Optimal setting method for roll force of six-roller temper mill unit

A technology for optimizing setting and rolling force, applied in the direction of rolling force/roll gap control, etc., which can solve the problems of large error of rolling force setting value, influence of shape, sharp fluctuation of rolling force and elongation, etc. , to improve the yield, reduce production instability, and improve the stability of shape control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

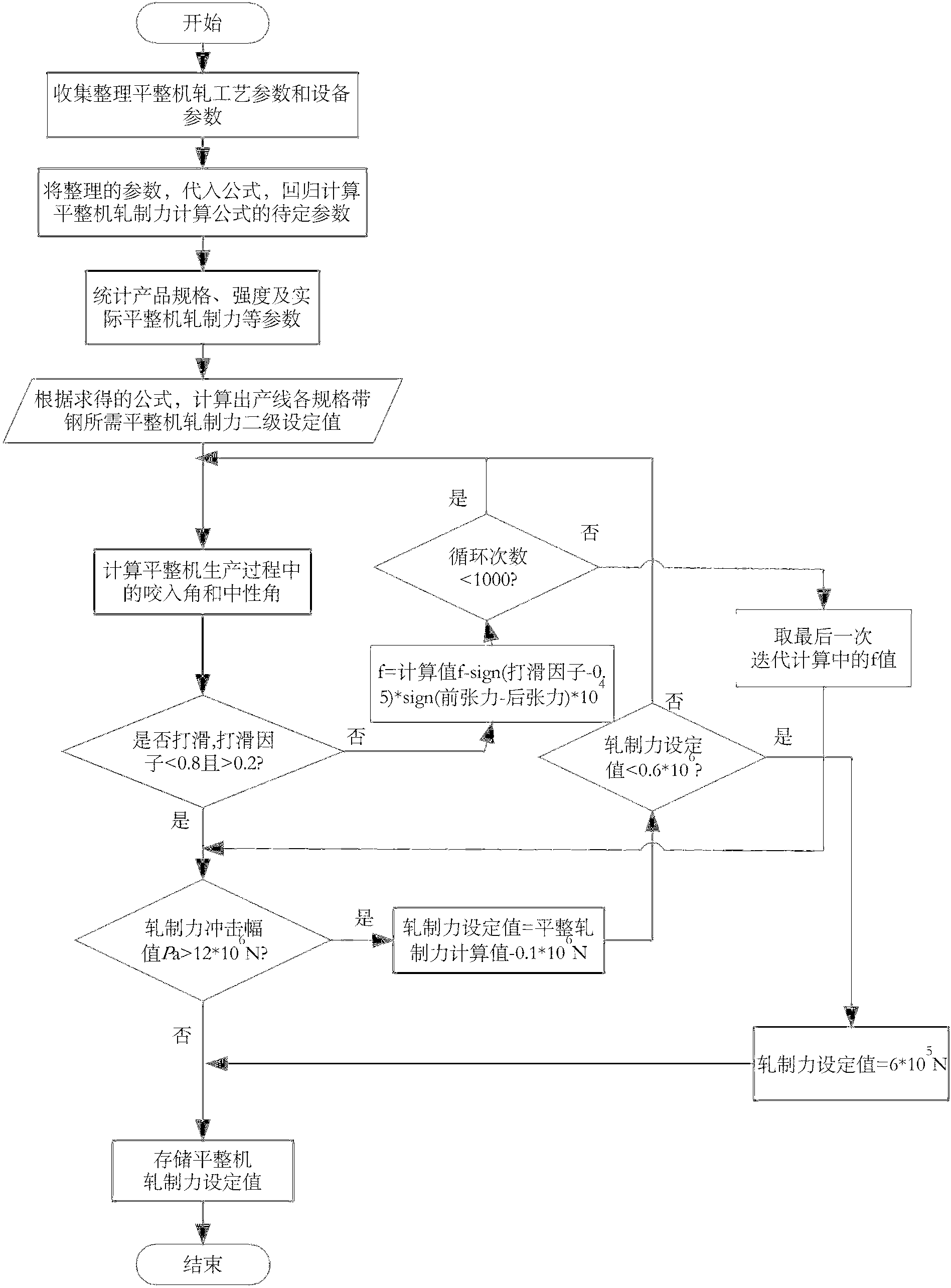

[0027] In order to illustrate the basic idea of the present invention, a certain 1850 six-roll skin pass unit is taken as an example, with the help of figure 1 To describe the tension optimization setting process of the steel strip with the specification of 1.2m*1.0mm and the steel type of SPCC on a specific skin pass unit.

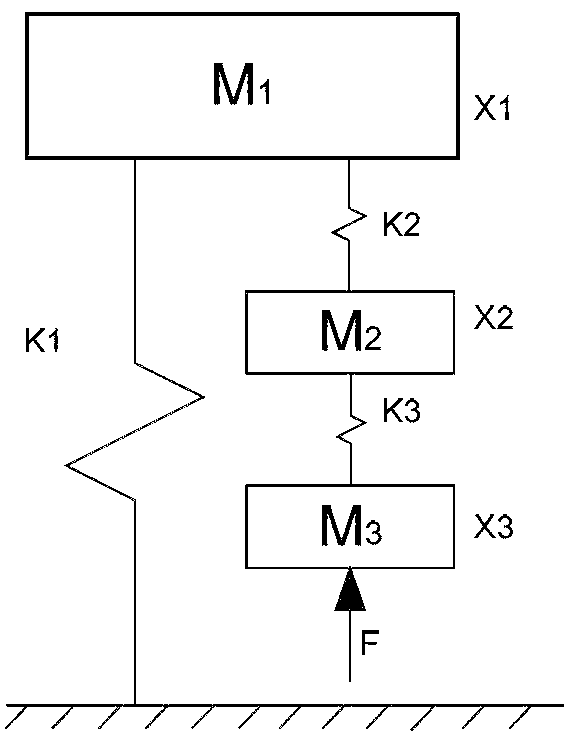

[0028] First, collect the equipment and process parameters of the skin pass unit in step 1, and collect the equipment and process parameters of the skin pass unit in step 1, including the diameter of the work roll 550mm, the equivalent mass of the backup roll, intermediate roll and work roll 5.4*10 4 kg, 7.02*10 3 kg, 4.71*10 3 kg, the equivalent stiffness of the leveling machine archway is 7.5*10 10 N / m, contact stiffness between backup roll and intermediate roll 1.0*10 10 N / m, contact stiffness between work roll and intermediate roll 0.5*10 10 N / m, the maximum rolling pressure 12*10 6 N, minimum rolling pressure 6*10 5 N, go to step 2;

[0029]...

Embodiment 2

[0042] In order to further clarify the design idea of the patent, a certain 1850 six-roll skin pass unit is taken as an example, with the help of figure 1 To describe the tension optimization setting process of the steel strip with the specification of 1.7m*0.65mm and steel type Trip780 on a specific skin pass unit.

[0043] First, collect the equipment and process parameters of the skin pass unit in step 1, and collect the equipment and process parameters of the skin pass unit in step 1, including the diameter of the work roll 550mm, the equivalent mass of the backup roll, intermediate roll and work roll 5.4*10 4 kg, 7.02*10 3 kg, 4.71*10 3 kg, the equivalent stiffness of the leveling machine archway is 7.5*10 10 N / m, contact stiffness between backup roll and intermediate roll 1.0*10 10 N / m, contact stiffness between work roll and intermediate roll 0.5*10 10 N / m, the maximum rolling pressure 12*10 6 N, minimum rolling pressure 0.6*10 6 N, go to step 2;

[0044] In st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com