Wide-range high-precision double film-integrated capacitive pressure sensor and manufacturing method

A pressure sensor, high-precision technology, applied in the direction of measuring force, instruments, measuring devices, etc., can solve the problems of limiting the application range of sensors, solve the problem of overload protection, easily ensure the accuracy, and improve the effect of pressure measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

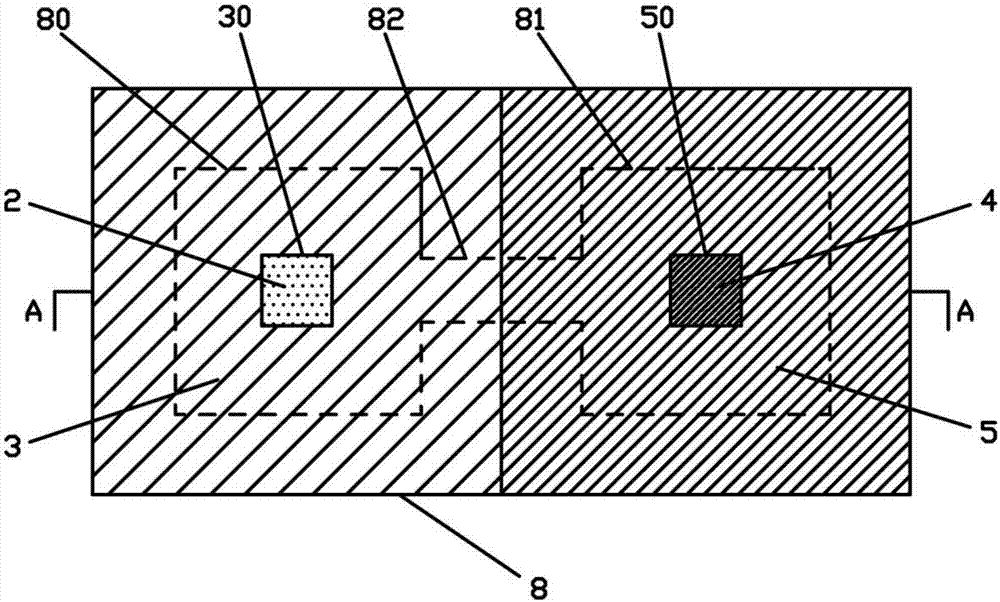

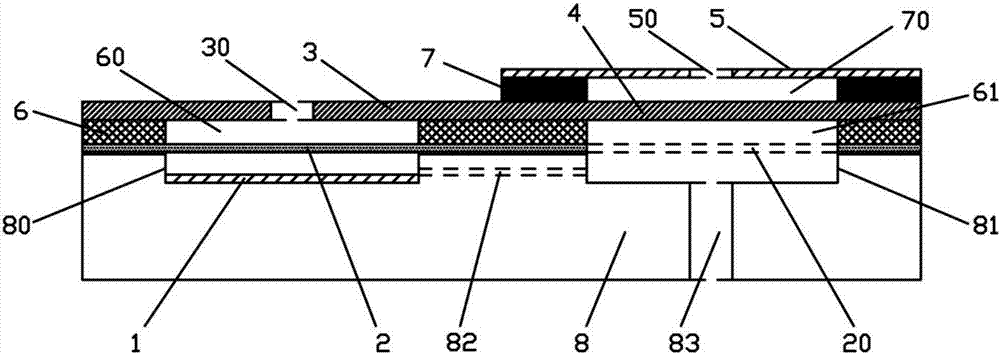

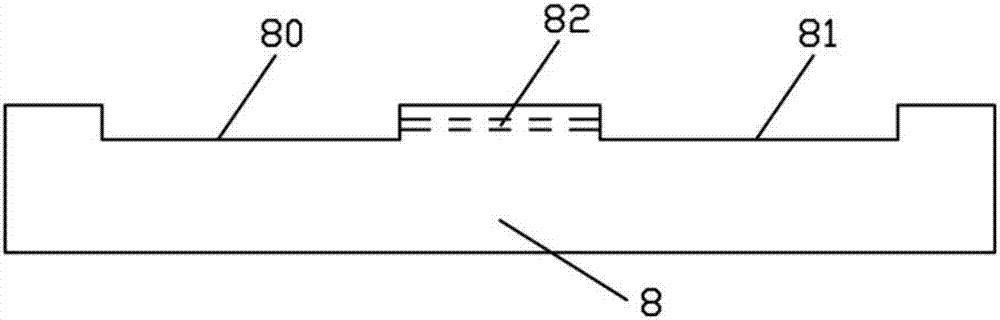

[0028] Such as figure 1 with figure 2 As shown, a wide range and high precision integrated double-membrane capacitive pressure sensor described in the present invention includes a glass substrate 8, and the glass substrate 8 is provided with shallow groove one 80 and shallow groove two 81, shallow groove one 80 and shallow groove two. Groove 2 81 is communicated with through thin groove 82, shallow groove 2 81 center position is provided with shallow groove through hole 83, shallow groove through hole 83 extends from shallow groove 2 81 bottom surface to glass substrate 8 bottom surface, shallow groove 1 80 is provided with measurable Capacitor C1 with low pressure difference, shallow groove 2 81 is equipped with capacitor C2 that can measure high pressure difference, capacitor C1 that can measure low pressure difference includes bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com