Spring performance automatic testing device

An automatic testing device and performance technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as large errors, poor repeatability, and inability to improve machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

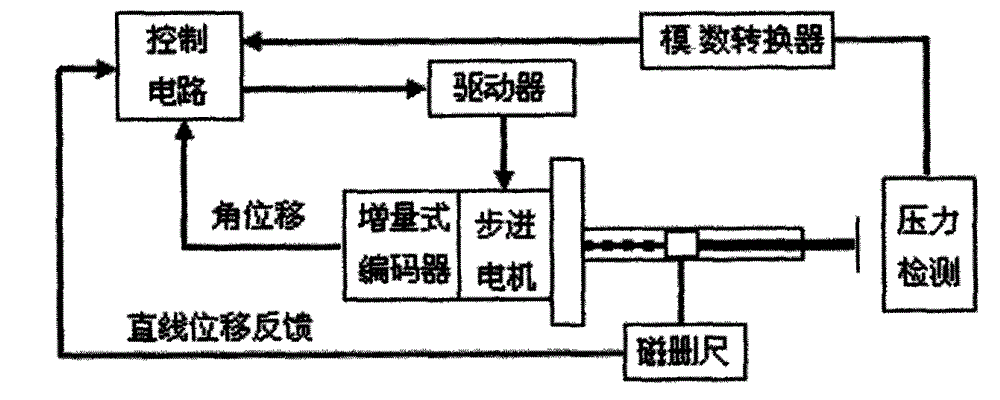

[0009] Such as figure 1 As shown, the displacement measurement control strategy of the detector adopts double closed-loop control. The inner loop is an incremental encoder to detect angular displacement, which is used to eliminate the error caused by the stepping motor out of step. The outer loop is a magnetic grid to detect linear displacement, which is used to eliminate The error caused by the guide rail screw clearance and mechanical transmission. The inner ring realizes fast position calibration, and the outer ring corrects repeatability errors.

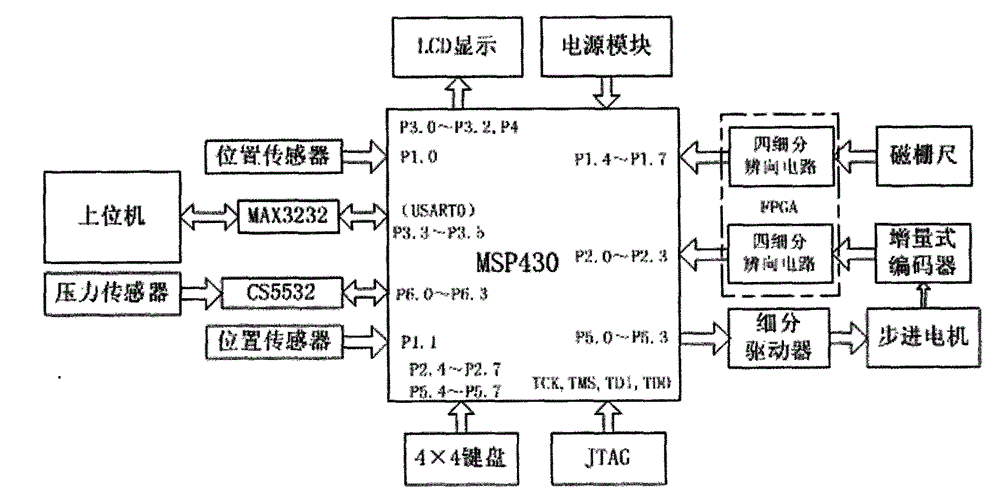

[0010] Such as figure 2 As shown, the main control unit adopts 16-bit low-power microcontroller MSP430 of TI Company to control the stepper motor driver, and the stepper motor is a two-phase hybrid stepper motor. The incremental encoder in the inner loop detection circuit is tightly mounted on the drive shaft of the stepper motor, and the four-fold pulse data corresponding to the angular displacement is sent to the main contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com