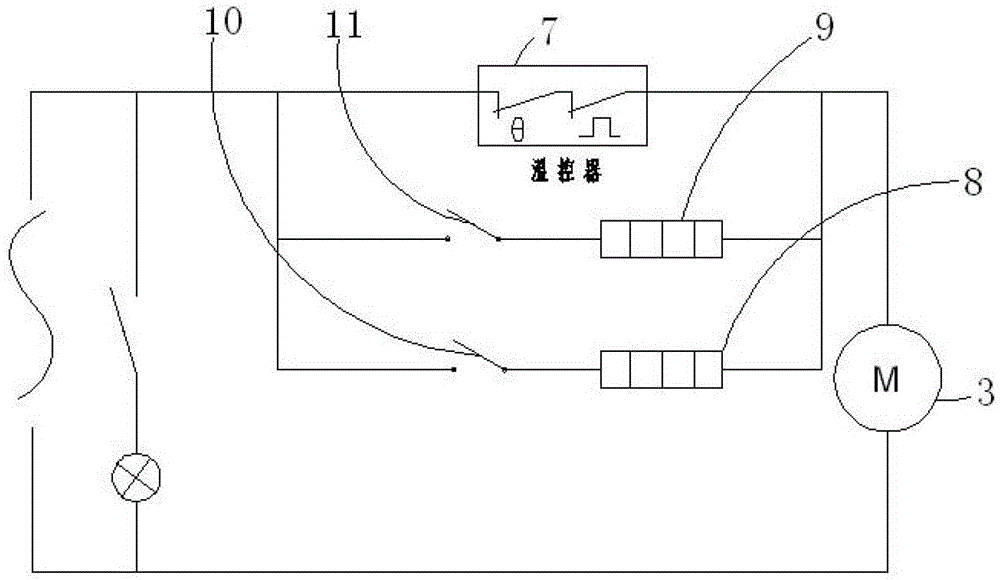

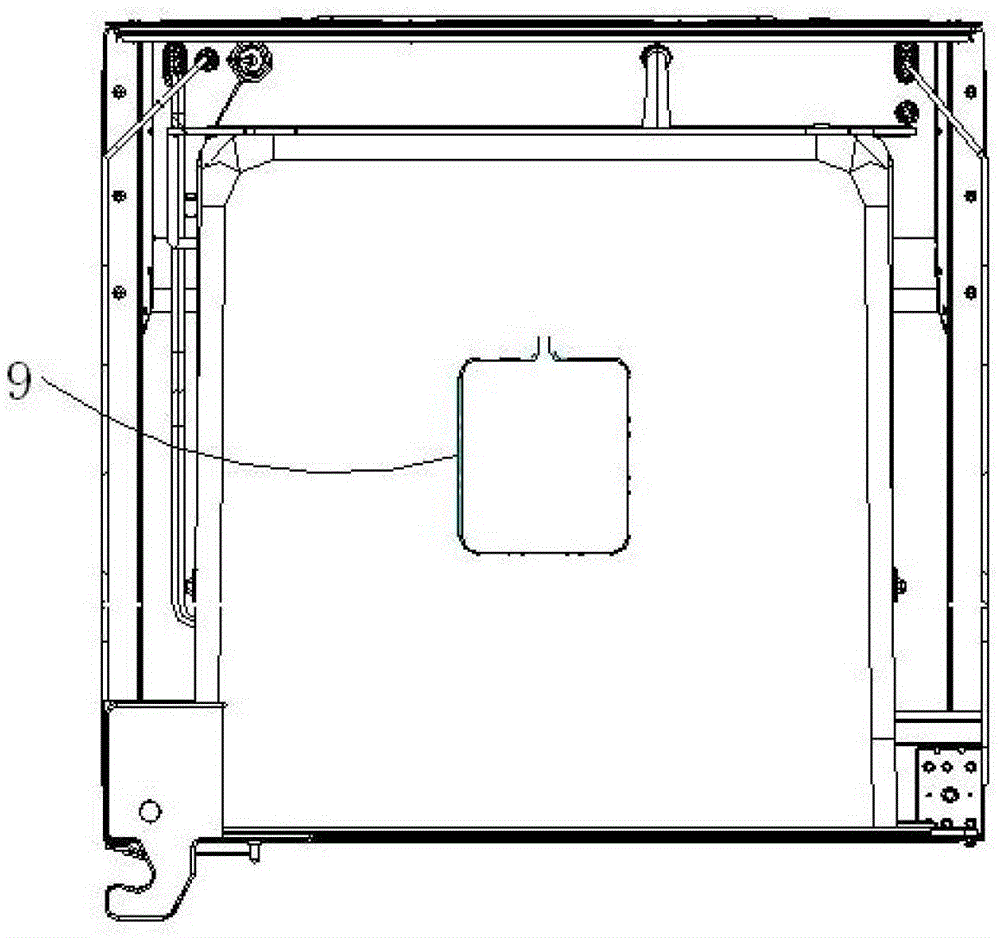

[0030] The dual temperature compensation system includes a first temperature compensation heater 8 and a second temperature compensation heater 9, the first temperature compensation heater 8 is located in the foam interlayer 6 on one side of the evaporato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com