Transparent nozzle self-circulation device for internal cavity flowing visualization research

A technology of cavitation flow and nozzles, which is applied in the field of self-circulation devices, can solve problems such as leakage, and achieve the effects of high measurement accuracy, easy implementation, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

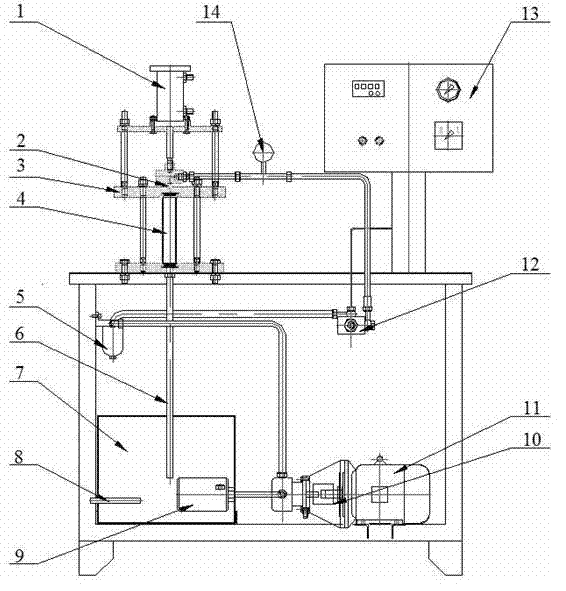

[0019] The structure of the self-circulation device for the visualization research of cavitation flow inside a transparent nozzle of the present invention is as follows: figure 1 As shown, including oil circuit system, transmission system and monitoring system.

[0020] The oil circuit system is used to ensure the self-circulation flow of fuel oil. The oil circuit system includes a fuel tank 7, a coarse filter 9, a fine filter 5, an oil pressure regulating valve 12, a nozzle 2, a measuring cylinder 4, The oil return pipe 6 and the fuel tank 7 are provided with a heater 8 for opening and closing according to the needs of the test. The fuel is extracted from the fuel tank 7 and heated to the temperature required by the test by the heater 8, then passes through the coarse filter 9 and the fine filter. 5. Oil pressure regulating valve 12, nozzle 2, measuring cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com