Non-intrusive pressure detection method and measurement system based on time delay intervals of adjacent longitudinal waves

A detection method, non-invasive technology, applied in the direction of fluid pressure measurement using acoustic methods, etc., can solve the problems of the influence of transit time on working characteristics, reduce the service life of containers, and cannot be completely eliminated, so as to overcome the ultrasonic transit time measurement Error, the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

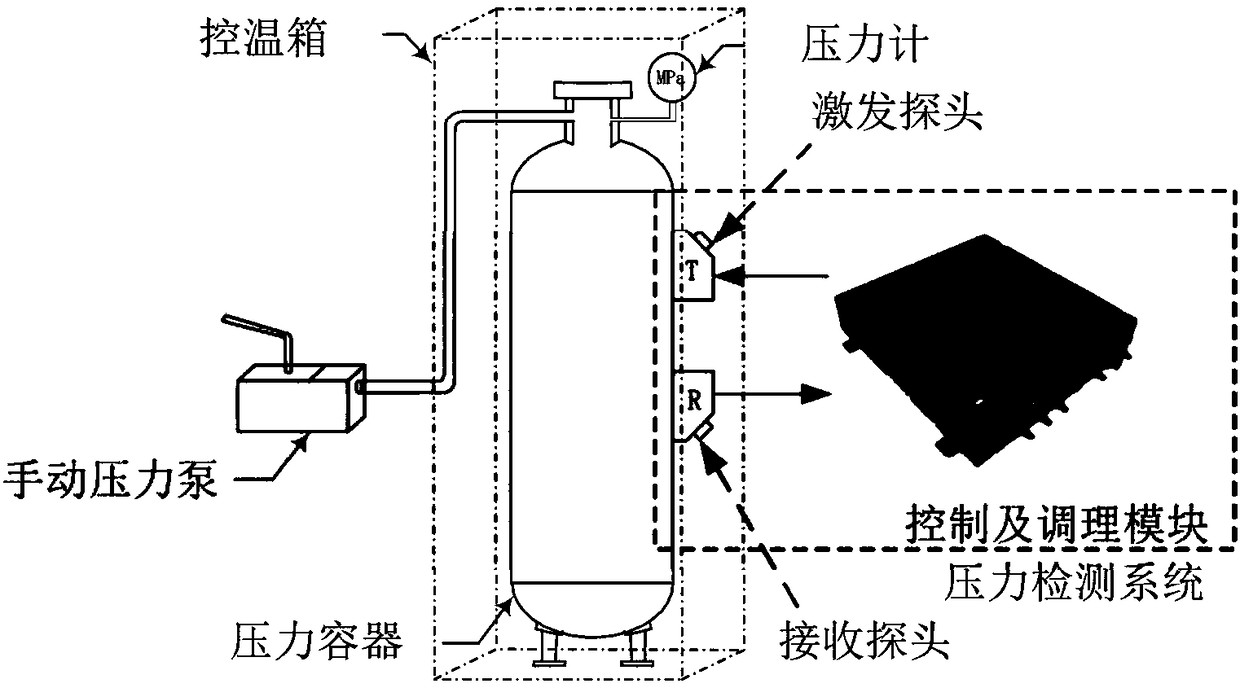

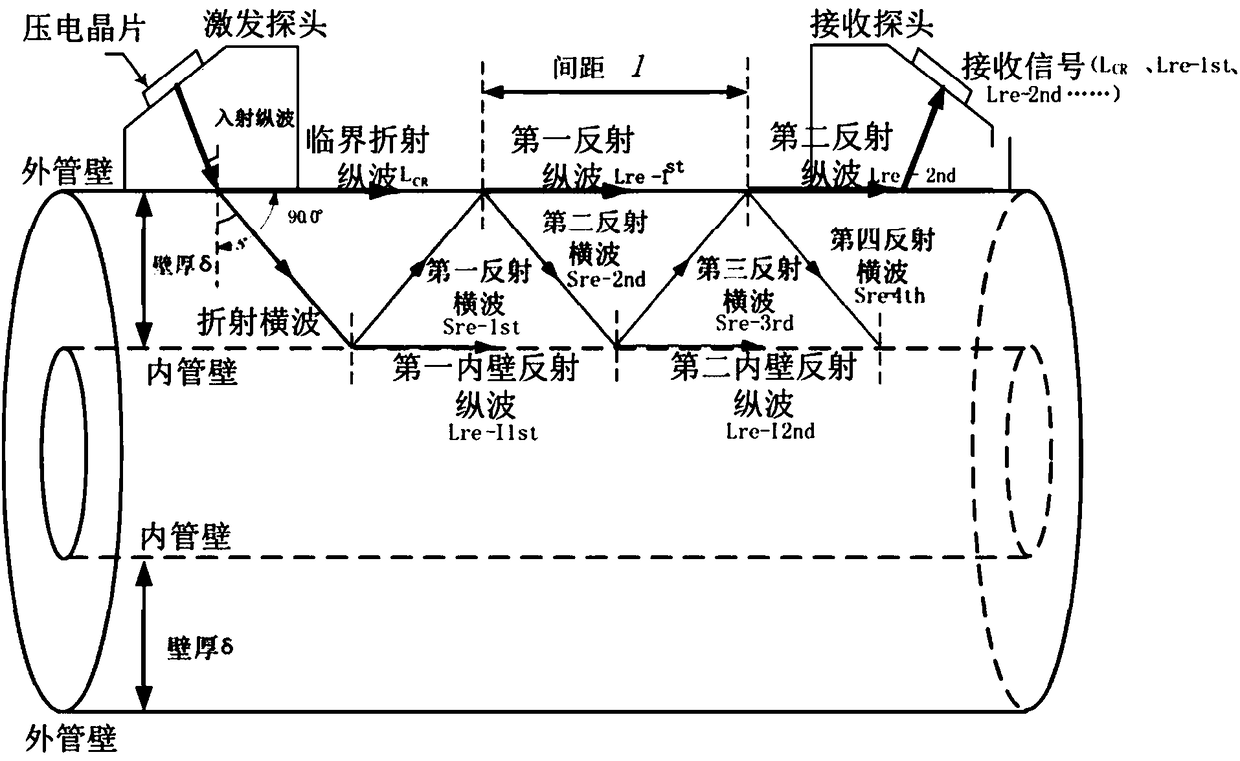

[0054] In this embodiment, the pressure detection device based on the time delay interval between adjacent longitudinal waves to realize the method of the present invention is as follows: figure 1 shown. The device includes: a cylindrical pressure vessel, a manual pressure test pump, a constant temperature box, and a pressure detection system. The pressure detection system includes a control and conditioning module, an ultrasonic transmitting probe and a receiving probe. The manual pressure test pump is equipped with a digital pressure gauge, which adjusts the pressure in the container through hydraulic control; the pressure container is placed in a constant temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com